The problem 24 is for validating 3D nonlinear time transient codes. The user can read the document ’problem24_withResults.pdf’ to get further background information for this problem.

In this problem we switch on the Voltage in two coils to a value of

23.1 V. We calculate the time dependent current in the coils, the torque

and flux density over time.

Estimated time: 1.5 h

The task description does not give any information about the

conductivity of the coil material. Instead it provides the ohm

resistance: Both coils have 3.09 Ohm, so one will have the half of it.

To account for this given resistance in our simulation there are two

possibilities: We can either adjust the conductivity or the fill-factor

of the coil to drive the resistance to the demanded value.

So our strategy will be building up the model using standard copper and

first performing a fast static analysis to compute the ohm resistance of

the coils. This first solution will be done without rotor and stator,

just with the coils and air. Comparing this ohm value against the

demanded one will give us a scale value. This scale value can be used to

either scale the coil conductivity or the coil fill-factor. We will use

the fill-factor. After this the transient run can be done.

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.2Team24.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter 3D or NX. Use Version 12 or higher, preferably use the newest.

In Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’Team24.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

and navigate to folder ’start’. Select

the file ’Team24.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

From toolbar Application click on ’Pre/Post’ ![]()

Create a ’New Fem and Simulation File’. Preferably, activate the ’Strategy’ ’Non-Manifold’. Otherwise Mesh-Mating-Conditons must be used.

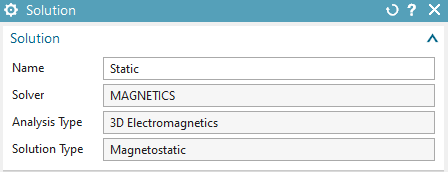

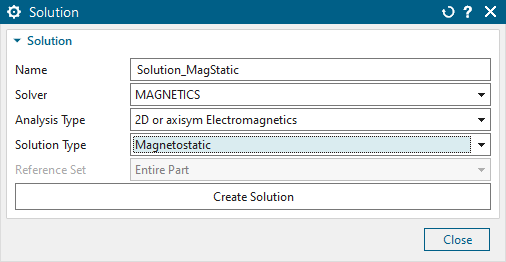

Create a first solution ![]() of type ’Magnetostatics’. This will be

the pre-solution.

of type ’Magnetostatics’. This will be

the pre-solution.

Name the solution ’Static’

Accept solver ’MAGNETICS’ and

analysis type ’3D Electromagnetics’,

In the output requests, activate the tabular results ’Electrode

Voltage’ and ’Electrode Current’ to get tabular output for voltage and

current on the coils. This will allow us to compute the ohm resistance

by the formula \(R=U/I\).

Click OK.

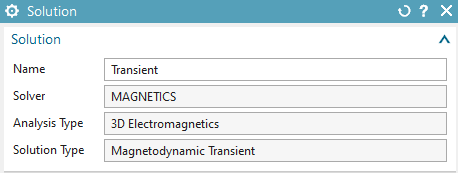

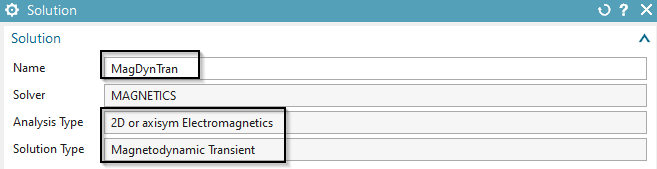

Create a second solution (in the Sim part, use button ![]() )

of type ’Magnetodynamic Transient’.

)

of type ’Magnetodynamic Transient’.

Name the solution ’Transient’

In the output requests ’Plot’, activate ’Magnetic Flux Density’

and ’Current Density’. In the ’Table’, activate ’Total Moment - entire

(virtual)’ to get tabular output of rotor torque over time steps. Also

activate ’Electrode Voltage’ and ’Electrode Current’.

Feel free to activate more results as desired.

In register ’Time Steps’, set ’Number of Time Steps’ to 20 and

’Time Increment’ to 0.01 sec.

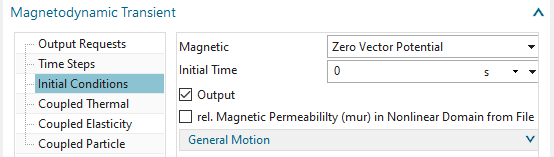

In register ’Initial Conditions’, activate ’Output’ to output the

results of time zero.

Click OK.

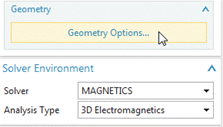

Set the Fem file to the displayed part.

Edit the Fem file and activate ’Splines’ in Geometry

Options.

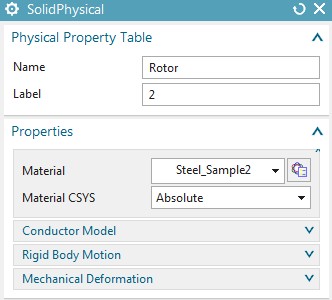

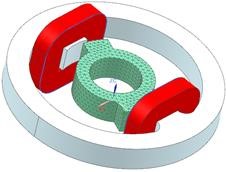

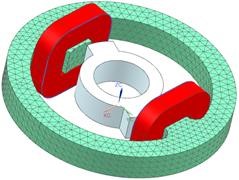

The Rotor

Mesh using tetrahedral elements with the half of the suggested element size (8.83/2 mm).

Apply material ’Steel_Sample2’ (From library

’Magnetics_Materials.xml’ in folder MAGNETICS). Notice that this

material has a nonlinear B-H curve. It contains the data of the TEAM24

task description.

The Stator

Mesh with tets and half of suggested element size (14.6/2 mm).

Apply material Steel_Sample2.

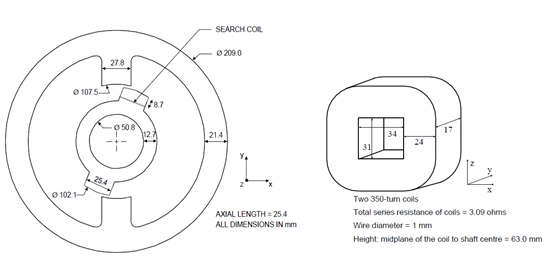

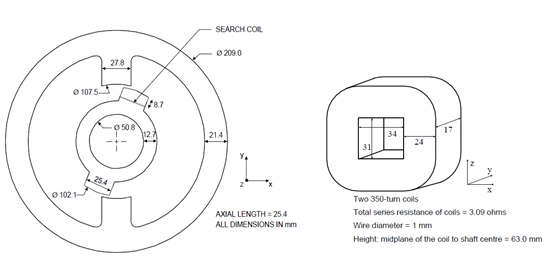

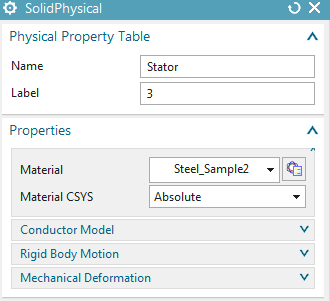

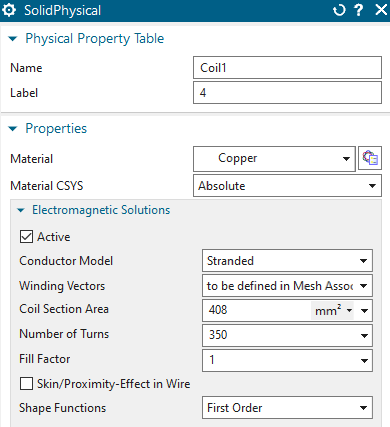

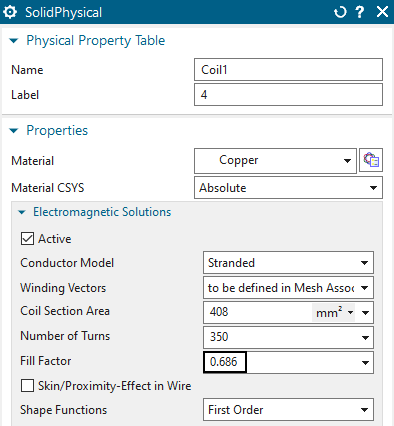

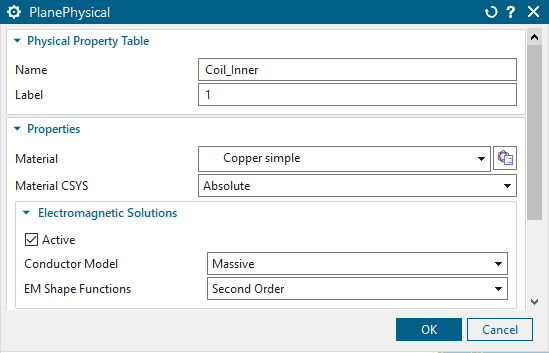

The first Coil

Mesh by tets and the suggested element size (8.92 mm).

Name the physical ’Coil1’.

Set the material to ’Copper’. Make sure this copper has a electric conductivity (58e6 S/m).

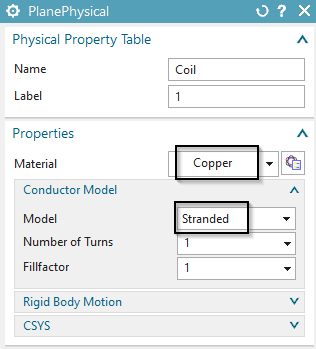

Set the ’Conductor Model’ to ’Stranded’, use 350 Turns and a Section Area of 408 \(mm^{2}\).

Accept the default ’Fillfactor’ of 1. Later we will adapt this to

drive the coil to the demanded resistivity value.

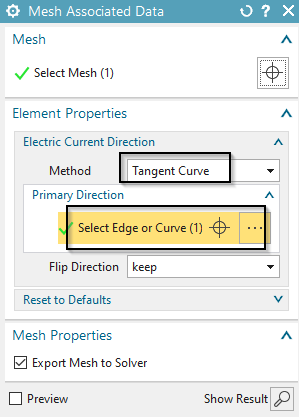

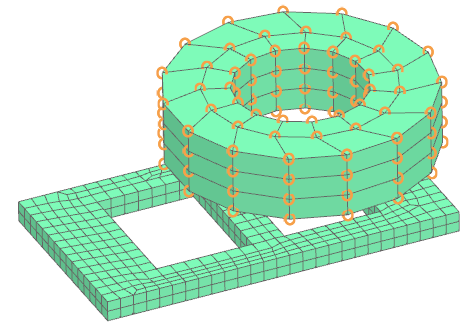

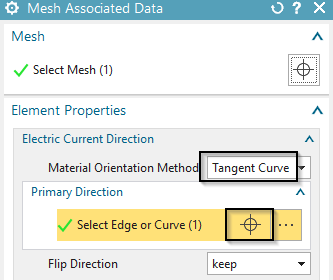

Edit the ’Mesh Associated Data’ of Coil1 mesh. Set the ’Electric

Current Direction’ option to ’Tangent Curve’ and select the spline curve

to define the direction of the windings.

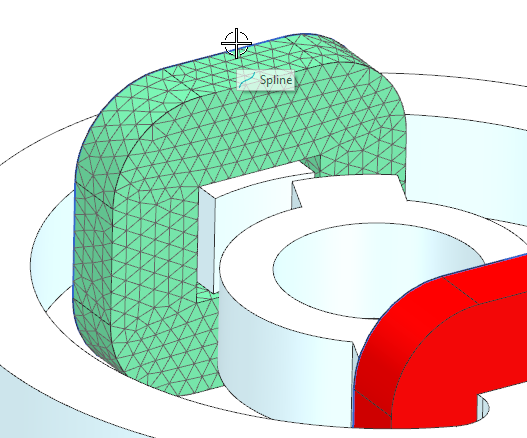

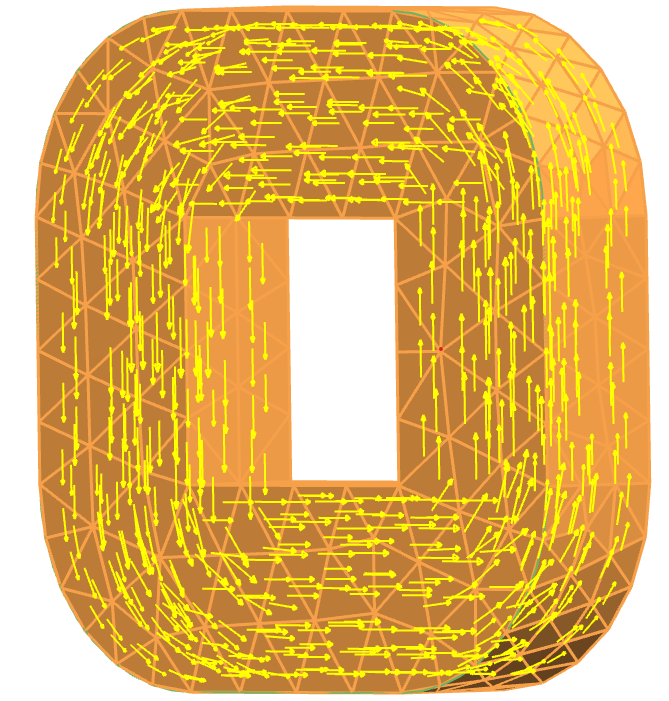

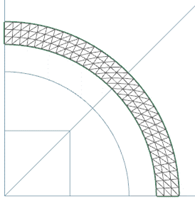

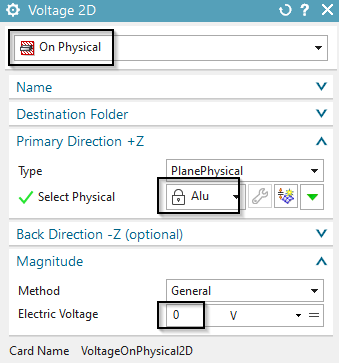

Hint: Activate ’Preview’ to check the winding direction. It

should look like the picture below.

The second coil

Use the same steps as for the first coil. Assign ’Coil2’ for name.

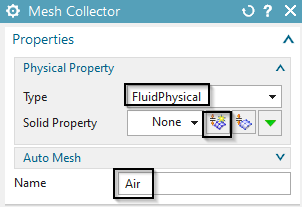

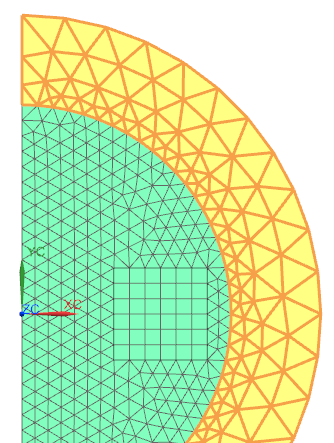

The Air:

Mesh the air volume with tets and use the suggested element size (34.5 mm).

Set the physical to ’FluidPhysical’ and assign material ’AIR’

from library

NX-folder\SIMULATION\magnet\materials\Commonly Used Materials.xml

Switch to the Sim file.

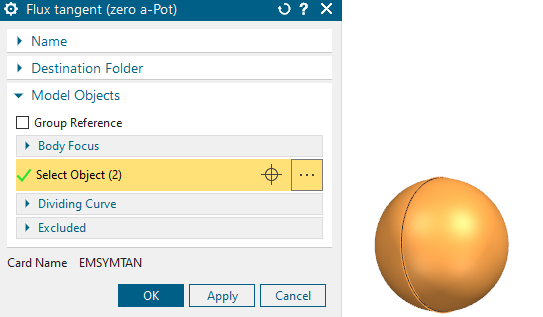

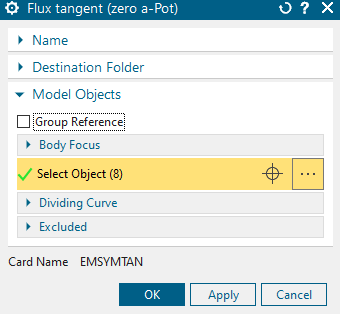

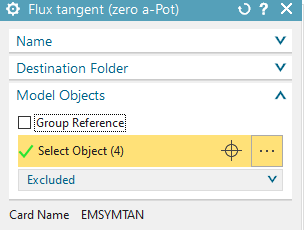

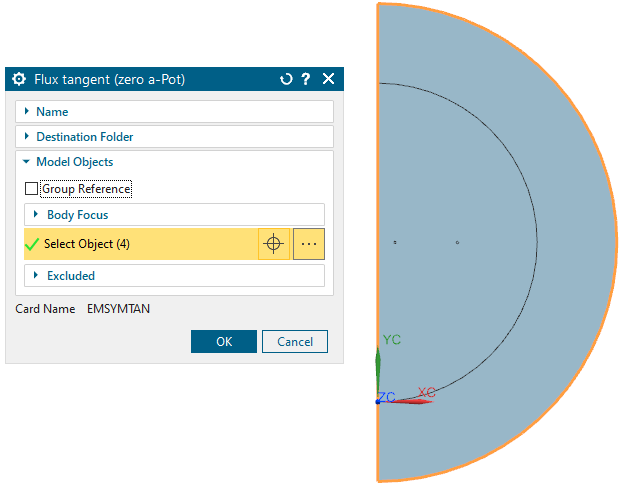

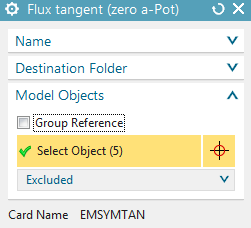

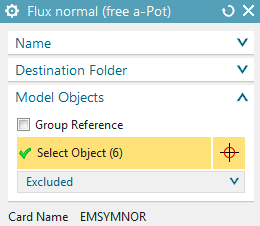

Create a constraint of type ’Flux tangent (zero a-Pot)’ on the

sphere outside faces.

Create the voltage loads.

Apply voltage load of type ’On Stranded Coil’ on the first coil.

Assign 23.1/2 V.

Apply a second voltage on the second coil with the same value.

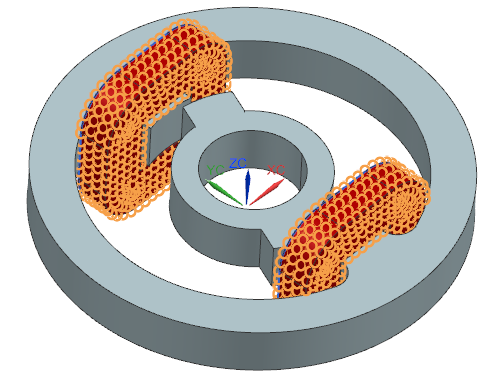

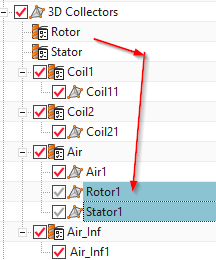

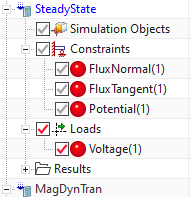

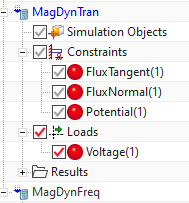

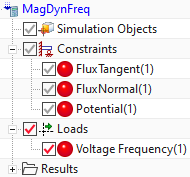

Assign these two loads and the constraint (by drag and drop) to

both solutions. The navigator should look like in the picture.

Prior to solving the static solution we must avoid that the coils are influenced by the rotor and stator. Therefore,

change to the Fem part,

drag and drop the meshes of the rotor and stator into the air

collector. Now these two will behave as air and not affect the

coils,

change back to the Sim part and solve the ’Static’ solution. The solution time should be about 0.5 minutes.

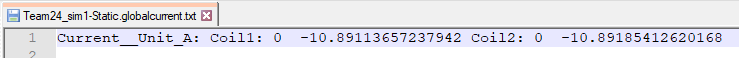

After the solve job has finished open the newly created afu- or

text file Team24_sim1-Static.globalcurrent.txt with the XY Function

Navigator or with a text editor. Find there the resulting current at the

two coil electrodes. The result is about 10.89 A.

According to \(R=U/I\) we can

compute the actual resistance to \(R=11.55 V /

10.89 A = 1.06 Ohm\). Because the demanded resistance is \(3.09/2 Ohm =1.545 Ohm\) the scale factor

becomes \(1.06 / 1.545 = 0.686\). To

use this factor as fillfactor switch to the Fem part and edit the two

physicals of the two coils. Set the ’Fillfactor’ as shown in the

picture:

Test solve again the static solution and find the new current

result as 7.47 A.

Now the resistance of the coil is R=11.55 V / 7.47 A = 1.54 Ohm as it is demanded in the Team task description.

Prior to solving the transient solution, move the two meshes of

rotor and stator back into their origin mesh collectors. Then solve. The

solution time will be about 3 minutes because of nonlinear iterations

due to saturation effects.

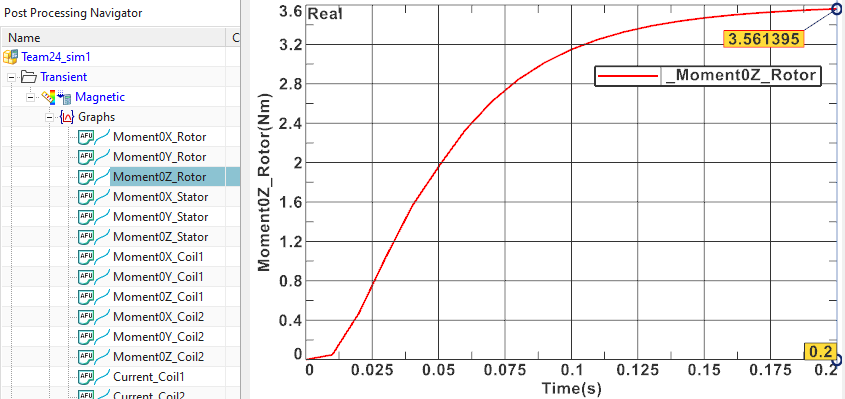

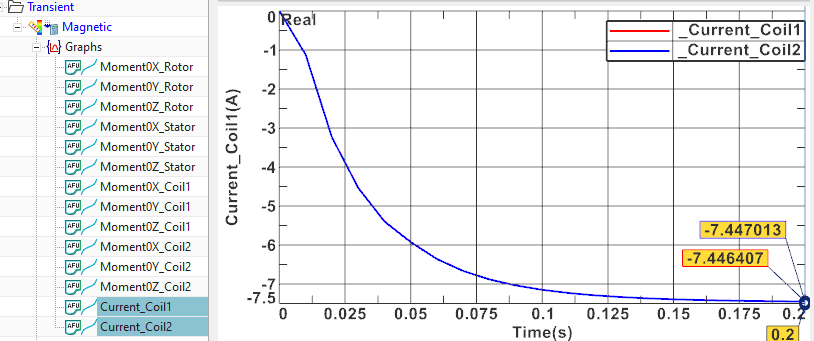

Check current and torque results over time.

Open the graphical table results and display them as follows.

Display z component of the torque on the rotor. The maximum value

is 3.56 Nm. The reference result from measurements is 3.2 Nm. Smaller

mesh sizes will drive the simulation result more and more against the

measurement.

Display the current result for both coils. They show a good

agreement and the maximum value is 7.45 A. The measured reference value

for the current is 7.4 A at time 0.2 sec.

A manual verification of the time dependent current \(I(t)\) in a coil after switching on the

voltage, is given by the formula: \[I(t) =

(1-e^{\frac {R}{L} \cdot t}) \cdot \frac{U_{0}}{R}\]

with \(R = 1.54 \Omega\), \(L = 0.03H\), \(U_{0} = 11.55V\) and \(t = 0.01s, ..., 0.2s\).

L is precalculated by the formula: \[L

\approx \mu_r \cdot \mu_0 \cdot N^2 \cdot \frac{A}{l} \approx

0.03H\]

Following a table with a comparison of the simulation and analytic

results:

| Time | Simulation Result | Analytic Result | Deviation | |

|---|---|---|---|---|

| 0.01s | 2.65A | 3.01A | \(13.6\%\) | |

| 0.05 | 6.2A | 6.92A | \(11.6\%\) | |

| 0.1s | 7.2A | 7.45A | \(3.5\%\) | |

| 0.15s | 7.38A | 7.49A | \(1.5\%\) | |

| 0.2s | 7.43A | 7.4997A | \(0.9\%\) |

The values match well at the end time. Deviations in the beginning are

higher probably because of the unsecure inductivity value of the

coils.

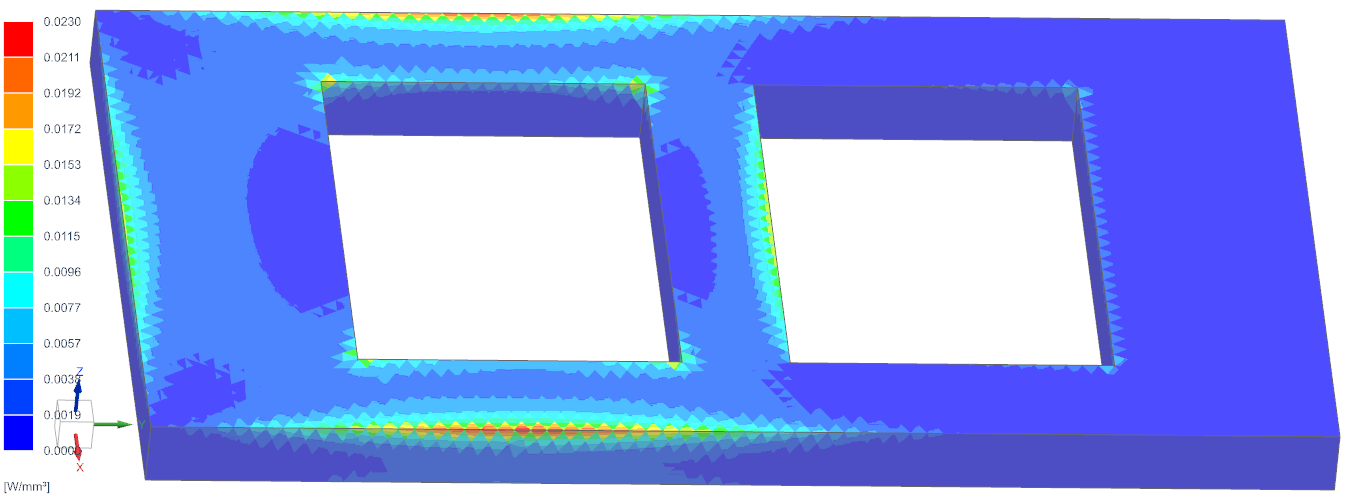

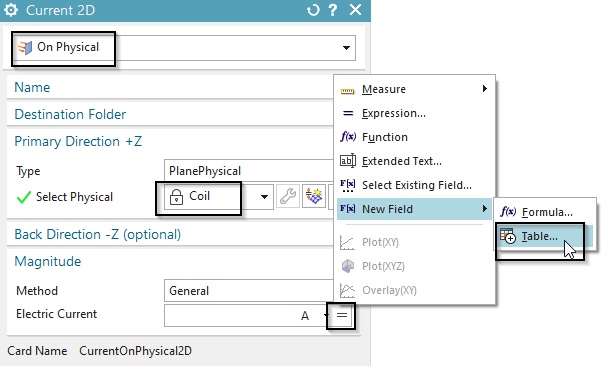

The contour plot of the flux density at time 0.2 s (last time

step) looks like this:

The tutorial is finished.

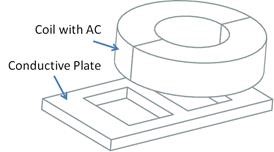

The problem 3 of the Team Benchmarks (Testing Electromagnetic

Analysis Methods) is one of the examples for testing eddy current

effects. A conductive plate with two holes is placed under a coil. The

coil is driven by alternating current of 50 Hz and 1260 ampere turns.

The goal is to analyse for the magnetic flux density along a line that

goes slightly over the plate. The user should read the documents

’problem3.pdf’ and ’Results_EddyCurrentProblems.pdf’ for more background

understanding.

What you learn in this example:

Perform 3D Magnetodynamic analysis in frequency domain,

Display and calculate the Skin depth.

Estimated time for the example: 1h.

Follow these steps:

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.3Team3.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter ![]() (or

NX). Use Version 12 or preferably newer.

(or

NX). Use Version 12 or preferably newer.

In Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’Team3_full.prt’ and click OK. (Maybe you must set the file

filter to ’prt’)

and navigate to folder ’start’. Select

the file ’Team3_full.prt’ and click OK. (Maybe you must set the file

filter to ’prt’)

From toolbar Application click on ’Pre/Post’ ![]()

Click on ’New FEM and Simulation’,

Preferably, activate ’Strategy’ ’Non-Manifold’. If not, Mesh-Mating-Conditions must be used.

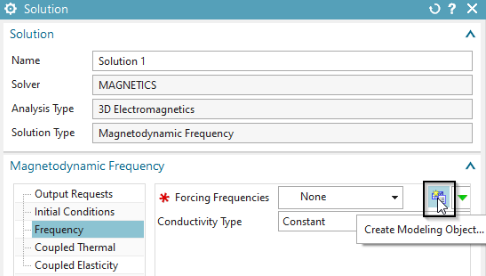

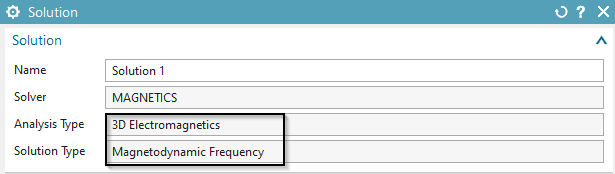

Create a new Solution

Accept the Solver ’MAGNETICS’ and choose the Analysis Type ’3D Electromagnetics’,

Choose Solution Type ’3D-Magnetodynamic Frequency’

In register ’Output Requests’, ’Plot’ set ’Current Density’ and

’Eddy Current Losses Density’ on to compute eddy current effects.

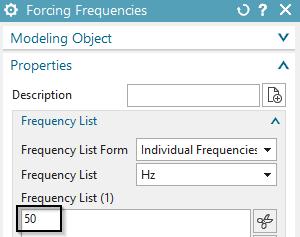

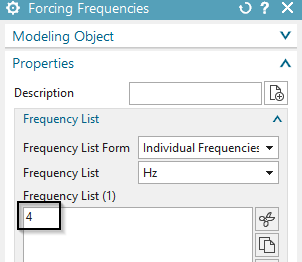

In register ’Frequency Domain’, click ’Create Modeling Object’.

In the following window ’Forcing Frequencies’, key in 5000 Hz into the

list and click OK.

Set the displayed part to the Fem-file.

The Coil:

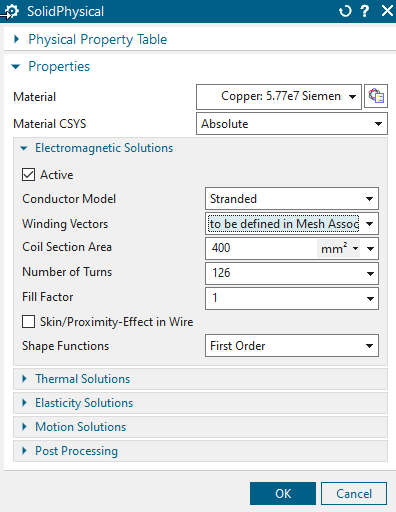

Create a 3D tetra mesh on the coil body. Select the coil, key in the source element size (half of the suggested). Click OK.

Edit the physical of the coil and assign the material Copper to it.

Set the ’Conductor Model’ option to ’Stranded’. The ’Number of

Turns’ to 126 and the ’Coil Section Area’ to \(400 mm^{2}\).

Edit the Mesh Associated Data for the coil mesh. Set the

’Material Orientation’ to ’Tangent Curve’ and select the circular edge

to describe the winding direction.

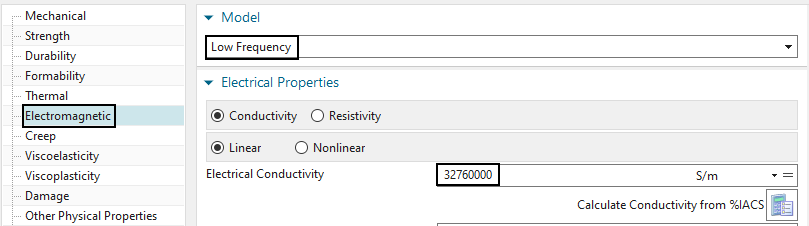

The Plate:

Create a 3D tetra mesh on the plate. Use the system suggested value/4.

Edit the physical and click ’Choose Material’![]() .

.

Click on ’Create Material’ (Bottom right)![]() .

.

Under ’View’, switch to ’All Properties’. As name, type in ’PlateSample’.

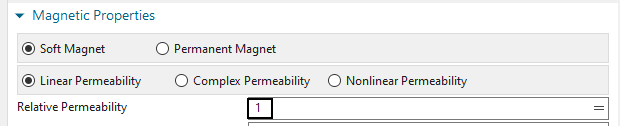

Under ’Electromagnetics’ set ’Model’ to ’Low Frequency’.

For ’Electrical Conductivity’, type in \(32760000 S/m\). And for ’Relative

Permeability’, key in 1. Click OK several times until the window

disapears.

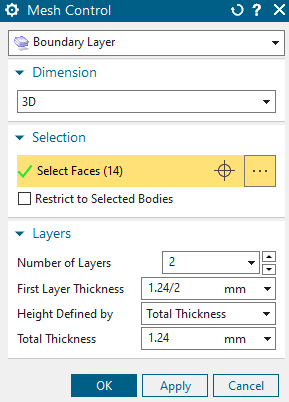

Mesh Control

Click on ’Mesh Control’ ![]() .

.

Assign ’Boundary Layer’

Select all plate faces (drag a window).

Under ’Number of Layers’, key in 1, ’First Layer Thickness’, 1.24

and ’Total Thickness’, 1.24. We do this to consider the skin depth in

this simulation. Click OK.

Hint: Because of the skin effect, eddy currents will appear mainly at

the border of the conductor. The thickness of that eddy current layer is

called Skin Depth. For a accurate simulation this skin depth should be

meshed with high quality elements. At least one layer of elements as we

do in the following. The skin depth (\(\sigma\)) can be calculated by the formula:

\[\delta = \frac{1}{\sqrt{\pi \cdot f \cdot

\mu_0 \cdot \mu_r \cdot \sigma }} = 1.24 mm\]

with \(f = 5000Hz\), \(\mu_0 = 4\pi \cdot 10^{-7}\), \(\mu_r = 1\), \(\sigma = 32760000\) S/m.

Update the FEM![]() .

.

The Air

Create a 3D tetrahedral mesh with the suggested size (24.1 mm) on

the air volume. Assign material ’AIR’ from library

NX-folder\SIMULATION\magnet\materials\Commonly Used Materials.xml

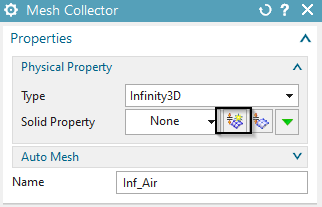

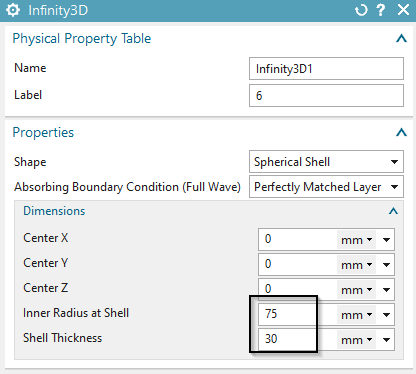

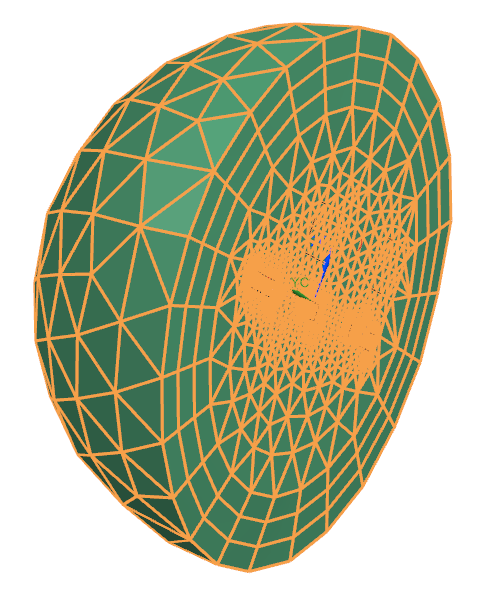

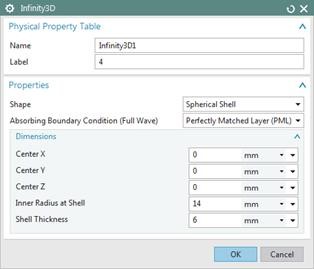

The Air Infinity

This step is optionally for higher result accuracy but it can only be done if there is a geometry for the infinity air (not the case in the geometry file): Create a 3D tetrahedral mesh and select the body ’AirInf’ (not available in current model but can be created in the prt file) and accept the suggested size. Activate ’Automatic Creation’. Click OK.

Create for this mesh a physical of type ’Infinity3D’ and

Insert the settings into the physical as shown.

Switch to the Sim-file

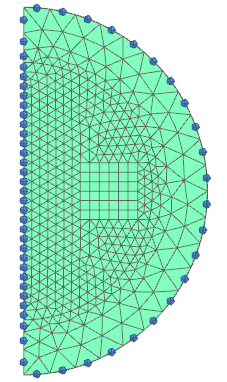

Create a constraint of type ’Flux tangent (Zero-a-Pot)’ on the

outside element faces of the Air Infinity sphere. Set the selection

filter to ’Tangent Faces’ and select a face. Click OK.

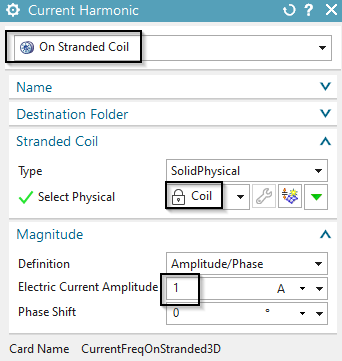

Create a load ’Current Harmonic’ with type ’On Stranded Coil’ on

the coil. Assign 10 A.

Solve the solution. The solution time is about 1 minute.

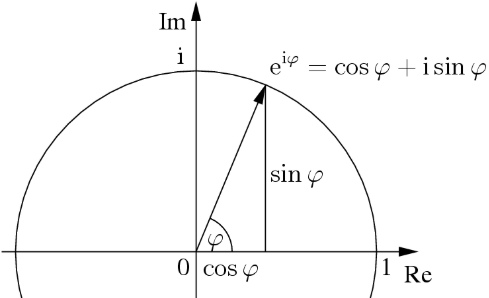

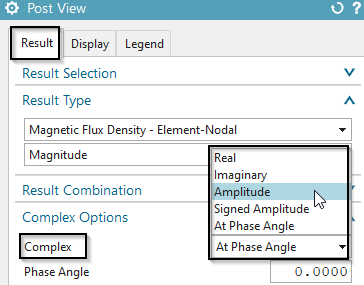

In all frequency domain solutions results are complex, that means they have a real (Re) and an imaginary (Im) part. One can imagine the corresponding time domain solution would alter between this real and imaginary part. From real and imaginary part other quantities like amplitude and phase angle can be extracted by complex number math operations.

Hints for viewing frequency results in post processing:

All frequency results are available in complex format what means

the NX postprocessor can handle these comfortably. The ’Complex Options’

can be set by first clicking ’Result’ ![]() and

then modifying the ’Complex’. That allows to switch between ’Real’,

’Imaginary’, ’Amplitude’ and ’At Phase Angle’.

and

then modifying the ’Complex’. That allows to switch between ’Real’,

’Imaginary’, ’Amplitude’ and ’At Phase Angle’.

The complex results of frequency solutions can be shown as time results. To do so, an animation over the ’Phase Angle’ must be done. This will show, step by step, how the real part changes to the imaginary part, thus, the corresponding time solution. Proceed as follows:

Set the option ’Complex’ to ’At Phase Angle’.

Click ’Animation’ ![]() and set the ’Style’ to ’Modal’.

Activate ’Full Circle’. Then click ’Play’. The animation will show the

corresponding time result.

and set the ’Style’ to ’Modal’.

Activate ’Full Circle’. Then click ’Play’. The animation will show the

corresponding time result.

In the ’Post Processing Navigator’ double click on the ’Current Density’ result.

Hide the 3D elements Coil, Air, AirInf and all 2D elements.

Current Density Result:

The picture shows the area where the eddy currents appear. It

corresponds to the prior calculated skin depth.

The picture shows the area where the eddy currents appear.

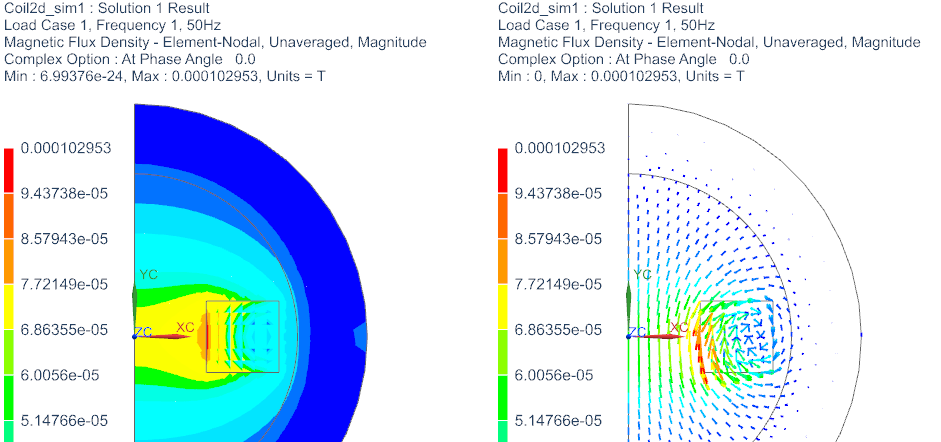

Flux density plot with arrows and the ’Complex Option’ is set to

’At Phase Angle’. Visible is the magnetic field, created by the coil and

influenced by the plate.

EddyCurrentLossesDensity:

This result is responsible for the heating of the plate.

This result is responsible for the heating of the plate.

In this second part of the exercise we will demonstrate how conducting sheets can be used. Therefore, the aluminum plate will be modeled by 2D elements which take into account thickness and magnetic/electric material properties. This assumption is valid and of good accuracy if thickness is small. The model is already set up, so in this tutorial we simply walk through the steps and check the new features.

Open the part ’Team3_sim2.sim’ from the complete folder and

change to the FEM file. The part already contains a coarse mesh,

physical properties and boundary conditions for this exercise.

Set the Fem file to the displayed part.

Edit the FEM file and verify the solver is set to MAGNETICS and

the analysis type is ’3D Electromagnetics’.

Notice the plate is meshed by 2D elements. The mesh resides in a

collector named ’PlateThin’. Check the physical of the plate. It is of

type ’SheetPhysical’ and materials and thickness properties are defined

as shown in the picture below:

Notice that in this example we used a ’Solid from Shell Mesh’ for the air. Therefore, a ’Surface Coat Mesh’ on all 3D parts exists (collector ’NotToSolver’) and a tri mesh on the air boundary (collector ’Env’).

Check the 2D mesh collector ‘Env’. It contains a physical of type

ZeroPotential’ for the boundary. This physical has the same effect as a

constraint of type ’Flux tangent (zero a-Pot)’ in the Sim file. You can

use this alternatively. Its advantage is a little more performance when

writing out the solver input file.

Check the physical for the coil mesh. All properties are set in the same way as in the first part of this example (126 turns, \(400mm^{2}\) section area). Also the definition of the winding directions is already there.

Check the FluidPhysical for the air mesh.

Change to the Sim file.

The solver is Magnetics, Analysis type is 3D and Solution Type is

’Magnetodynamic Frequency’. All settings are set in the same way as in

the first part of this example.

The same current (10 A) is applied on the coil.

There is NO ’Flux Tangent (zero a-Pot)’ condition in the SIM file, because there is already a ZeroPotential physical that has the same function.

Solve and post process the results.

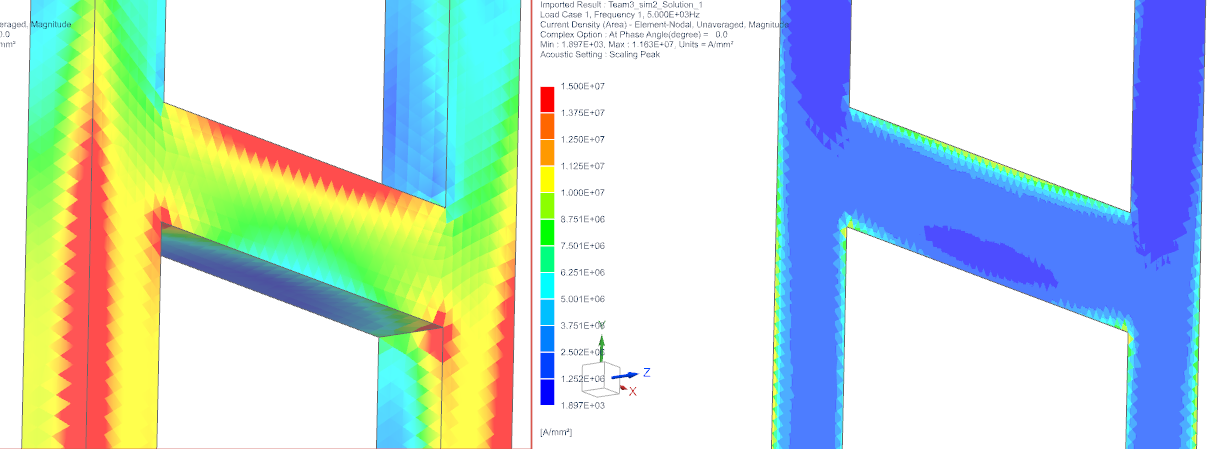

Check Current Density in comparison of the 3D plate with the 2D

sheet: See next picture (left 3D plate, right 2D sheet):

The overall agreement is ok, but notice there are deviations

between the 3D and the thin sheet results that result from edge effects.

The 3D results are more precise. The skin effect is more detailed using

the 3D plate model. Deviations become smaller with thinner plates.

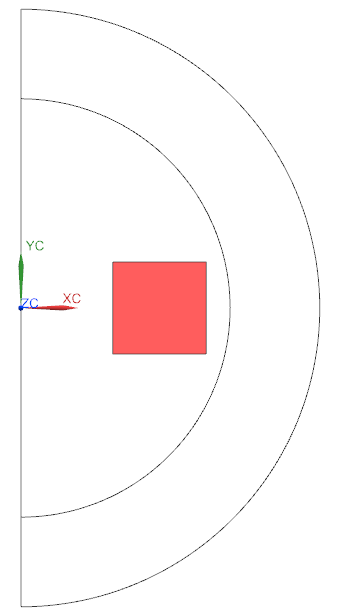

In case the model and also the magnetic field are symmetric, the

simulation can be simplified. We use a half model and apply a symmetry

constraint on the symmetry plane.

The condition ’Flux tangent (zero a-Pot)’ on the symmetry plane acts as

a symmetry condition. Therefore, that condition has to be defined on all

outside faces: The outside sphere faces and the symmetry plane.

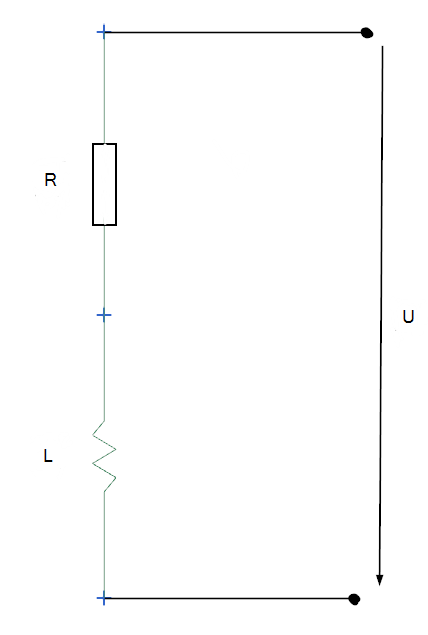

In this example we show how to calculate inductance, ohm resistance,

voltage, current and their phase shift in a simple coil. We start with a

1D simulation where we assign the values of current, inductivity and

resistance. The simulation calculates the resulting voltage. In a

similar way one could also set up much more complex electrical circuits

and compute for such results. Following we simulate this in a 2D

axisymmetric and also a 3D simulation. The advantage of 2D and 3D

simulation is that the parameters of the coil are calculated with the

given geometry by FEM. Another possibility is to combine 1D circuits

with 2D and 3D models, what is not shown in this tutorial.

Estimated time: 1 h.

Start the Program Simcenter 3D or NX. Use Version 12 or preferably newer.

Create a new .prt file. Name it ’Coil1d.prt’

Start the application Pre/Post and click ’Create New FEM and Simulation’

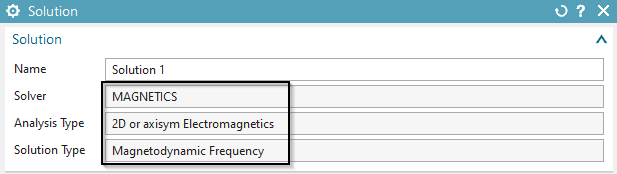

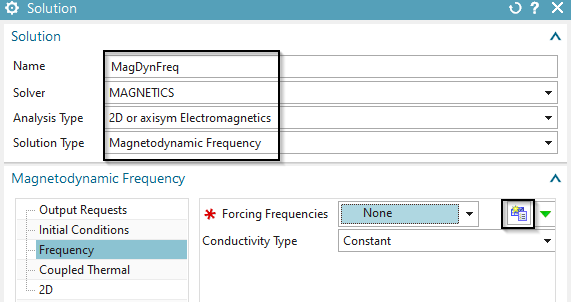

Choose solver ’MAGNETICS’ and Analysis Type ’3D Electromagnetics’(’2D or axisym Electromagnetics’ is also possible). Click OK. Deactivate ’Create Idealized Part’, click ’Create Solution’.

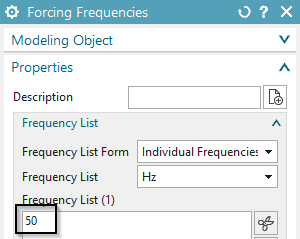

Set Solution Type to ’Magnetodynamic Frequency’.

In register ’Output Requests’ in box ’Table’ activate ’Circuit Voltage’ and ’Circuit Current’.

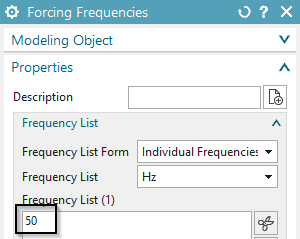

In register ’Frequency Domain’, create a modeling object and set

the ’Forcing Frequency’ to 50 Hz(Picture below).

Switch to the Fem-file.

From toolbar ’Home’ create a ’1D Connection’

Switch from ’Node to Node’ to ’Point to Point’

In ’Source’ open the ’Point Dialog’ and key in ’100’ for the X coordinate. Accept ’0’ for Y and Z. Do the same in ’Target’ with X = 100, Y = 100, Z = 0. (Any other coordinates are possible)

Under ’Element Properties’ switch to ’Inductor’.

Click OK. There now appears a symbol of the inductor between the two points.

In the Simulation Navigator double click on the created mesh collector ’Inductor(1)’.

Click edit.

In ’Nominal Values’ key in ’1’ H.

Create again a 1D Connection.

As ’Source’ use the first Point. As ’Target’ create a new point with X = 100, Y = 200, Z = 0.

Switch the type of the ’Connection Element’ to ’Resistor’. Click OK. The symbol of the resistor is a straight line.

Edit the properties of the resistor. Type ’1’ \(\Omega\) in ’Electric Resistance per Element’.

Switch to the Sim-file.

Create a new Load. Use ’Current Harmonic’.

Switch from ’On Stranded Coil’ to ’On Circuit’

For the ’Primary Node’ select the point at the bottom of the inductor. For the ’Secondary Node’ select the point on top of the resistor.

Set the ’Electric Current Amplitude’ to ’3’ A. Click Ok

Click RMB on the Solution, select ’Edit Solver Parameters’. In box ’General’ at ’Result Graphs (afu) switch to ’Create, keep txt Files’. Ok Solve the Solution.

Post-processing is done by some text or afu files that contain the results.

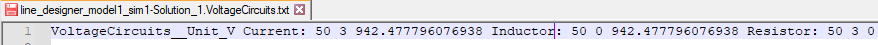

Open the file with extension *.VoltageCircuits.txt. The Solution

is divided in the applied voltage, the ’Inductor Element’ and the

’Resistor Element’. Each has three parameters. The first is the

frequency following the real part and last the imaginary part.

Applied voltage: real part = 3V, imaginary part = 942.48 V.

Inductor: real part = 0 V, imaginary part = 942.48 V.

Resistor: real part = 3 V, imaginary part = 0 V.

Impedance of the inductor: \(Z_{L} =

U/I = (0V + j942.48V)/3A\)

Impedance of the resistor: \(Z_{R} = U/I = (3V

+ j0V)/3A\)

Impedance of circuit : \(Z_{RL} = Z_{L} +

Z_{R} = 1 \Omega +j100 \pi \Omega\)

For the calculation of the voltage in the coil we need the ’reactive’

resistance of the coil \(X_{L}\). This

is calculated by: \[X_{L} = j \omega L = j

\cdot 2 \pi \cdot f \cdot L = j100 \pi\] with \(f=50Hz\) forcing frequency, \(L=1H\) inductivity of coil.

To calculate the voltage we use \(U = X_{L}

\cdot I = j100 \pi \cdot 3A = 942.478V\)

The resistance of the resistor was set to \(R

= 1 \Omega\).

So the voltage in the resistor is \(U = R

\cdot I = 1 \Omega \cdot 3A = 3V\)

These results match with the results of the simulation.

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.4Coil.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter 3D or NX. Use Version 12 or preferably newer.

In Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’coil2D.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

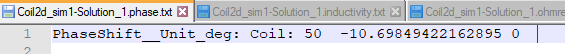

and navigate to folder ’start’. Select

the file ’coil2D.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

Start the application Pre/Post.

Create a New Fem and Sim. Set the solver to ’MAGNETICS’ and Analysis Type ’2D or axisym Electromagnetics’. Click OK.

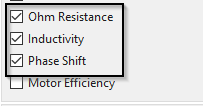

A new window appears asking for the solution type. See below.

Set the Solution Type to ’Magnetodynamic Frequency’.

In register ’Output Requests’, ’Table’ activate ’Ohm Resistance’,

’Coil Inductivity’ and ’Phase Shift’,

In register ’Frequency’ create a modeling object for ’Forcing

frequencies’ with 50 Hz.

In register ’2D’ activate ’Axisymmetric’ and click OK.

Switch to the FEM file.

Mesh the conductor face using quad elements and the suggested element size /2.

Assign ’Copper’ material and set the ’Conductor Model’ to

’Stranded’.

Mesh the air face using tri elements (half of suggested size) and assign ’Air’.

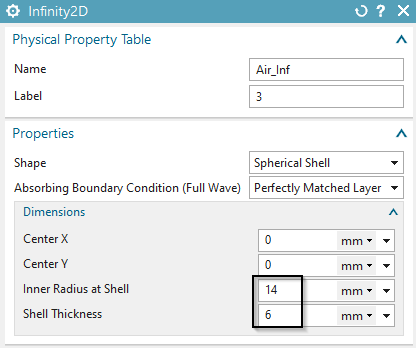

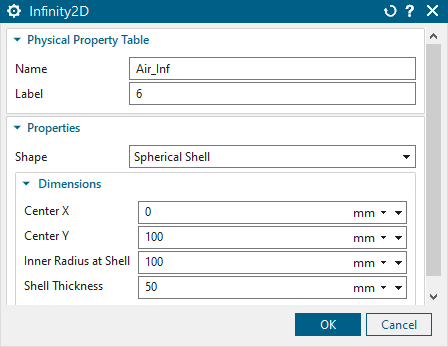

Mesh the Infinity area with tri elements (suggested element

size). Assign a physical of type ’Infinity2D’ and use the dimensions as

shown in the picture.

For easier post processing, click on the button ’Rename Meshes

...’ ![]() from the Magnetics toolbar. That

utility renames all meshes and therefore is a useful feature especially

with larger models and many meshes.

from the Magnetics toolbar. That

utility renames all meshes and therefore is a useful feature especially

with larger models and many meshes.

Switch to the Sim file.

Create a Constraint of type ’Flux tangent (zero a-Pot’ at the

middle axis and on the circular border.

Create a Load of type ’Current Harmonic 2D’ with type ’Current’

on the conductor face. Assign an Electric Current of 1 A and a Phase

Shift of zero deg.

Under Solution, select ’Edit Solver Parameters’ and modify the field Result Graphs (afu) to ’Create, keep txt Files’.

Solve the solution.

Check the flux density result. (real part)

Postprocessing is done by some text or afu files that contain the results.

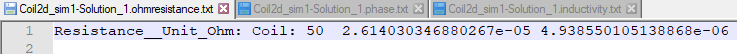

Ohm-Resistance Result

Open the file with extension *.ohmresistance.txt. There are two results for each region. The first one is the ’Active Resistance’ (Wirkwiderstand) and the second is the ’Reactive Resistance’ (Blindwiderstand). The resistance is derived from the voltage and current results by \(R=U/I\). On region ’Current(1)’ the result is

’Active Resistance’: \(2.6\mathrm{e}{-5}\) Ohm

’Reactive Resistance’: \(4.9\mathrm{e}{-6}\) Ohm .

This result is valid for a coil with one winding. For a coil with

N windings you can set the ’Number of Turns’ in the conductor properties

to the desired N. Alternatively the result values can be multiplied by

\(N^{2}\).

Inductance Result

Open *.inductivity.txt.

The Inductance is derived from the voltage and current results by

\(L=(U/I)/(2Pi*f)\). On region ’Coil’

the result is \(1.57\mathrm{e}{-9}\)

Henry. Again this result is valid for a coil with one winding. For a

coil with N windings the result value has to be multiplied by \(N^{2}\).

Phase Shift Result

Open *.phase.txt.

The phase shift is derived from voltage results by \(Phi=arctan(U_{imag}/U_{real})\). On region

’Coil’ the calculated phase shift is 6 deg. This result does not depend

on the number of windings.

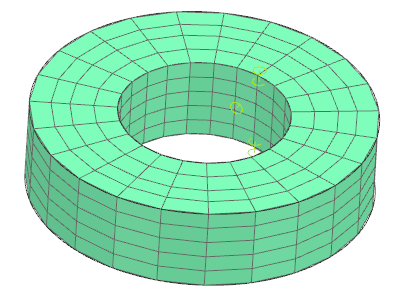

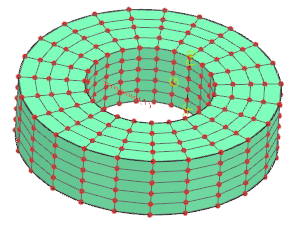

Open the part ’coil3d.prt’,

Start Simcenter Pre/Post, Create New FEM and Sim,

Choose solver ’MAGNETICS’ and Analysis Type ’3D Electromagnetics’.

Set Solution Type to ’Magnetodynamic Frequency’.

In register ’Output Requests’ under ’Table’ activate the shown

options

In register ’Frequency Domain’, create a modeling object and set

the ’Forcing Frequency’ to 50 Hz.

Switch to the Fem-file.

Create Mesh-Mating Conditions.

Hex-mesh the coil: Use the half of the suggested element-size

(4.62/2 mm). Assign material ’Copper’ and the settings as shown in the

next picture.

Assign vectors to the coil mesh.

Tet-mesh the air: Use the suggested element-size (4.92 mm). Hint: Activate the ’Pyramid Transition’ option for correct transition between hex and tet elements.

Assign material ’Air’.

Use the function ’Extrude’ from toolbar ’Nodes and Elements’ to

create 3 layers of infinity elements. Use a distance of 2 mm for each

layer. Insert the settings to the Infinity physical as shown in the

picture.

Switch to the Sim-file

Create a constraint ’Zero Potential - Flux tangent’ on the outside element-faces of the sphere.

Create a load of type ’Current Harmonic’ on any of the faces of

the coil. Assign 1 A and zero phase shift.

Under Solution, select ’Edit Solver Parameters’ and modify the field Result Graphs (afu) to ’Create, keep txt Files’

Solve the solution

Postprocessing is done by some text files that contain the results.

Voltage Result

Open *.globalvoltage.txt .

There are two values for each region. (the very first value is the forcing frequency) The first is the calculated ’Active Voltage’ (Wirkspannung) and second is the ’Reactive Voltage’ (Blindspannung). On region ’Coil’ the result is

’Active Voltage’ (Wirkspannung): -2.58e-5 V

’Reactive Voltage’ (Blindspannung): -4.66e-6 V .

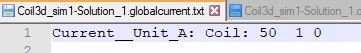

Current Result

Open *.globalcurrent.txt.

Again there are two results for each region. The first is the

’Active Current’ (Wirkstrom) and the second is the ’Reactive Current’

(Blindstrom). Because in our example we have a series circuit

(Reihenschaltung) of inductivity and ohm-resistance the reactive current

has to be zero. The sum of all active currents has to be zero, region

’Coil’ has 1 Ampere.

Ohm-Resistance Result

Open *.ohmresistance.txt.

Again there are two results for each region. The first one is the ’Active Resistance’ (Wirkwiderstand) and the second is the ’Reactive Resistance’ (Blindwiderstand). The resistance is derived from the voltage and current results by \(R=U/I\).

This ohm resistance result is valid for a coil with one winding.

For a coil with N windings the result values have to be multiplied by

\(N^{2}\).

Inductance Result

Open *.inductivity.txt.

Again there are two results for each region, but in this case the second one does not have a meaning. The Inductance is derived from the voltage and current results by \(L=(U/I)/(2Pi*f)\).

This result is valid for a coil with one winding. For a coil with

N windings the result value has to be multiplied by \(N^{2}\).

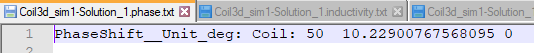

Phase Shift Result

Open *.phase.txt.

Again there are two results for each region, but in this case the

second one does not have a meaning. The phase shift is derived from

voltage results by \(Phi=arctan(Uima/Ureal)\).

For approximate analytic calculation of the inductance \(L\) of an air-coil, we use the following

formula (Source: G. Schenke, Bauelemente der Elektrotechnik 2008, S.

37.) \[L \approx \mu_0 N^2 0.51 D_{out} =

1.589 \cdot 10^{-8} H\] with \(D_{out}=0.0248 m\): Diameter of coil, \(N=1\) Number of turns, \(\mu_0=4 \pi 10^{-7}\) Magnetic

constant

The active ohm resistance \(R\) (Re

part) can be calculated from the length \(l\) and section area \(A\) of the wire and the electric

conductivity \(\sigma\) as \[R = \frac{l}{\sigma A} = 2.62 \cdot 10^{-5}

\Omega\] with \(\sigma=58 \cdot 10^6

S/m, l=0.058m, A=3.8438 \cdot 10^{-5} m^2\)

The reactive ohm resistance \(XL\) (Im

part) can be calculated from the inductance \(L\) and the frequency \(f\) from \[XL =

\omega L = 2 \pi \cdot f \cdot L = 4.99\cdot 10^{-6} \Omega\]

with \(f=50Hz, L=1.589\cdot 10^{-8}

H\).

The phase shift \(\varphi\) results

from the two resistance values by \[\varphi =

\arctan \frac{Im}{Re} = 10.7 deg\]

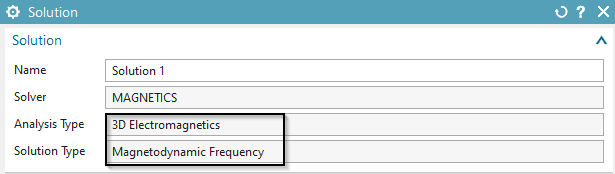

Finally, an overview of the calculated results in 2D and 3D and analytic

is shown.

| Ohm Resistance (active) | Ohm Resistance (reactive) | Inductance | Phase Shift | |

|---|---|---|---|---|

| Analytic | \(2.62 \cdot 10^{-5} \Omega\) | \(4.99 \cdot 10^{-6} \Omega\) | \(1.589 \cdot 10^{-8} h\) | \(10.7 \deg\) |

| 2D | \(2.614 \cdot 10^{-5} \Omega\) | \(4.938 \cdot 10^{-6} \Omega\) | \(1.572 \cdot 10^{-8} h\) | \(10.698 \deg\) |

| 3D | \(2.581 \cdot 10^{-5} \Omega\) | \(4.658 \cdot 10^{-6} \Omega\) | \(1.483 \cdot 10^{-8} h\) | \(10.23 \deg\) |

As another reference, the benchmark example ’TEAM 15’ gives an inductance value for a similar coil with N=3790 windings as \(0.2218 h\). In our 2D example we calculated \(0.2258 h\). Thus, the deviation in 2D is 1.8% and in 3D 4%.

The exercise is done. Save your files and close them.

When conductive solid objects move through a static magnetic field,

eddy currents are induced according to Faraday’s law. The induced eddy

current density interacts with the static magnetic field, resulting in a

Lorentz force that acts on the solid and opposes its motion. Thus, a

conducting solid vibrating in a static magnetic field experiences

structural damping.

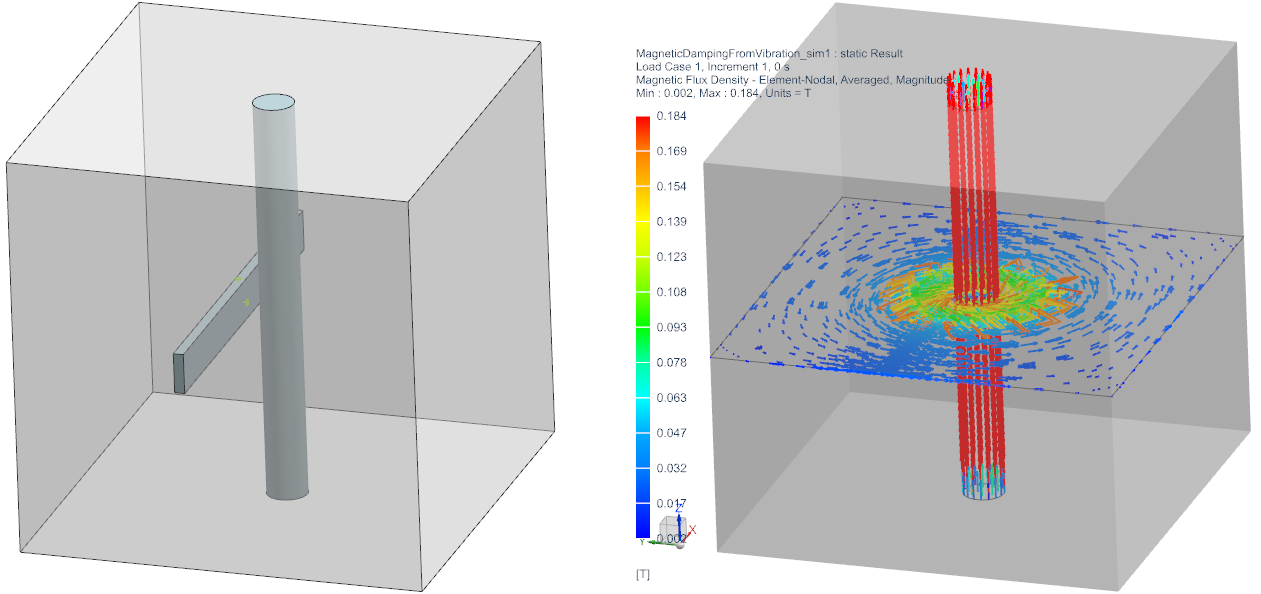

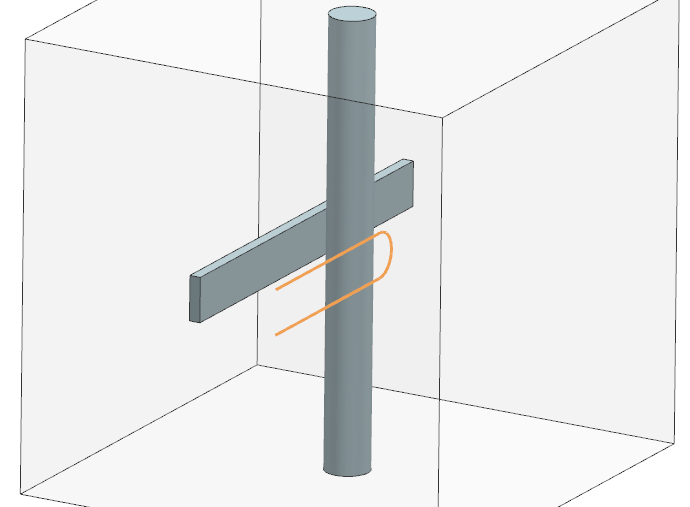

This example calculates the damping effect when a cantilever beam (an

electric conductor) is subjected to harmonic excitation across a range

of frequencies while placed in a strong magnetic field. The approach

used here assumes that the shape of the conductor does not change, thus

structural displacements remain small.

The above picture right shows a current-wire that creates a magnetic

field around it. A conductor is placed near to it. With static current

and without any conductor-motion there will be no eddy currents and

forces. The below picture shows the magnetic field, eddy currents and

forces if the conductor moves.

In electromagnetic simulations, such movements can be modeled in two

ways: either by using step-by-step motion with moving meshes or by

incorporating the motion directly into the equations, which is a much

simpler approach. This is the method we want to use here. The feature to

be used for that is "Conductor Motion - const Shape".

Neglecting the displacement currents, we have to solve Maxwell’s equations together with the following constitutive relations: \[\text{curl}\,h = j \quad \quad \text{curl}\,e = -\partial_{t} b \quad \quad \text{div}\,b = 0\] \[b = \mu \, h \quad \text{and} \quad j = \sigma \, e\]

\(h\): magnetic fieldstrength, \(b\): magnetic fluxdensity, \(j\): electric currentdensity, \(\mu\): magnetic permeability, \(e\): electric fieldstrength, \(a\): magnetic vectorpotential, \(v\): electric scalarpotential, \(\sigma\): electric conductivity

The weak a-v form becomes (with \(b = curl \,a\) and \(e = -\partial_{t} a - grad \,v\)) \[(1/\mu \,curl \,a, curl \,a^{‘}) + (\sigma \, \partial_{t} a, a^{‘}) + (\sigma \,grad \,v, a^{‘}) + (\sigma \,\partial_{t} a, grad \,v^{‘}) + (\sigma \,grad \,v, v^{‘}) = 0\]

The last two terms represent Ohm’s law. In the formulation of the

physical master-library (file lib_Master.pro) each of such terms is

written as a equation line as follows:

Equation{

Integral{ [ 1/mu[] * Dof{Curl a}, {Curl a} ]; ...};

Integral{ DtDof[ sigma[]* Dof{a} , {a} ]; ...};

Integral{ [ sigma[]* Dof{Grad v}, {a} ]; ...};

Integral{ DtDof[ sigma[]* Dof{a} , {Grad v} ]; ...};

Integral{ [ sigma[]* Dof{Grad v}, {Grad v} ]; ...};

... }

Ohm‘s law \(j = \sigma \,e\) is only

valid for non-moving conductors. For a conductor moving at velocity

\(vel\), ohm’s law becomes \[j = \sigma \,(e + vel \times b)\] Thus,

the fourth and fifth equation terms are extended and (again with \(e = -\partial_{t} \,a - \text{grad} \,v\))

become the last three lines of the following set. Finally, we have one

additional line to represent the speed term:

Equation{

Integral{ [ 1/mu[] * Dof{Curl a}, {Curl a} ]; ...};

Integral{ DtDof[ sigma[]* Dof{a} , {a} ]; ...};

Integral{ [ sigma[]* Dof{Grad v}, {a} ]; ...};

Integral{ DtDof[ sigma[]* Dof{a} , {Grad v} ]; ...};

Integral{ [ sigma[]* Dof{Grad v}, {Grad v} ]; ...};

Integral{ [-sigma[]* (vel[] *^ Dof{d a}), {a} ]; ...}; /*SpeedTerm*/

... }

The speed term \(vel[]\) is defined as

a function. This allows to use either fixed velocity-values or spacial

distributions or even flow fields resulting from CFD. Algorithms are

implemented that allow reading such fields and also interpolating on new

meshes. By this way each element’s velocity contributes to the

electromagnetic solution.

Download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.11MagneticDampingFromVibration.zip

Unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter or NX. Use Version 12 or preferably newer.

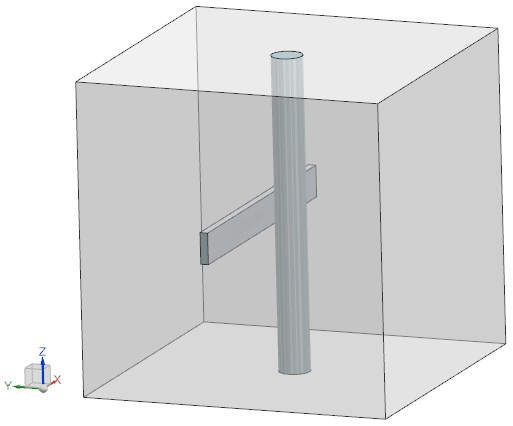

In Simcenter, click ’Open’ and navigate to folder ’start’. Select the file ’MagneticDampingFromVibration.prt’ and click OK. (Maybe you must set the file filter to ’prt’)

Start the Application Pre/Post.

Click ’Create a New Fem and Sim’.

Deactivate ’Create Idealized Part’

Set the solver to ’MAGNETICS’ and Analysis Type to ’3D Electromagnetics’

Hint: Leave the option ’Strategy to Use’ at the default ’Manifold’ (If working in a newer version of NX, in an older this does not exist). We will use this older process because it is compatible in all versions even if the newer ’Non Manifold’ would make the meshing simpler.

Click Ok

If a new window appears asking for the solution type, click ’Close’. We want to create the solution later.

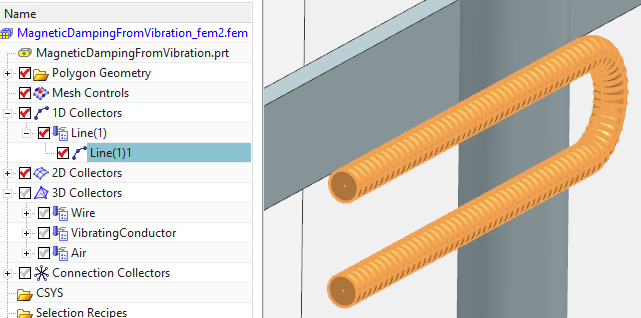

There is nothing special in the Fem part. Just creating standard meshes, mesh-matings and assigning materials. If desired, the user can alternatively start with the existing Fem part from folder completed and create a Sim part from that.

Create mesh-matings

Click ’Mesh Mating’ and Ok. There will be 6 conditions created.

Create meshes

Make the Fem part to the displayed part.

Click ’3D Tetrahedral’ and select the Wire geometry. Click ’Automatic Element Size’ and use the given value divided by two (72.8/2 mm). Click Apply to create the mesh

Select the Vibrating_Conductor geometry, also use the automatic element size divided by two (61.9/2 mm). Active here the option ’Minimum Two Elements Through Thickness’. Click Apply

Select the Air geometry and also use the given value divided by two (203/2 mm). Click Ok

Apply material to the Wire

Edit the mesh collector that contains the Wire mesh.

Key in the name ’Wire’ (if not automatically done)

In the collector window, accept the default Physical Property Type ’SolidPhysical’

Click ’Edit Physical’

in the box ’Material’, activate ’Built-In’ and set the material to ’Copper’.

Click Ok, Ok to close the dialogues.

Apply material to the Vibrating Conductor

Edit the mesh collector that contains the Vibrating_Conductor mesh.

Key in the name ’VibratingConductor’ (if not automatically done)

In the collector window, accept the default Physical Property Type ’SolidPhysical’

Click ’Edit Physical’

in the box ’Material’, activate ’Built-In’ and set the material to ’Aluminum’.

Click Ok, Ok to close the dialogues.

Apply material to the Air

Edit the mesh collector that contains the Air mesh.

Key in the name ’Air’ (if not automatically done)

In the collector window, change the Physical Property Type to ’FluidPhysical’

Click ’Create Physical ...’

in the box ’Material’, activate ’Built-In’ and accept the default

material ’Air’.

Alternatively, select ’AIR’ from library

\NX-folder\SIMULATION\magnet\materials\Commonly Used Materials.xml

Click Ok, Ok to close the dialogues.

Conductor motion or speed affects dynamics and thus the simulation must be done in one of the dynamic solution-types. That even applies if the conductor moves through a static magnetic field. Thus, in this first step we do a usual transient electromagnetic solution. The disadvantage is that in transient solutions there are some time steps necessary for the fields to become nearly static. So, lets try with a time of one second and 10 steps:

Create the solution

Click ’Solution’ and set the ’Solution Type’ to ’Magnetodynamic Transient’

Key in as name ’Transient const speed’

in register ’Output Requests’, box ’Plot’, activate ’Magnetic Fluxdensity’, ’Current Density’ and ’Lorentz Force (j x b)’

in register ’Time Steps’, set the ’Time Increment’ to 0.1 s and the ’Number of Time Steps’ to 10.

Click Ok to create the solution

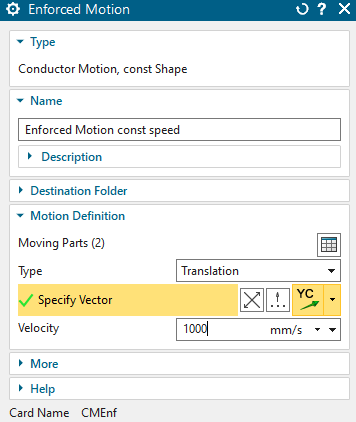

Create the speed:

Click ’Simulation Objects’, ’New Simulation Object’, ’Enforced Motion’

set the Type to ’Conductor Motion, const Shape’

key in at name ’Enforced Motion const speed’

in box ’Motion Definition’, at ’Moving Parts’, click ’Create Moving Parts...’

in the next window in box ’Selection’, select the ’VibratingConductor’ and click ’Add’ (right to the box ’List’). Then click ’Close’

back in the window ’Enforced Motion’, set the ’Type’ to ’Translation’ (the default)

at ’Specify Vector’ assign the YC direction

at ’Velocity’, key in 1000 mm/s.

Click Ok to finish the motion object.

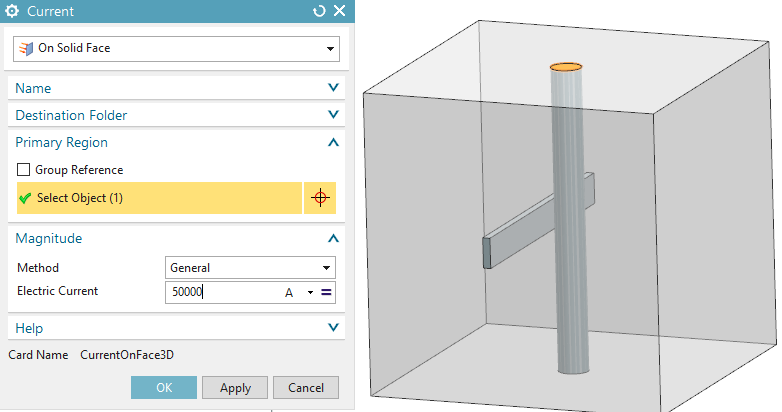

Apply constant current on the wire to get a rotating magnetic field.

create a load of type ’Current’, set the type to ’On Solid Face’,

select the face as shown in the below picture, key in 50000 A and click

Ok.

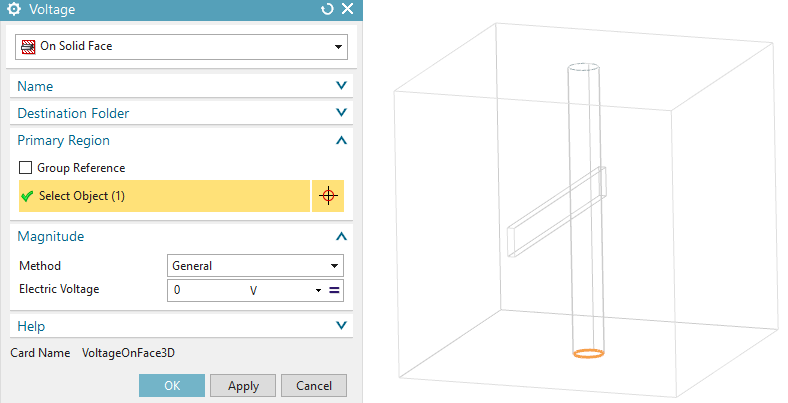

create a load of type ’Voltage’, set the type to ’On Solid Face’,

select the face as shown in the below picture, key in 0 V and click

Ok.

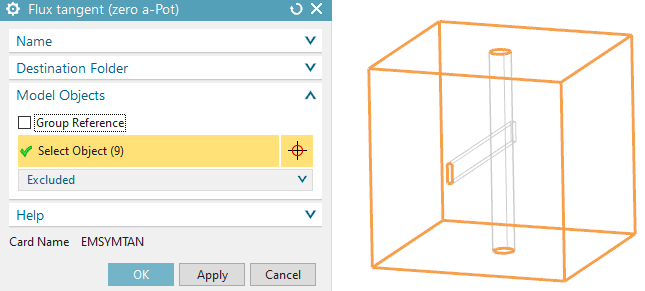

Apply a zero potential constraint at the outside

create a constraint of type ’Flux tangent, (zero a-Pot)’ and

select all the outside faces (also the two circular wire in and outlets

and the conductor fix-face). Click Ok.

Solve the solution. This will take about 1 minute.

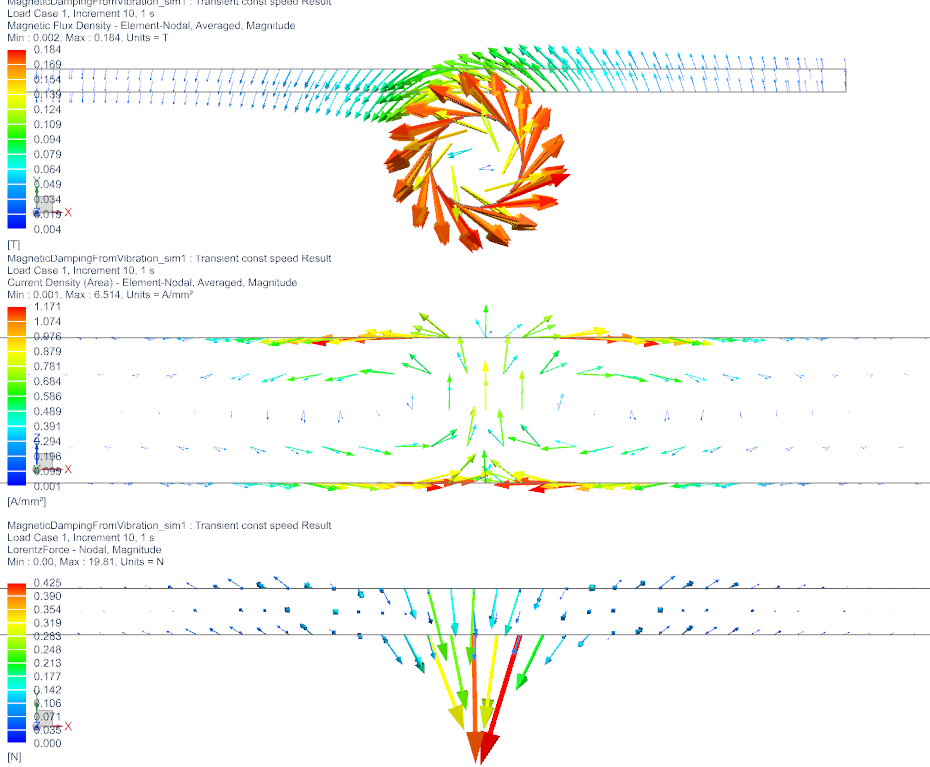

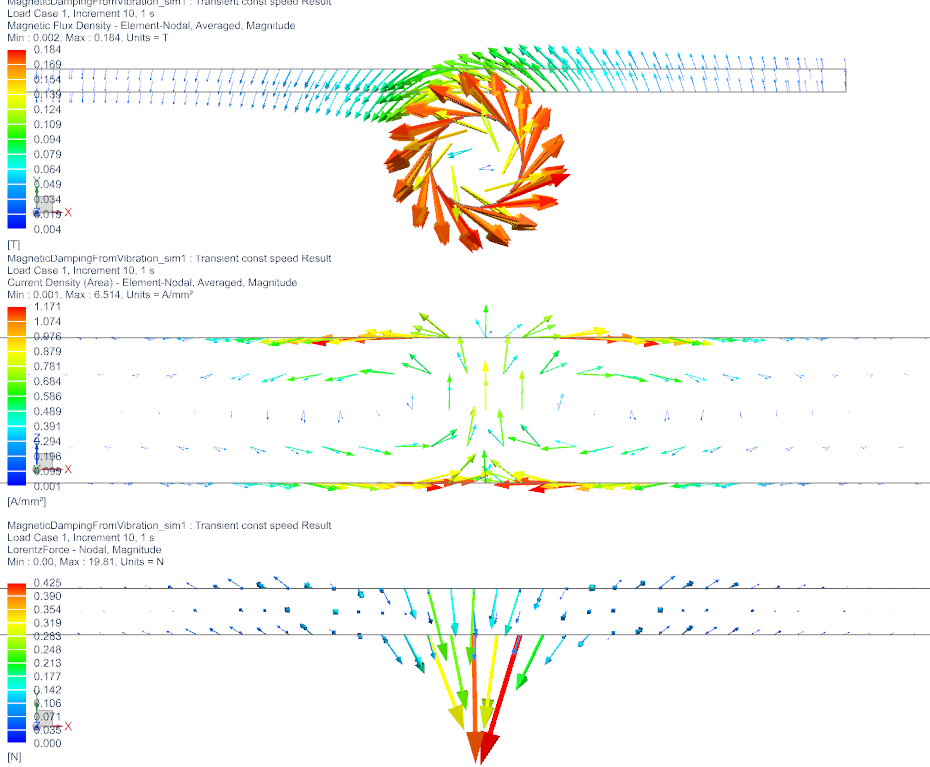

Open the results and display the ’LorentzForce’ at the last time step

in the post-view, blank all meshes but the Vibrating_Conductor

cycle through the time steps and verify that the result changes only during the first 4 time steps. After that the solution has become static.

show the force as vectors (maybe increase the arrows-size) and verify that the direction points against the velocity direction. Thus, the calculated force has a damping effect on the motion.

the picture below shows the magnetic fluxdensity (top), the

induced current (middle) and the lorentz force (bottom)

To avoid the extra time steps from the prior transient simulation we now do a frequency domain simulation. This will give the steady state result in only one step. But, as a trick, we will set the forcing frequency to nearly zero Hz. This will set the wire current to nearly static and only the velocity will contribute to the eddy current generation.

Create the solution

Click ’Solution’ and set the ’Solution Type’ to ’Magnetodynamic Frequency’

Key in as name ’Frequency const speed’

in register ’Output Requests’, box ’Plot’, activate ’Magnetic Fluxdensity’, ’Current Density’ and ’Lorentz Force (j x b)’

in register ’Frequency’, deactivate ’use Modeling Object’ and key in the ’Frequency Value’ of 0.001 Hz

Click Ok to create the solution

Create the speed:

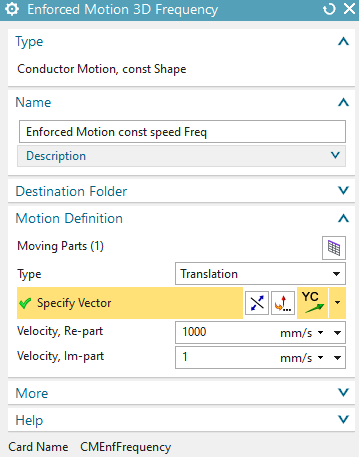

Click ’Simulation Objects’, ’New Simulation Object’, ’Enforced Motion 3D Frequency’

set the Type to ’Conductor Motion, const Shape’

key in at name ’Enforced Motion const speed Freq’

in box ’Motion Definition’, at ’Moving Parts’, click ’Create Moving Parts...’

in the next window in box ’Selection’, select the ’VibratingConductor’ and click ’Add’ (right to the box ’List’). Then click ’Close’

back in the window ’Enforced Motion 3D Frequency’, set the ’Type’ to ’Translation’ (the default)

at ’Specify Vector’ assign the YC direction

at ’Velocity, Re-part’, key in 1000 mm/s. (Im-Part will give the same magnitude results)

Click Ok to finish the motion object.

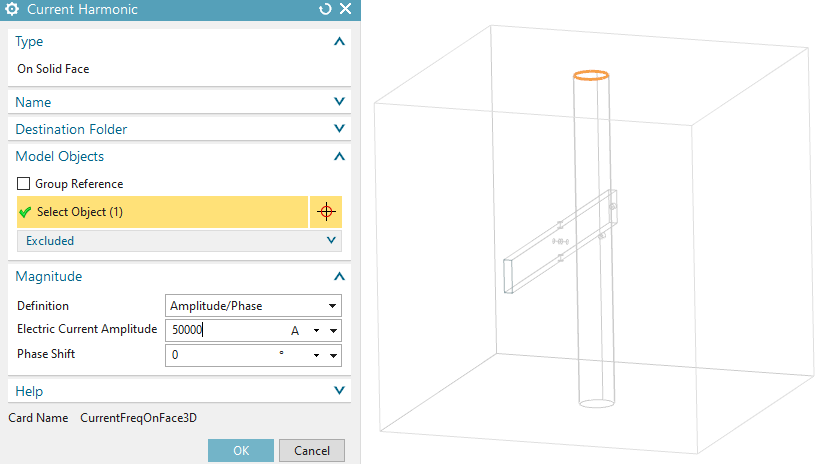

Apply constant current on the wire

create a load of type ’Current Frequency’, set the type to ’On

Solid Face’ as shown in the below picture, key in 50000 A and click

Ok.

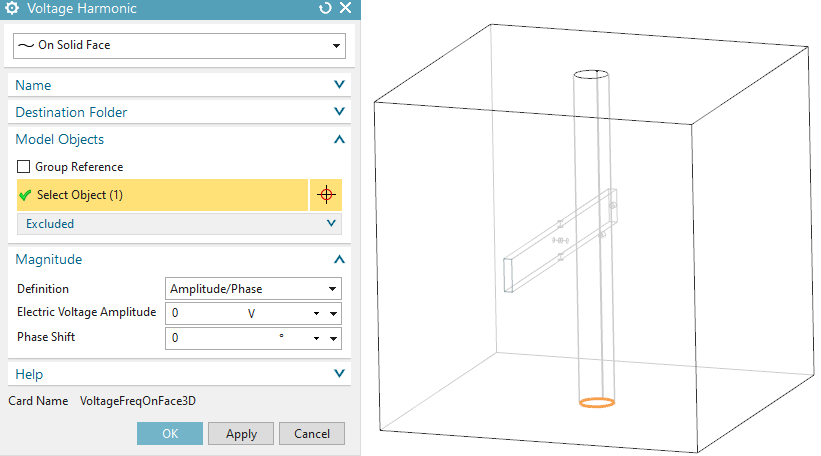

create a load of type ’Voltage Frequency’, set the type to ’On

Solid Face’ as shown in the below picture, key in 0 V and click

Ok.

Use drag and drop to reuse the existing constraint ’Flux tangent (zero a-Pot)’ into the new solution

Solve the solution. This will take only a few seconds

Open the results and display the ’LorentzForce’. Verify that it is the same result (nearly) as it was in the transient simulation.

check also the ’Current Density’ result. It is also the same as in the transient simulation.

Optionally change the forcing frequency to something higher, for instance 1 Hz, and solve again. The results now should slightly change because now there additional induction effect from the AC wire on the conductor. Don’t forget to set the frequency back to the small value.

Following, we want to apply not only constant but real vibration velocity that results from an accurate response dynamics simulation.

Set up the Fem file for Nastran

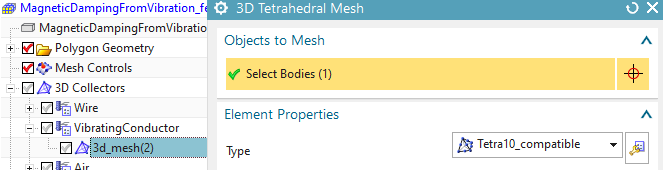

Make the Fem part the displayed

edit the mesh of the conductor and set the Type to

’Tetra10_compatible’. Click Ok

Hint: These are the high quality elements that should be used in

structural dynamics. The MAGNETICS solver can use these also, but they

will be treated in the same way as before. Instead, in MAGNETICS, the

’Shape Functions’ could be set to ’Third Order’, what would result in a

similar treatment.

in the Simulation-Navigator, use RMB on the Fem part and click ’Edit’

in box ’Solver Environment’, set the Solver to ’Simcenter Nastran’ (the first in the list). Click Ok.

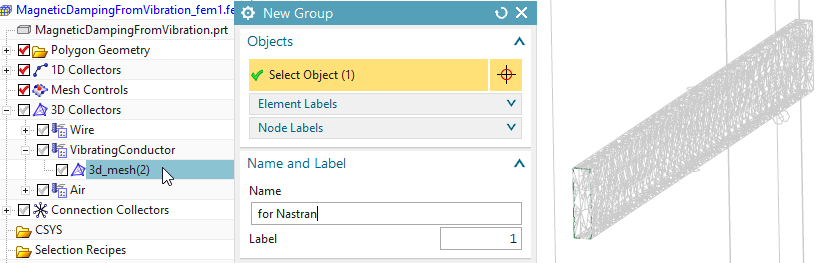

in ’Groups’, click ’New Group’ and key in the name ’for Nastran’

use the Simulation-Navigator to select the mesh of the Conductor.

Click Ok

Hint: Using this group we will tell Nastran not to use the remaining

elements (Air)

Edit the mesh collector of the ’VibratingConductor’, edit the

physical properties and choose a aluminum material from the library (for

instance use Aluminum_5086). Click Ok, Ok

Hint: The prior used ’Buit-In’ Aluminum unfortunately cannot be used

here any more.

Set up the Sim file for Nastran Dynamic Response Sol 111

Hint: Now the Fem part has both properties: Electromagnetics and Nastran. Both solvers can use it. It is not important which of the two is currently active in the Fem part.

Change the displayed part to the Sim part

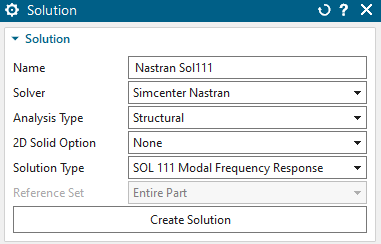

Create a new solution, set the Solver to ’Simcenter Nastran’ and the ’Solution Type’ to ’SOL 111 Modal Frequency Response’

key in the name ’Nastran Sol111’ and cklick ’Create Solution’

in register ’Case Control’, click ’Create Forcing Frequencies’,

click ’Create’ and key into the list some desired frequencies. We want

to use these: 1 Hz, 10 Hz, 50 Hz, 150 Hz, 700 Hz. Click Ok, Add,

Close

Hint: We are especially interested in the frequency 50 Hz because the

part has a natural vibration mode here.

in register ’Case Control’, edit the ’Structural Output Requests’, in ’Velocity’ click ’Enable VELOCITY Request’.

Click Ok to finish the Solution creation.

A window ’Solution Step’ appears. Simply click Ok

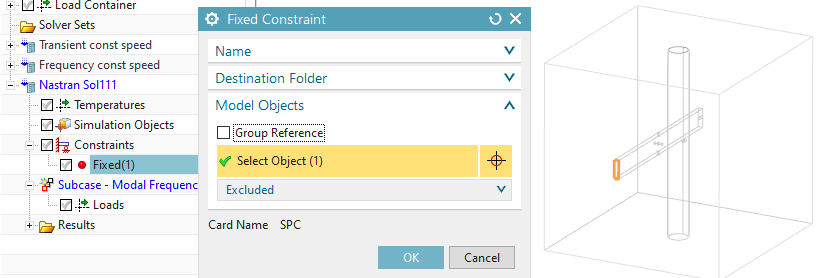

Create a fixed constraint on the face as shown in the

picture

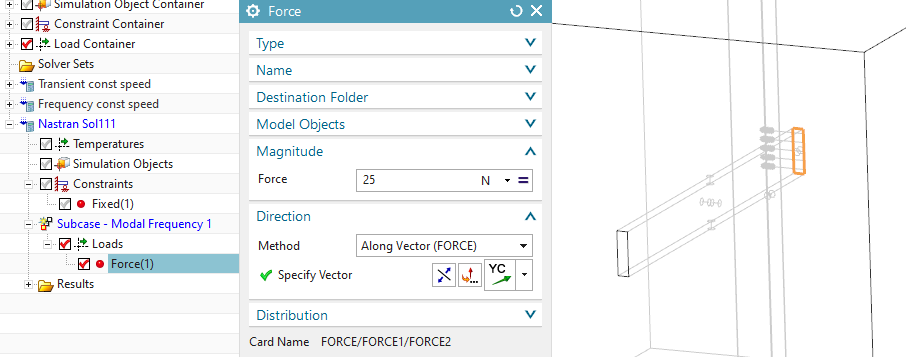

create a load of type ’Force’ with 25 N in the Y direction on the

face as shown in the below picture

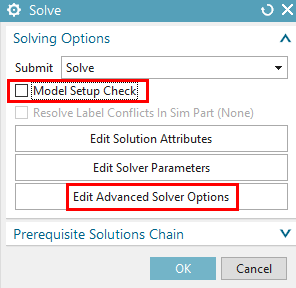

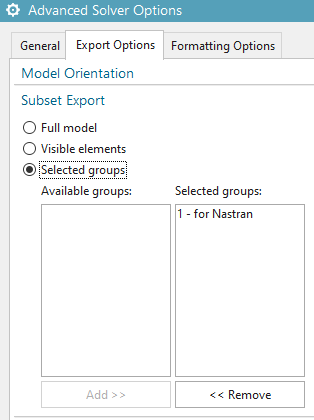

RMB on the Nastran solution, click ’Edit Advanced Solver Options’, in register ’Export Options’, in box ’Subset Export’, click ’Selected groups’ and select the previously created group ’for Nastran’, click ’Add’, Ok.

Solve the Nastran solution. Deactivate the ’Model Setup Check’

because this does not work together with the ’Subset Export’.

Open the Nastran results and display the Velocity at 50 Hz

use ’Edit Post View’, register ’Result’, set ’Complex Options’ to ’Real’. Verify that there is a zero result (picture below, left).

set the ’Complex Options’ to ’Imaginary’.

Hint: Now there is a non-zero result shown (picture below, right). The

maximum velocity is about 65 mm/s, smaller than what we have assumed in

the first simulation. This must be transferred to the magnetics

solution.

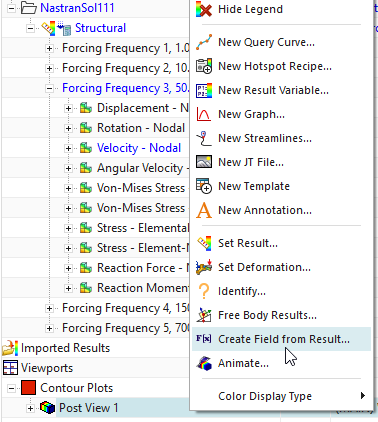

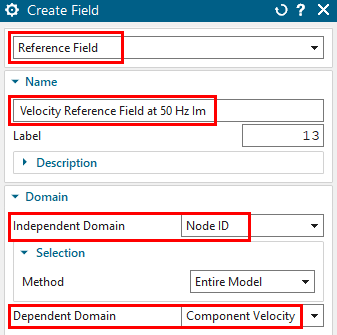

RMB on the Post-View, click ’Create Field From Result’

set the type to ’Reference Field’ (the usual also would work), key in the name ’Velocity Reference Field at 50 Hz Im’

set the ’Independent Domain’ to ’Node ID’ and the ’Dependent Domain’ to ’Component Velocity’ (see picture above, right). Click Ok

repeat the last two items also for the Real part of the velocity result. Even if this is zero, we must import it into the following solution. Name it ’Velocity Reference Field 50Hz Re’

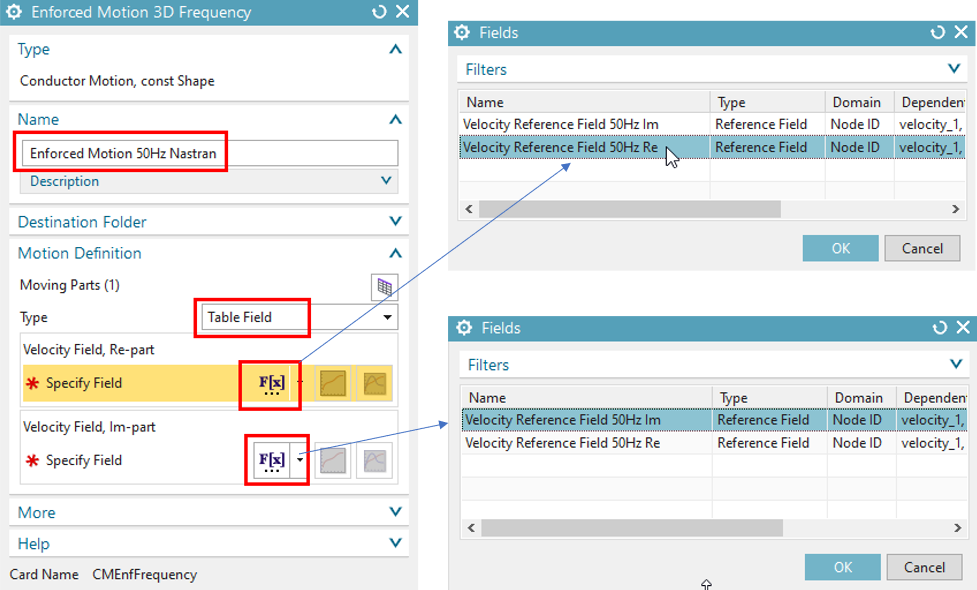

Clone the solution ’Frequency const speed’ and rename the new one to ’Frequency 50Hz with Nastran PreSolution’

Clone also the motion object ’Enforced Motion const speed Freq’ (or create a new one) and rename the new to ’Enforced Motion 50Hz Nastran’. Apply the new motion object into the new solution and remove the old one from it.

Edit the new motion object, set the Type to ’Table Field’

at ’Velocity Field, Re-part’, click ’Select Existing Field from List’ and select the field ’Velocity Reference Field 50Hz Re’

repeat the same for the Im-part. Click Ok.

Solve the solution

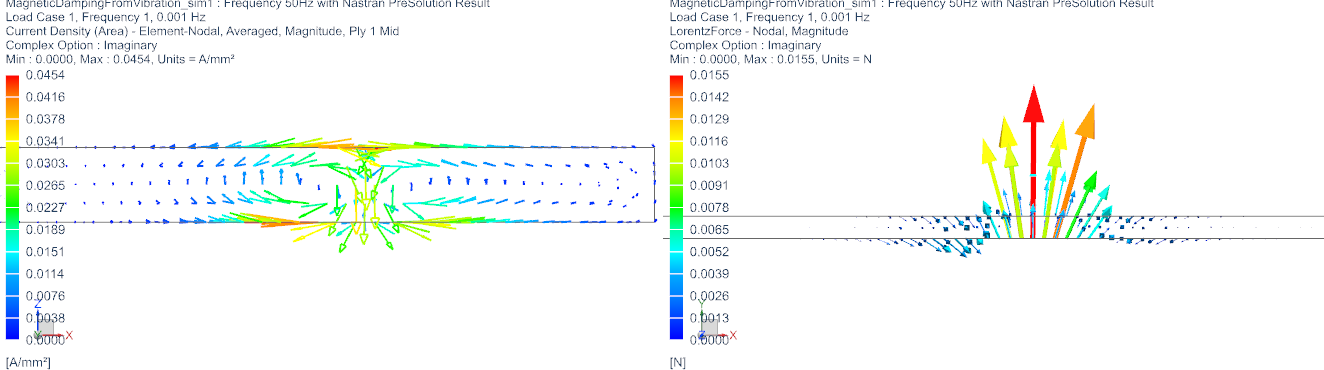

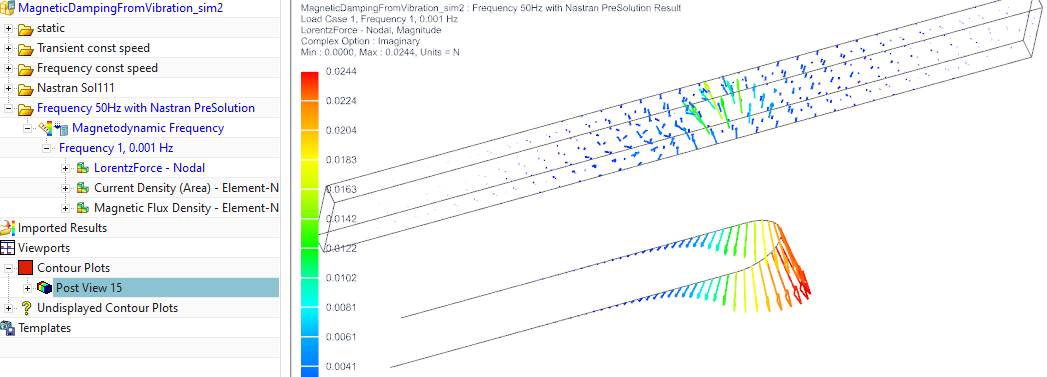

Display the resulting Current Density and Lorentz forces again

(see below picture). Both are smaller that in the first simulation

because of the small velocity. The direction has flipped because also

the velocity direction has flipped.

This chapter is optional. It shows how vibrating 1D lines can be

handled additionally to the 3D solid. We start from an already completed

model.

Open the part file ’MagneticDampingFromVibration_sim2.sim’

Notice, all solutions are same as in the prior model. The Fem file contains now additionally 1D line elements having 30 mm diameter. These behave, in a very coarse way, similar to the solid conductor. In all solutions, motion features loads and constraints such line elements are now included.

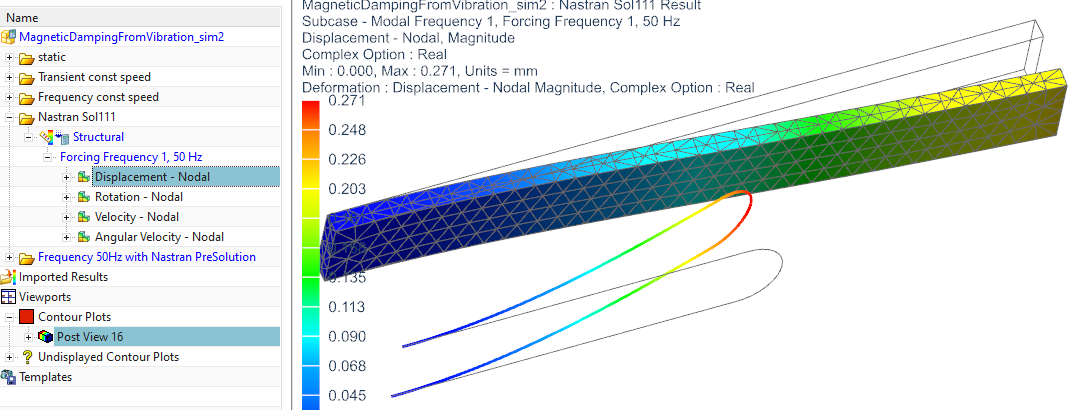

Solve the Nastran solution and display the displacement result

(see picture below. Complex option in register ’Result’ and

’Deformation’ are set to ’Real’). Notice that the line geometry vibrates

similar as the solid but in opposing direction.

Hint: The re and im-part of these velocities are already in

corresponding fields, as was demonstrated in the before chapter.

Solve the last solution ’Frequency 50Hz with Nastran PreSolution’

and display the force results as in the picture below. From the arrows

we can see, they act against the velocity or displacement.

Thus, it is possible to also use 1D-lines for calculating conductor damping from mechanical vibrations.

The tutorial is finished.

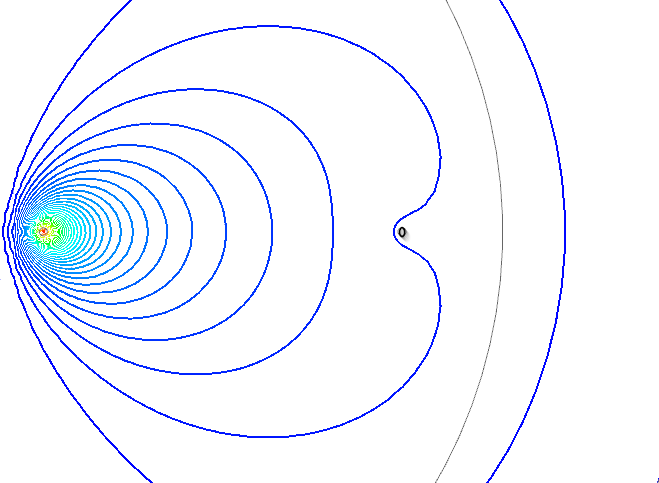

In this tutorial, we will use the Magnetics solver to calculate the

self-inductance and mutual inductance of two circular and closed coils

in a 2D axisymmetric model. The below picture shows these two coils in a

axisymmetric section and their magnetic fieldlines.

The calculation of mutual inductance is important for many practical

applications.

For example:

Transformers: In transformers, mutual inductance enables energy transfer between the primary and secondary coils. Calculating the mutual inductance helps optimize the efficiency, performance, and output voltage of the transformer.

Wireless Power Transfer: In wireless charging

systems, energy transfer relies on magnetic coupling between coils.

Calculating mutual inductance ensures optimal coupling and maximizes the

efficiency of power transfer between the coils.

In both examples you want to achieve a high mutual inductance to

maximize the power transfer between the coils. A small mutual inductance

is often necessary in small circuits to prevent circuits or nearby wires

from interfering with each other

Definition of the inductivities: Although induced currents exist only in AC, it is still possible to evaluate the inductance for this case from a DC analysis. Self-inductance \(L_{11}\) and mutual inductance \(L_{12}\) are defined as the total magnetic fluxdensity B passing through a surface, whose faces define the primary and secondary coils. These can be expressed as:

\[L_{11} = \frac{\int_{S_1} \mathbf{B} \cdot \mathbf{n}dS}{I_1}\]

\[L_{12} = \frac{\int_{S_2} \mathbf{B}

\cdot \mathbf{n}S}{I_1}\]

where \(I_1\) is the current passing

through the primary coil, \(\mathbf{n}\) is the vector normal to the

surface, and the integrals are taken over the surfaces \(S_1\) and \(S_2\) defined by the primary and secondary

coils.

Download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.10MutualInductance.zip

Unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter ![]() (or

NX). Use Version 12 or preferably newer.

(or

NX). Use Version 12 or preferably newer.

In Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’MutualInductance.prt’ and click OK. (Maybe you must set the

file filter to ’prt’)

and navigate to folder ’start’. Select

the file ’MutualInductance.prt’ and click OK. (Maybe you must set the

file filter to ’prt’)

Start the application Pre/Post.

Create a New Fem and Sim. Set the solver to ’MAGNETICS’ and Analysis Type ’2D or axisym Electromagnetics’. Click OK.

If a new window appears asking for the solution type, click ’Close’. We want to create the solution later.

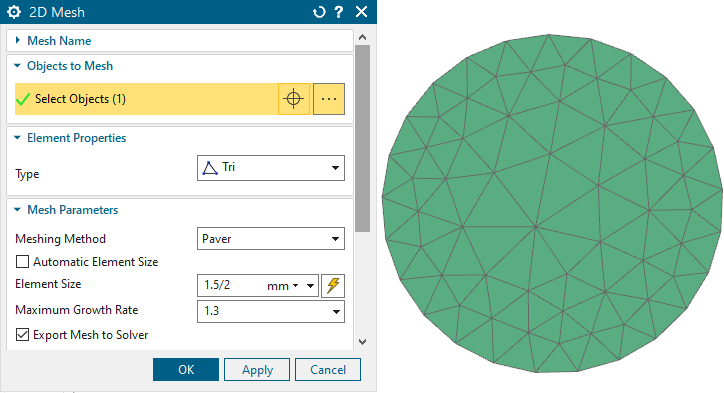

Start by meshing the the inner coil. Click ’2D Elements’, for

’Type’ use ’tri’. Select the inner coil and use half of the recommended

element size.

Edit the mesh collector, change the name to ’Coil_Inner’. Click

’Edit’ and select ’Copper simple’ from the material library.

Create a second mesh for the outer coil. Select the outer coil and apply the same settings as used for the inner coil. For material, edit the mesh collector and choose ’Copper simple’.

Next, create a mesh for the air. Again, use ’2D Mesh’ with the recommended element size divided by 2. Edit the mesh collector, choose ’FluidPhysical’ and ’air’ as material.

The last mesh ist the infinity air. Click ’2D Mesh’, select the infinity air and use half of the recommended element size.

In the mesh collector choose ’Infinity2D’ and click ’Create’. Set

the settings as shown in the window below.

Since mutual inductance can be calculated in both DC and AC scenarios, we will compute two separate solutions and compare them.

Create a solution of type ’Magnetostatic’

In ’Output Requests’, ’Plot’ activate ’Magnetic Fluxdensity’,

’MagneticPotential (a-Pot)’, ’Magnetic Fieldstrength’ and ’Current

Density’. In ’Table’ activate ’Electrode Voltage’ and ’Fluxlinkage -

Vectorpotential on Conductors’.

Hint: The desired mutual and self inductance results from the last

output request.

In ’2D’ active the ’axisymmetric’ checkbox.

Next, create a constrait of type ’Flux tangent (zero a-Pot).

Select all 4 outside lines.

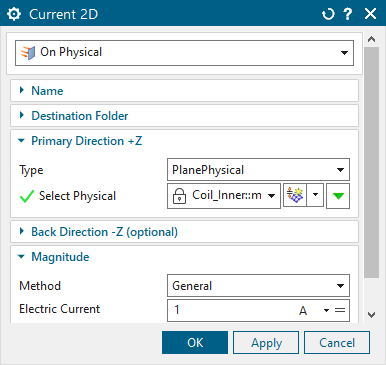

Now, create the loads. Click ’New Load’, ’Current 2D’. Accept

type ’On Physical’, and select ’Coil_Inner’ from the selection list. In

’Electric Current’ type ’1’A. Then create a second load of type ’Voltage

2D’ for the second coil. Select ’Outer_Coil’ and type ’0’V in ’Electric

Voltage’.

Before solving, right click on the solution and click ’Edit Solution Parameters...’. Under ’General’, ’Result Graphs (afu)’, change to ’Create, keep txt File’.

Now, solve the solution.

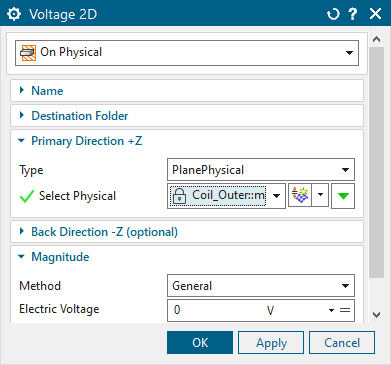

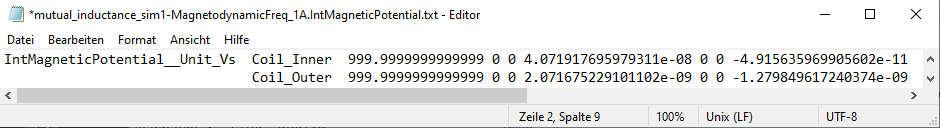

Open the ’IntMagneticPotential.txt’ file in your work folder. Here we can see the mutual inductances of the coils. We will compare this value with the AC values later on.

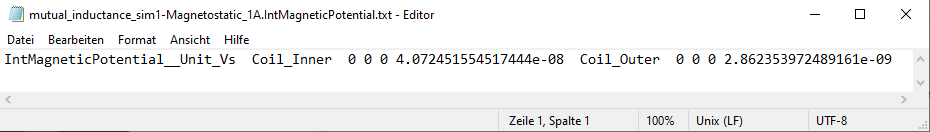

Next, we will simulate the mutual inductance in AC.

Create a new solution of type ’Magnetodynamic Frequency’. In ’Output Requests’, ’Plot’ activate ’Magnetic Fluxdensity’, ’Magnetic Fieldstrength’, ’MagneticPotential (a-Pot)’, and ’Current Density’. In ’Table’, activate ’Electrode Voltage’ and ’Fluxlinkage - Vectorpotential on Conductors’.

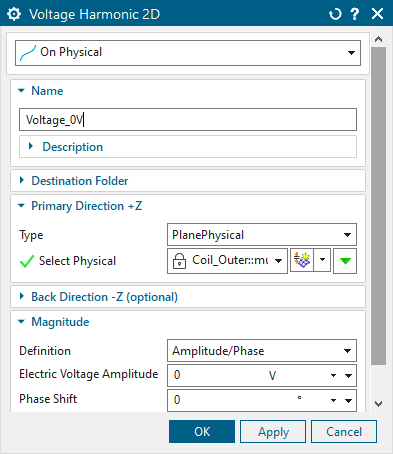

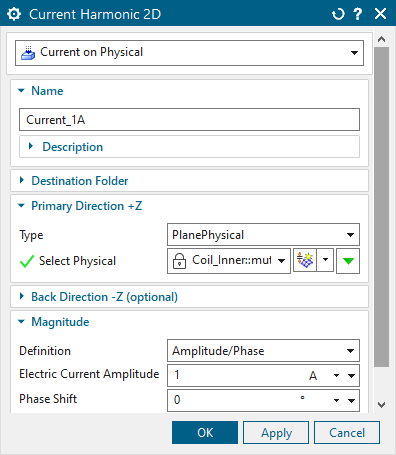

Create the loads: Click ’New Load’, ’Current Harmonic 2D’. Accept ’On Physical’ and select the inner coil. For ’Electric Current Amplitude’ type ’1’A and ’0’ phase shift.

For the second coil create a second load of type ’Voltage

Harmonic 2D’ and select the outer coil. Type ’0’V for ’Electric Voltage

Amplitude’.

Drag and drop the constaint from the first solution in the new soluten. Edit the solution solver parameters and change to ’Create, keep txt File’.

Then solve the solution.

Again, open the ’IntMagneticPotential.txt’ file in your work

folder. The first value is the frequency, then the mutual inductance

(realpart and imaginarypart) of the coils follow. Since the load is

applied on the inner coil, the calculated inductance for the inner coil

is the self inductance (See formula for \(L_{11}\) above). Current is induced on the

outer coil, so the mutual inductance is 2.071 nH - j 1.28 nH.

The real part of the mutual inductance represents the effective coupling between the coils, while the imaginary part is related to losses such as eddy currents, resistive effects, or phase shifts between the coils due to reactive components.

The mutual inductance of the DC solution was 2.862 nH while the AC amplitude value is 2.435 nH. Thus, the deviation is 15%.

To conclude, a simulation for mutual inductance can be solved in both AC or DC. The AC solution contains losses and therefore is more accurate.

The tutorial is finished.

In this tutorial we show how to create a Resonant Circuit in a 1D

Simulation. We calculate the circuit current over time and verify the

result with a analytic calculation. Later we replace the 1D resistance

with a 3D geometry. This concept can be used to connect realistic 3D

geometries with 1D circuits.

Start the program Simcenter 3D or NX. Use version 12 or preferably newer.

In Simcenter, create a new file. Key in for name ’ResonantCircuit1D’ and click OK.

From toolbar Application click on ’Pre/Post’ ![]()

Click in toolbar ’Magnetics’ on ’New FEM and Simulation

(Non-Manifold)’ ![]()

Create a Solution with type ’Magnetodynamic Frequency’. In ’Output Request’, ’Plot’, activate ’Electric Potential (phi-Pot). In ’Table’, activate ’Circuit Voltage’ and ’Circuit Current’. As Frequency use 50Hz.

In ’Edit Solver Parameters’, select ’Create, keep txt Files’.

Click ’Node Create’ from toolbar ’Nodes and Elements’. Create 4 nodes, approximatly in form of a rectangle. Use any positions.

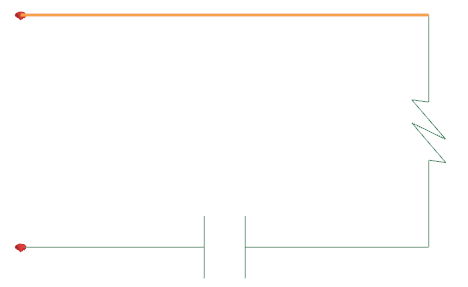

Create a ’1D Connection’ and select with ’Node to Node’ the first two nodes. Set the type to ’Resistor’. Create a second 1D Connection, select the next two nodes with type ’Inductor’. Create between the last two nodes another 1D Connection with type ’Conductor’.

Edit the physicals of the resistor. Key in \(1\Omega\) for ’Electric Resistance per Element’. Do the same for the ’Inductor’ with 1H and 1(Farad) for the ’Capacitance’ of the ’Capacitor’.

Switch to the Sim File and click ’Load Type’, ’Voltage Harmonic’. Switch to ’On Circuit’ and select the two open nodes as primary and secondary node. Key in 1V.

Solve the Solution.

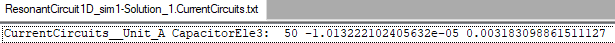

Open the file with the extension ’.CurrentCircuit.txt’.

Shown is the real and imaginary part of the circuit current at every

component. Since we have a serial circuit, the current is always the

same.

We set up a differential equation of the ’Serial Resonant Circuit’ to

calculate the current over the time t. The differential equation results

from the sum of the circuit voltages: \[U(t)

= U_{R} + U_{L} + U_{C}\] \[U(t) = R

\cdot I(t)+ L \cdot I^{'}(t) + \frac{1}{C} \cdot \int_{}^{}I(t)

dt\] We derive the equation by time to avoid the calculation with

an integral. \[U^{'}(t) = R \cdot

I^{'}(t)+ L \cdot I^{''}(t) + \frac{1}{C} \cdot

I(t)\] with \(R = 1\Omega\),

\(L = 1H\), \(C = 1F\) and \(U(t) = cos(2 \cdot \pi \cdot 50Hz \cdot

t)\), so \(U^{'}(t) = 100\pi \cdot

cos(100\pi \cdot t)\).

We use the following mathematical approach: \[I_{p}(t) = D_{0} \cdot sin(bt) + E_{0} \cdot

cos(bt)\] That approach and it’s derivations are inserted into

the differential equation and after some simplifcations we get:

\(cos(b \cdot t) \cdot b + (sin(b \cdot t)

\cdot 0) = cos(b t) \cdot (D_{0} \cdot b - E_{0} \cdot b^{2} + E_{0}) +

sin(bt)\cdot(-E_{0} \cdot b - D_{0} \cdot b^{2} + D_{0})\)

with \(b = 100\pi\) and a coefficient

comparision two equations with two variables result.

Solving the equation system gives \[D_{0} =

1.013 \cdot 10^{-5}, E_{0} = -3.18 \cdot 10^{-3}\] We lead this

back to our approach and get a equation describing two oscillations:

\[I(t) = 1.013 \cdot 10^{-5} \cdot

sin(100\pi \cdot t) - (-3.18 \cdot 10^{-3}) \cdot cos(100\pi \cdot

t)\]

The sum of the two oscillations finally results in \[I(t) = 3.18A \cdot 10^{-3} \cdot sin(100\pi \cdot

t - 1.571)\] Converting this into a complex number gives \(I = 1.013 \cdot 10^{-5} -j3.18 \cdot

10^{-3}\). This is the settled result for the current behavior

over time and matches precisely with the result of the simulation.

We now replace the 1D Resistor with a 3D geometry. Because of the

material properties and the geometry, there arises a resistance.

Following we open an existing model and walk through some interesting

features.

Download the model for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.8ResonantCircuit.zip

Extract the zip-archive. In Simcenter, click Open ![]() and

navigate to the folder of the extracted archive. Select the file

’ResonantCircuit3D_sim1.sim’ and click OK.

and

navigate to the folder of the extracted archive. Select the file

’ResonantCircuit3D_sim1.sim’ and click OK.

The meshes for the air and the resistor are already created. We use a self made material for the resistor and get a resistance of \(1.07\Omega\) which nearly corresponds to the prior 1D simulation.(\(1.0\Omega\))

There are two 2D meshes of type ’ElectrodePhysical’. These are

necessary to connect a 1D connection to a 3D geometry. They don’t

contain any physical properties.

To finally connect the 2D electrode with the outside circuit we

need a 1D connection of type ’Connector’. Such a connector must be

between a node of the electrode and another node in the circuit. See

picture below.

Switch to the Sim File and solve the solution.

Open the file with the extension ’.CircuitCurrent.txt’

Shown is the circuit current, which matches well with the 1D simulation. The small deviation results from the slight difference in the ohm resistance.

The tutorial is finished.

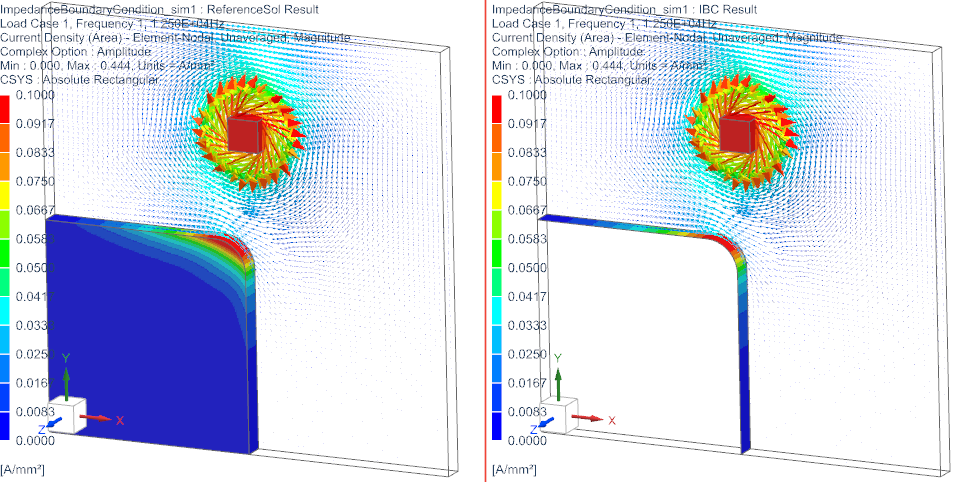

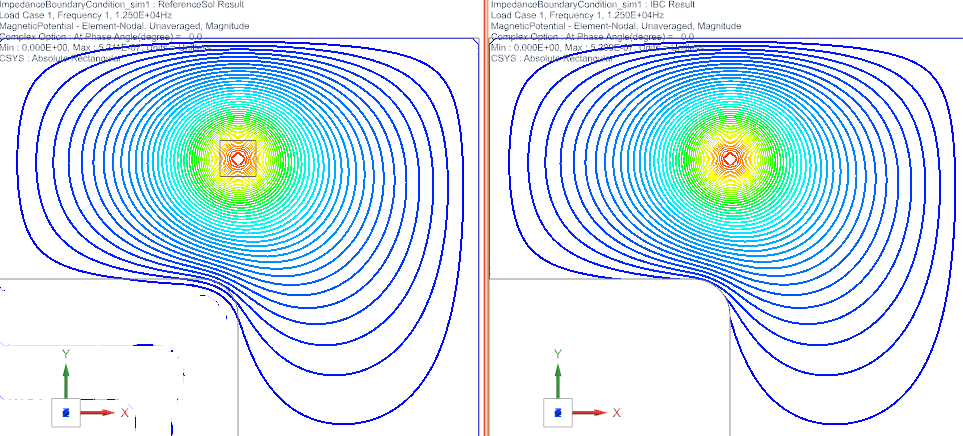

This tutorial introduces you to the ’Finite Conductivity Boundary’,

also called ’Impedance Boundary Condition’ (IBC). The IBC is a powerful

tool for defining boundary conditions on conductive or magnetic surfaces

without the need to model their internal structure in detail. This

approach is particularly beneficial in high-frequency applications, such

as RF systems or eddy current simulations.

The image on the top left illustrates an AC electric conductor,

surrounded by overlay arrows that represent the rotating magnetic field

it generates. Nearby, a 3D conductor block demonstrates the eddy

currents induced by this field. On the right side, the same setup is

shown, but with a key difference: the conductor block is modeled as a

thin shell using the Impedance Boundary Condition. Remarkably, the eddy

currents on this modeled skin closely resemble those within the full 3D

conductor. This highlights the effectiveness and purpose of the

Impedance Boundary Condition. The below picture shows the same but with

field lines.

The model files can be opened in NX/Simcenter version 2306 or later.

Download and extract the model for this tutorial from the

following link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.9ImpedanceBC.zip

In Simcenter, open from ’complete’ folder the file ’ImpedanceBoundaryCondition_sim1.sim’.

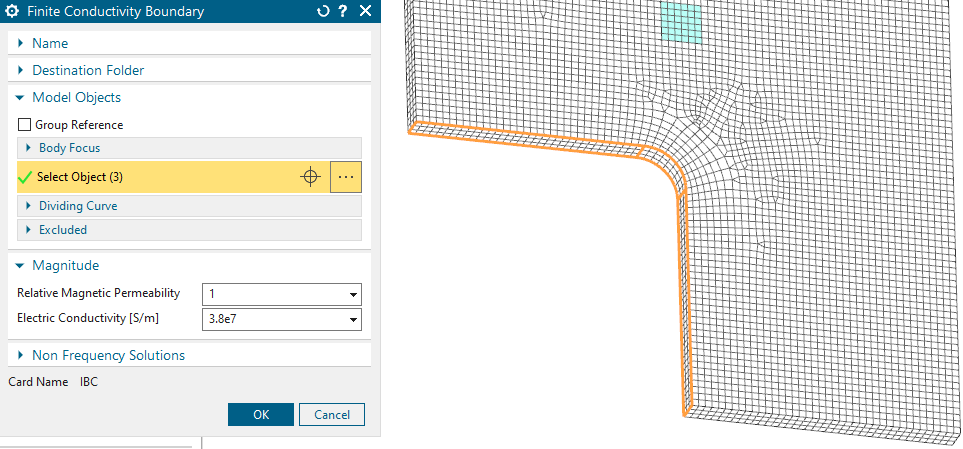

There is a reference solution using the 3D conductor block and a second solution called ’IBC’ which uses a ’Deactivation Set’ to exclude the 3D conductor.

the ’IBC’ instead uses a constraint ’Finite Conductivity

Boundary’ (IBC). In the feature menu (shown below), you can specify the

electrical conductivity and permeability for the geometry that was

replaced.

The tutorial is finished.

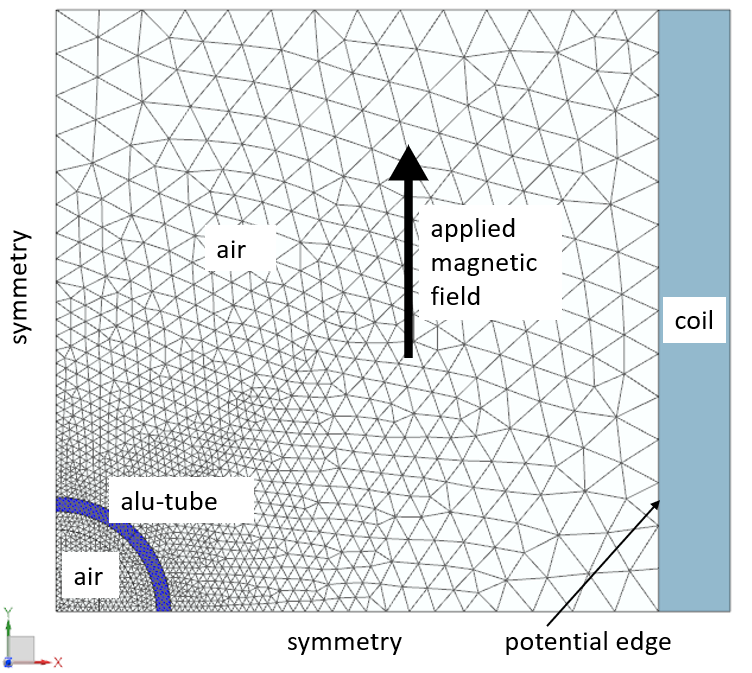

In this example an aluminum tube (depicted blue in the figure) will

be considered that is loaded by a time dependent magnetic field in

vertical direction. We will compute the time dependent induced current

(eddy current) within the tube. Such eddy current losses can then be

used to calculate temperatures on the tube (not shown in this tutorial).

Reference results are available from the TEAM benchmark. Additionally,

the reader may also read the attached document for the TEAM 1a task to

find further information.

According to the TEAM 1a description, the applied magnetic field

strength in the y direction decays exponentially with time as \[B_{y} = B_{0} \space e^{\frac{-t}{\tau}}\]

where \(B_{0} = 0.1 T\) and \(\tau = 0.0397\).

For this example we will apply the demanded magnetic field in two

different ways: first, we will apply said field via a difference of a

magnetic potential on the two opposing boundaries; and second, we will

apply an electric current on the coil face. In both cases the result

shall be very similar. In order to start from a steady state solution we

will first analyse for statics and then restart from this solution.

Estimated time for this example: 0.5 h

Exercises are:

Analysis of Eddy Currents, conductive and hysteresis Losses,

Symmetry constraints,

Applying given potentials as math function,

Using a steady state solution as initial condition.

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.1Team1a.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter 3D or NX. Use Version 12 or preferably newer.

In Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’Team1a.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

and navigate to folder ’start’. Select

the file ’Team1a.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

Start application Pre/Post and create a ’New Fem and Sim’ File.

Set off the creation of an Idealized Part.

Choose the Solver ’MAGNETICS’, ’2D or axisym Electromagnetics’.

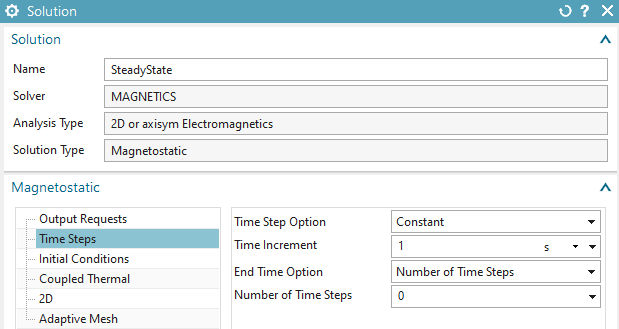

Create a Solution of type ’Magnetostatic’.

Hint: This will be the steady state solution that we will later use to

restart from.

Name the solution ’SteadyState’.

In register ’Time Steps’, accept the defaults ’Number of Time

Steps’ as 0 as well as ’Time Increment’ as 1.

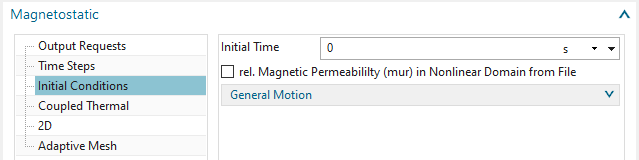

In register ’Initial Conditions’, accept the defaults, i.e.

’Initial Time’ to 0 s.

Hint: A second solution will restart from this first solution.

Therefore, we want the second solution to start at time 0; meaning that

we have to use zero time for this first solution.

Accept all other default settings.

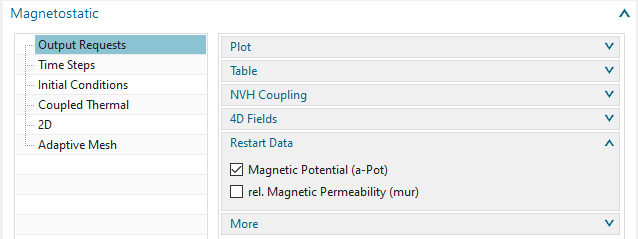

Edit the output requests of this solution. In box ’Restart Data’,

activate ’Magnetic Potential (a-Pot)’.

Hint: This setting is necessary to use this solution later to restart

from.

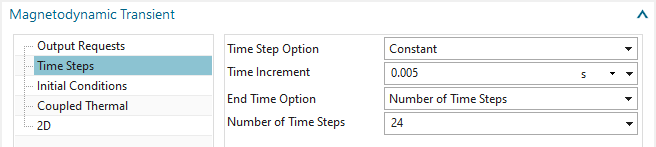

Create a second solution of type ’Magnetodynamic Transient’. Name

it ’MagDynTran’. Hint: This will be the main solution

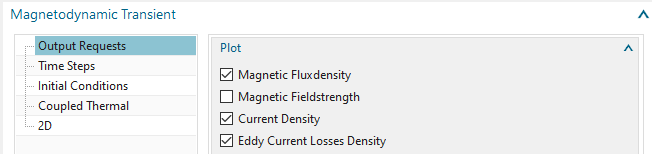

Activate the following Output Requests in register ’Plot’:

’Current Density’: To compute the induced eddy currents and display them as a contour plot.

’Eddy Current Losses Density’: To compute the losses \(P_{c}\) that result from electric resistance and eddy currents \(I\) corresponding to \(P_{c} = R I^{2}\) with R as ohm resistance. This approach for losses analysis is valid typically in massive conductors where hysteresis effects are neglectable.

And in register Table:

’Eddy Current Losses’: To compute the losses \(P_{c} = R I^{2}\) integrated over geometry

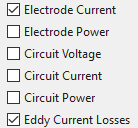

Set the ’Time Steps’ settings as in the next picture

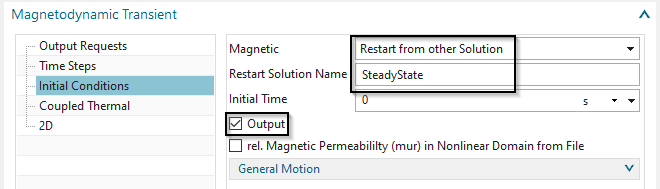

In register ’Initial Conditions’: Set the option

’Magnetic/Temperature’ to ’Restart from other Solution’. Key in the name

of the already created solution into the field ’Restart Solution Name’.

Also activate ’Output’ to enable the system to write the results for the

initial condition to the result file. This is for checking only.

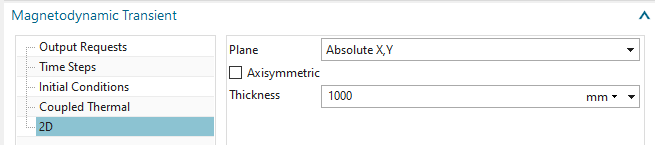

Accept the defaults in register ’2D’. Ok.

To avoid a sharp step of eddy currents that would appear at the

beginning: In solver parameters under ’Numeric’, set the option ’Shape

Functions, Electromagnetic’ to ’First Order’.

Optionally step: This problem can also be solved in frequency

domain. The excitation has a frequency of about 4 Hz. So, if desired,

create another 2D solution of type ’Magnetodynamic Frequency’. Name the

solution ’MagDynFreq’ and set the forcing frequency to 4 Hz. Constraints

and loads can be made very similar to the transient one for this

solution.

Switch to the Fem file.

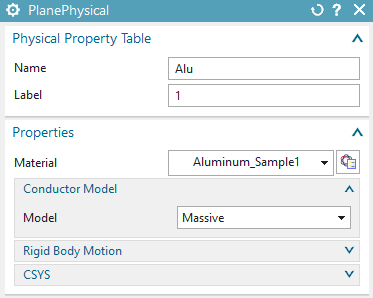

Create a tri mesh on the faces of the aluminum tube. Use the suggested mesh size value divided by 2. The system automatically creates a ’PlanePhysical’ which you can modify now.

Assign material ’Aluminum_Sample1’ from the library

’Magnetics_Materials.xml’. Name the Physical and mesh collector

’Alu’.

Create a tri mesh on the other faces (see picture, use suggested

element size /2) for the air. Assign a physical of type ’FluidPhysical’

and ’Air’ as material.

Hint: Do NOT mesh the coil face. This will be used later. For this part

of the tutorial the coil face stays unmeshed.

For easier post processing, click on the button ’Rename Meshes

...’ ![]() from the Magnetics toolbar. That

utility renames all meshes and therefore is a useful feature especially

with larger models and many meshes.

from the Magnetics toolbar. That

utility renames all meshes and therefore is a useful feature especially

with larger models and many meshes.

Switch to the Sim file.

Create a first constraint of type ’Flux tangent (zero a-Pot)’ for

the symmetry at plane x=0.

At plane Y=0 (and at the top edge) we need normal flux lines. So

create a constraint of type ’Flux normal (free a-Pot)’ on these 6

edges.

Background: These two conditions define the symmetric situation. Notice

that the normal condition could also be left, because normal flux lines

is the default behaviour of this magnetic vectorpotential formulation at

boundaries.

Define a time dependent flux density in the air.

Background: The task-description of TEAM 1a demands an exponential varying magnetic flux density with time. We create this flux density by using a given potential on the boundary edge. We use the trick that any magnetic potential difference between two positions results in magnetic flux through the area between the two positions. This constraint leads to an equally distributed flux density in a homogeneous area. Only the aluminum-tube will disturb the homogeneous flux density. And this disturbing effect shall be analysed.

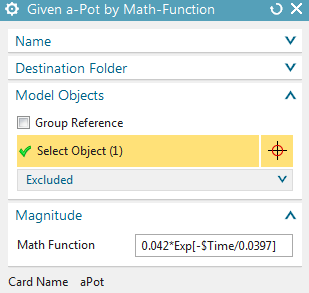

Create a constraint of type ’Given a-Pot by Math-Function’ on the

right edge. Key in the displayed formula into the field ’Math Function’.

Click OK.

Hints: The factor 0.042 results from the requirement that at the beginning of the time period a constant flux density of 0.1 T shall exist. This value was computed by a pre analysis without aluminum-tube. The syntax for this formula and further possibilities are described in the Getdp-documentation.

Create a zero voltage load with type ’On Physical’ on the alu

tube. This is necessary to fix the z direction degree of freedom for the

electric current in this conductor. Such a condition must always exist

on electric conductors in dynamic simulations. In case the optional

frequency solution is there, this voltage load must be created for this

solution additionally.

Put all constraints and the load into all solutions. The

solutions, two or three - depending on the optional frequency solution -

in the navigator should look like in the picture.

First solve the ’SteadyState’ solution. Then solve solution ’MagDynTran’ that restarts from the previous one.

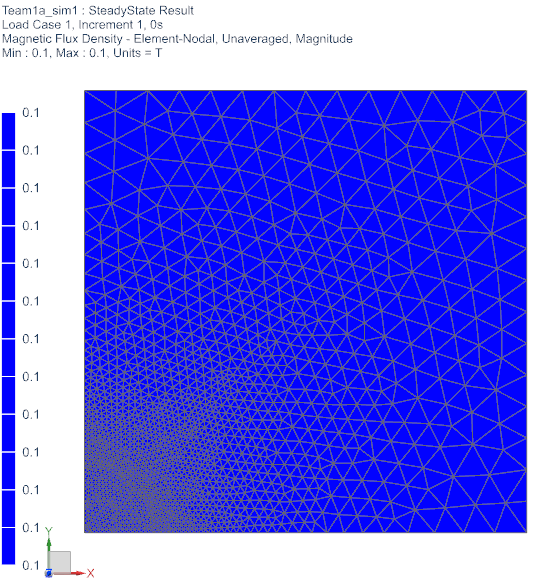

Check the SteadyState result:

Check that at the beginning of the time period flux density is

exactly 0.1 Tesla in the whole area. The directions are all

vertically.

Then check the transient result:

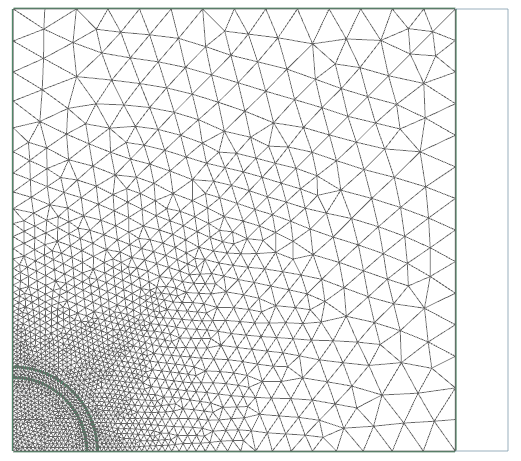

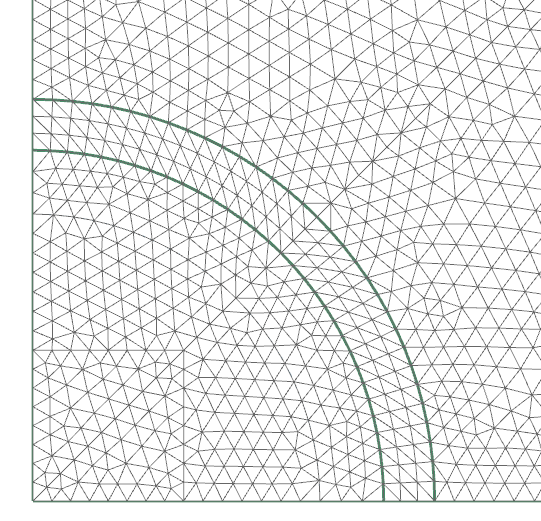

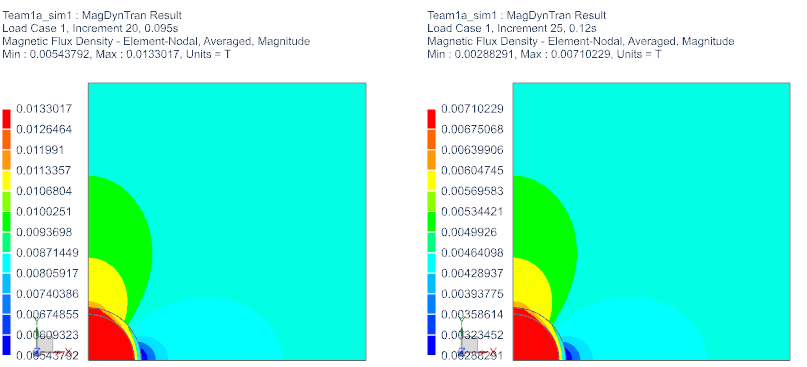

Check how magnetic flux density varies with time. The following

pictures show magnetic flux density at the beginning, in the middle and

at the end of the time period.

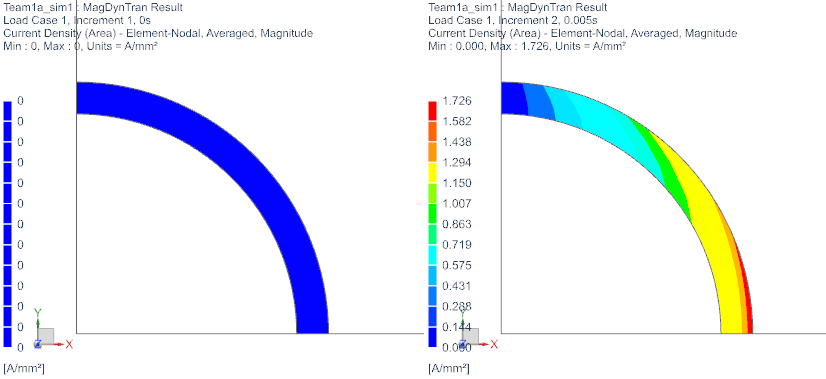

Check the induced current density in the aluminum-tube at

increments 1, 2, 5 and 25.

In the following picture, we see two different graphs which plot

the current in the Alu over time. The graphs in the left picture result

from several benchmark teams using different numerical codes, whereas

the right one shows the simulated solution in our code NX-Magnetics.

Since the left approaches are all centered around our simulation, we can

say that our simulation has a derivation of about 10%.

As an alternative to the first part of the example we want to realize the flux density condition now by giving a time dependent current on the right face. The resulting magnetic field leads to the same flux density.

Open the previously created Sim file.

Clone all solutions (2 or 3, in case the frequency solution is

also there). Rename the new ones with extension ’_coil’.

in the transient one, change the ’Initial Condition - Restart Solution Name’ to the new one: ’SteadyState_coil’.

Change to the Fem part and mesh the face right in the picture.

Assign material copper and stranded properties with 1 turn. Using this

stranded method you will get a homogeneous distribution of the current

over the face.

Change to the Sim file and

In all new solutions (_coil), remove the previously used potential constraint.

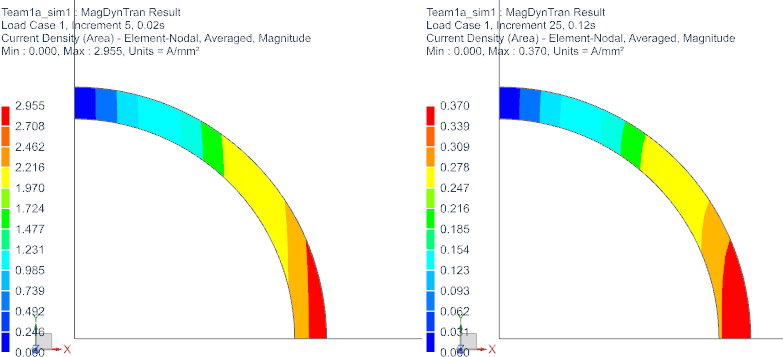

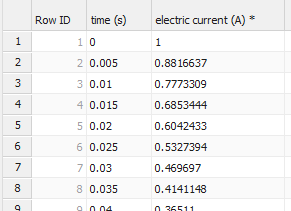

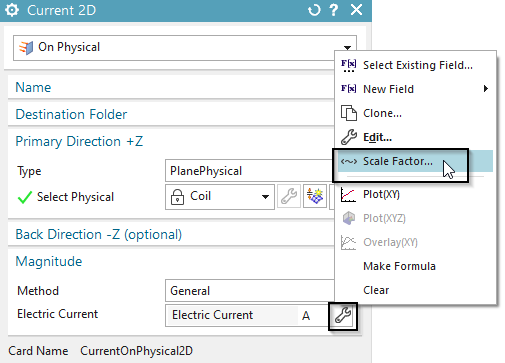

Create a load of type ’Current 2D’, with type ’On Physical’.

Accept the default method ’General’.

Select the newly created physical ’Coil’.

Click the ’equal’ button ![]() and select the table function as shown

in next picture.

and select the table function as shown

in next picture.

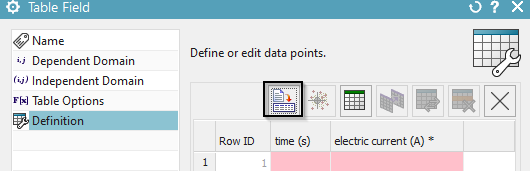

In following dialogue ’Table Field’ click 4 times ’Next’ to

accept some defaults. Then, click ’Import from File’ and select the file

’time_function.csv’ from the ’start’ folder, that already contains data

points for the exponential function. OK.

All the points are transferred into the dialogue. Click OK.

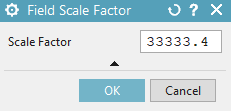

Back in the prior dialogue, insert a scale factor of 33333.4 to

the field by simply adding it to the formula as shown:

Add this new load to both solutions.

For the optional frequency solution, such a tabular definition is not possible. Instead, a fixed value current load with 1 A can be created.

Solve the two (or three) solutions in the same order as before.

Post-processing.

All results should be very near to those we have analysed in part one of

this exercise. (Blank the copper mesh in the post view to compare the

results to the first exercise.)

The tutorial is complete. Save your parts and close them.

In this example there is a network defined connecting different

electrodes of several conductors. The conductors are of 3D, 2D and 1D

type. The example shows how to set up these features. A harmonic current

load is applied on the left and right points of the network (see

picture). So the electric current flows through all conductors.

Download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.5Network.zip

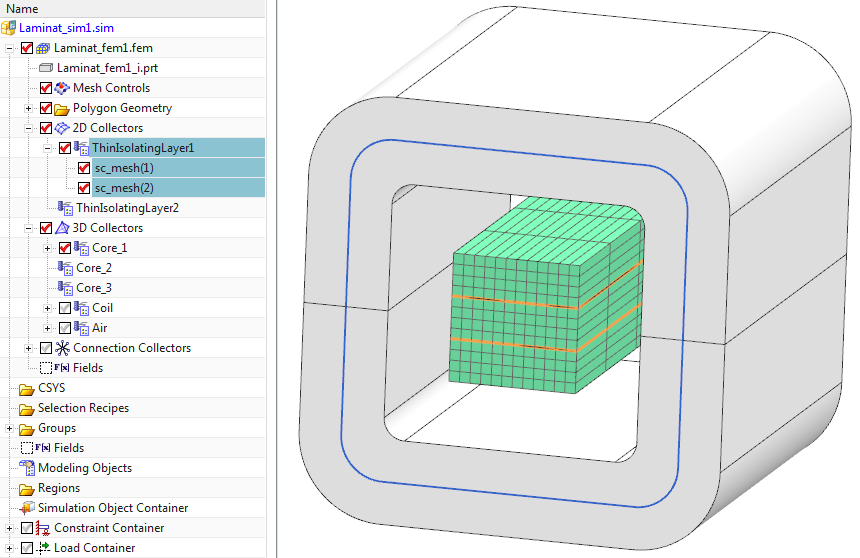

In this example there is a core in a coil running in a magnetodynamic

simulation. The core has two isolating layers which avoid eddy currents

to cross those layers. The example shows how to set up these

features.

Download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/4.MagDyn/4.6Laminate.zip

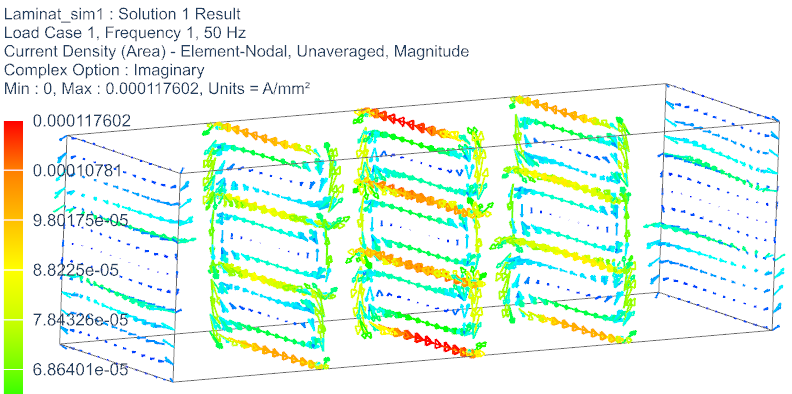

The following figure shows the meshed core and the coil. Two orange

sheets (highlighted) are the isolating layers. These are meshed in 2D

and assigned to a physical of type IsolatingLayer.

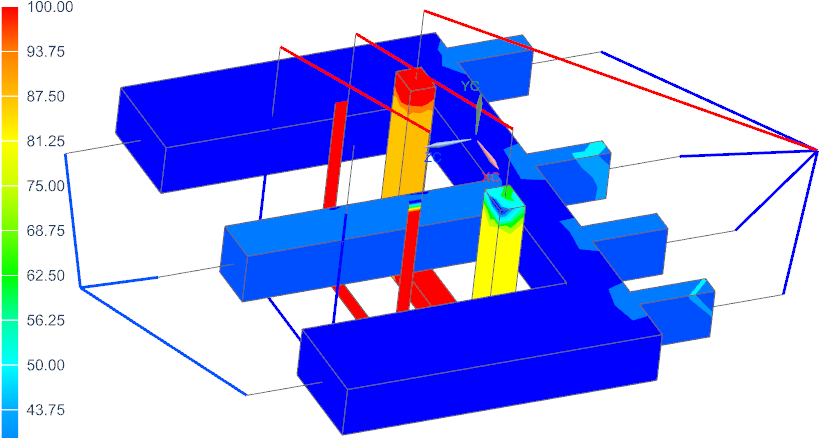

Next figure demonstrates the eddy currents in the core and how they are

hindered from crossing the isolating layers.