Magnetostatics is used when information of the magnetic field that

surrounds a conductor is needed. In this context, a DC Conduction

Steady Steate analysis is sometimes used as a preprocessing step,

and the resulting currents are used as input to a subsequent

magnetostatics analysis. This would be the case, for example, when

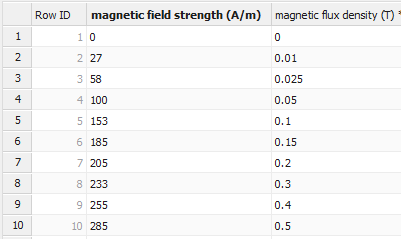

analysing electromagnets. The fundamental material property for

performing magnetostatics analysis’ is the relative magnetic

permeability \(\mu_{r}\). For nonlinear

magnetostatics analyses, a more general material relationship may be

needed, such as a functional relationship between the magnetic field and

the magnetic flux density: a so-called B-H curve. The ultimate goal of a

magnetostatics analysis is, in many cases, to compute the forces and

torques in a system of magnetic components.

Analysis of permanent magnets constitutes an important, special case of

magnetostatics analysis. In this case, a permanent magnetization is the

source of the magnetic field instead of an electrical current. In such

cases, the magnetic flux strength and direction as well as forces are

important analysis results.

In this example it is shown how to build up and analyse simple models

in 2D or axial-symmetric situations. An electric coil is positioned near

a magnetic core. The electric current in the coil creates a rotating

magnetic field (ampere law), that affects the magnetic core material. We

want to calculate for the magnetic field strength and flux density in

the core. Also, we want to find the mechanical forces acting on the

core.

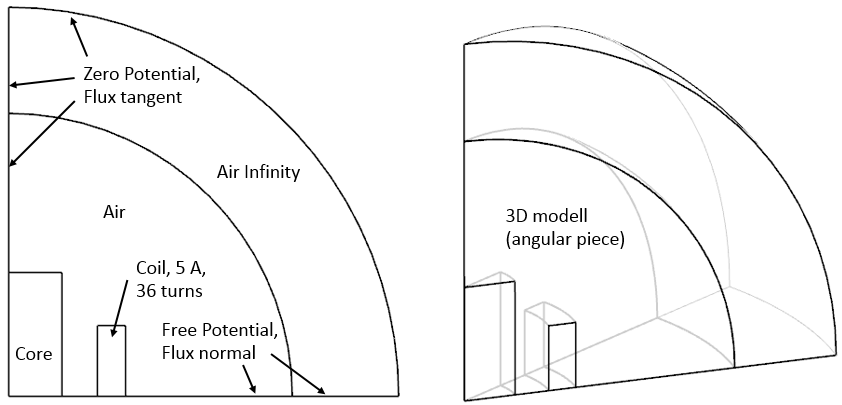

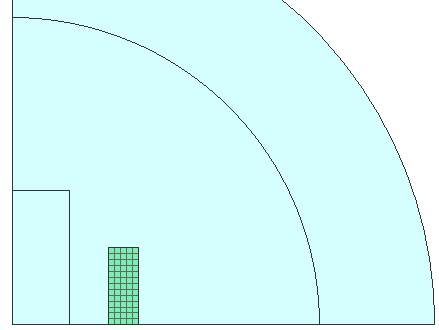

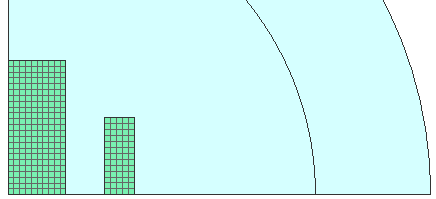

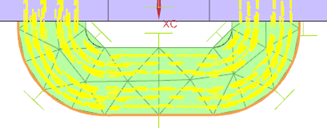

The picture below left shows a sketch representing the model. In the 2D

case, we assume an extruded geometry that is simulated by flat 2D

elements and an applied thickness (150 mm.) On the right side, there is

shown how this would look like in an axial-symmetric case (an angular

piece is shown).

The coil is loaded with electric current of 5 Ampere DC and 36

winding-turns.

Following to this 2D analysis (with thickness) we will use the same

model to analyse for the axial-symmetric situation.

Estimated time: 45 min. Follow the steps in Simcenter:

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/3.MagSta/3.1CoreInductor.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter 3D or NX. Use Version 12 or higher, preferably use the newest.

In Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’CoreInductor.prt’ and click OK. (Maybe you must set the file

filter to ’prt’)

and navigate to folder ’start’. Select

the file ’CoreInductor.prt’ and click OK. (Maybe you must set the file

filter to ’prt’)

From toolbar Application, click on ’Pre/Post’ ![]() and the system switches into the simulation application.

and the system switches into the simulation application.

Hints: All information describing the Simcenter simulation is

managed in basically three files (picture below): The Sim, the Fem and

the Idealized file. The Sim file contains the solution, boundary

conditions, loads. The Fem file contains the finite-element meshes,

material properties and other physical properties. The Idealized file is

optionally and can be used for simplifications or modifications of the

CAD geometry without changing the original CAD file.

![]()

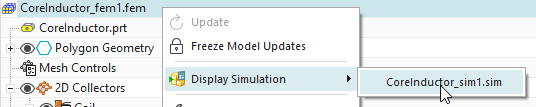

Following, we will create the Fem and Sim file structure and then we will fill it up with data. The ’Simulation Navigator’ will allow us navigating in the file-structure.

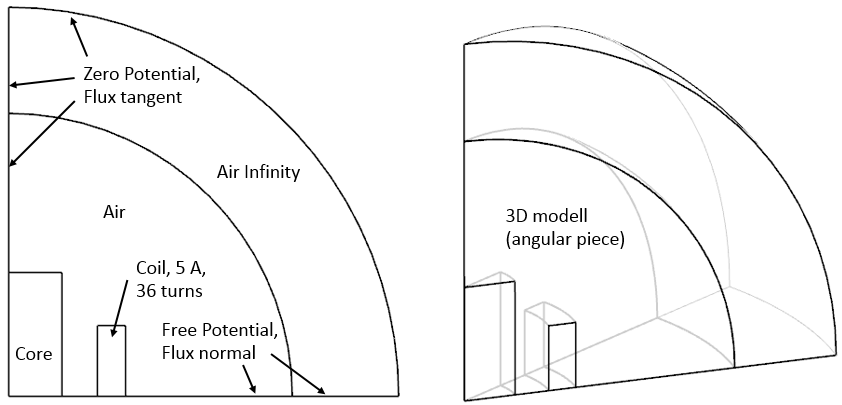

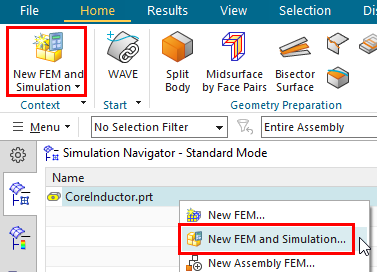

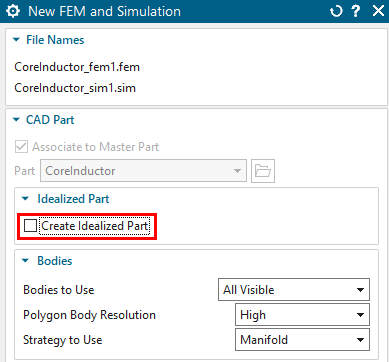

Click on ’New FEM and Simulation’ ![]() .

.

(That button is also found by RMB in Simulation-Navigator)

The window ’New FEM and Simulation’ appears.

Switch off ’Create Idealized Part’ because the geometry is already very simple.

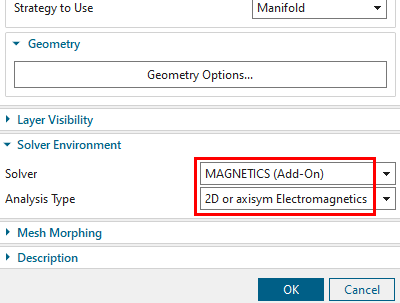

Set the Solver to MAGNETICS and Analysis Type ’2D or axisym Electromagnetics’ and click OK. The files are created.

Hint: In some cases, depending on the installation, a message

’Unsecure Solver Language File’ may appear. This can be accepted (press

Ok).

Following, a window ’Solution’ appears

(if this does not automatically appear, click on ’Create Solution’) ![]() )

)

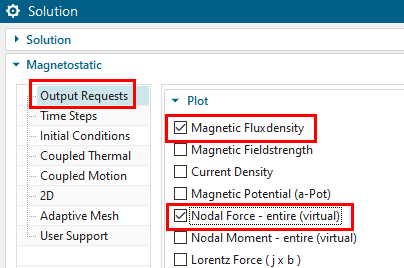

assign the Name ’Static’, accept the default Solution Type

’Magnetostatic’.

Click ’Create Solution’ and

in register ’Output Requests’, activate the results ’Magnetic

Fluxdensity’ and ’Nodal Force - entire (virtual)’.

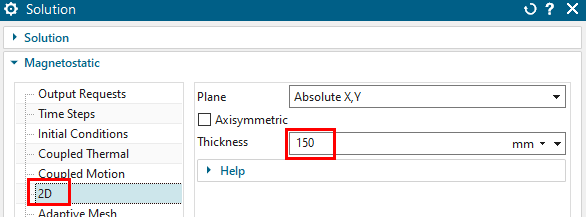

Click on register ’2D’ and set the ’Thickness’ to 150 mm.

Click OK. All other settings are well predefined. The solution will be created and the system jumps automatically to the Fem file.

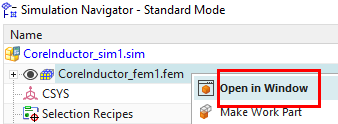

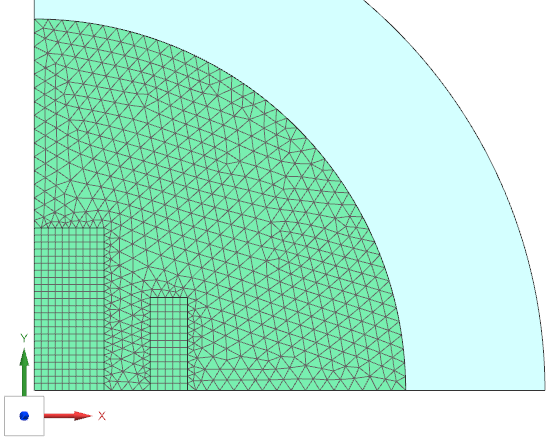

We are now going to create finite element meshes. Therefore, use

the Simulation Navigator to set the Fem file to ’Open in Window’ (if

this is not automatically done).

Mesh the Coil

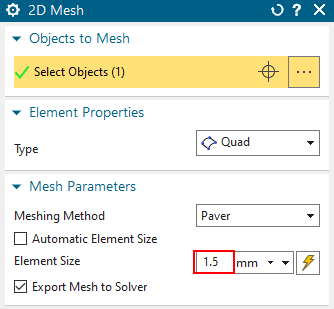

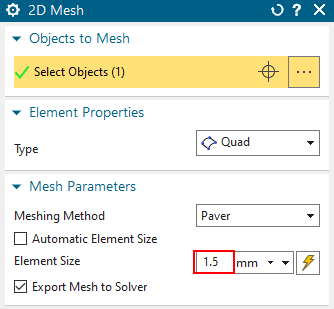

Click on ’2D Mesh’ ![]() from toolbar Home\(\rightarrow\)Mesh and select the the coil

face.

from toolbar Home\(\rightarrow\)Mesh and select the the coil

face.

Set the Type to ’Quad’ and the element size to 1.5 mm.

Click OK and the mesh is created.

Hints: We normally mesh the smallest or the most important parts

first. Tri elements would also work, we prefer quads because of their

smoothness on this quad like geometry. A reasonable ’Element Size’ can

also be found by the button ’Automatic Element Size’ and the factor

0.5.

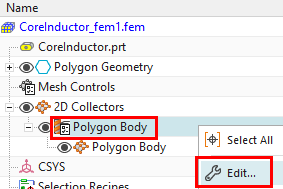

Assign Physical Properties to the Coil

Hints: The new mesh is placed inside a ’2D Mesh Collector’. That collector contains a ’Physical Property Table’. Physical properties describe mainly the material, but also other characteristics like the number of windings and more. All meshes inside a collector will use its properties.

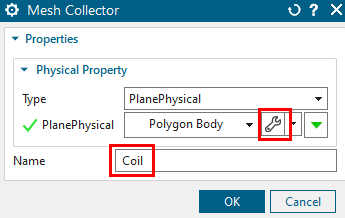

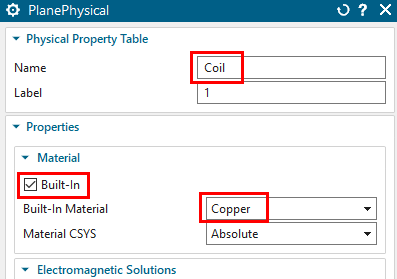

RMB and ’Edit’ the mesh collector. Set the Name to ’Coil’ and

again ’Edit’.

Hint: We accept the default physical property type ’PlanePhysical’. ![]() .

.

The window ’PlanePhysical’ appears.

At Name, again key in ’Coil’

Hint: We should assign meaningful names (particular to the physical

property) because those names will appear in post processing. Best is to

also assign the name to the mesh.

At ’Material’, click ’Built-In’ and choose ’Copper’, from the list ’Built-In Material’.

Hint: Using the Built-In materials is a simple way but it does

not allow modifying any properties. Alternatively, we can use the

’Choose Material’ ![]() button. Then, we can either create a new material or we

can select one from a library file. There exists a large library at the

following folder (it may differ depending on your installation):

button. Then, we can either create a new material or we

can select one from a library file. There exists a large library at the

following folder (it may differ depending on your installation):

\NX-folder\SIMULATION\magnet\materials\

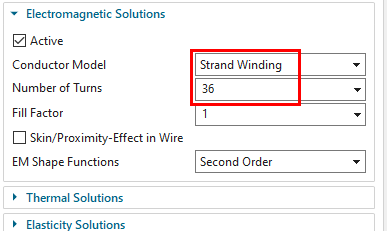

set the ’Conductor Model’ to ’Strand Winding’ and apply the value

36 for ’Number of Turns’. Accept the default 1 for ’Fill Factor’.

Hints: ’Strand Winding’ forces the electric current to flow

homogeneously and only in the winding directions, no eddy currents can

appear. The ’Fill Factor’ defines how much isolation is there. This

factor allows adjusting the coil resistance.

Click OK, OK to finish the definition of the coil.

Mesh the core:

Click on ’2D Mesh’ ![]() and select the core face.

and select the core face.

Use quad elements of 1.5 mm size. Click OK and the mesh is

created.

Assign Properties to the Core

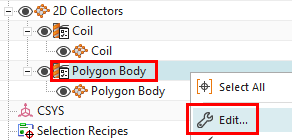

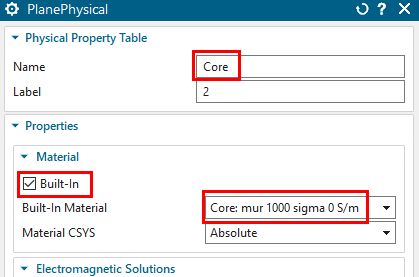

RMB and ’Edit’ the newly created 2D Collector. Set the Name to

’Core’ and click ’Edit’ ![]() . The window ’PlanePhysical’

appears.

. The window ’PlanePhysical’

appears.

At Material, click ’Built-In’ and Select from the list ’Core: mur 1000 sigma 0 S/m’, a magnetic material with relative magnetic permeability value of 1000.

Hints: We accept the default Conductor Model ’Massive’. This type

models massive metals. Thus, electric current are not forced to be

homogeneous. Eddy currents can appear.

Click OK, OK, to finish the definition of the core.

Mesh the inner air

Hint: In most cases air meshes are created as the last meshing step.

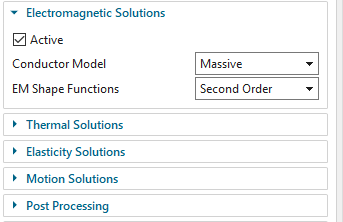

Click on ’2D Mesh’ ![]() and select the inner air

face.

and select the inner air

face.

Set the element type to ’Tri’ and the ’Element Size’ to 3

mm.

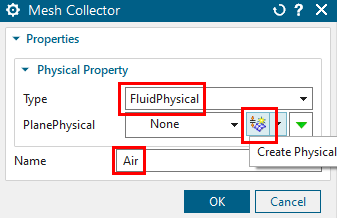

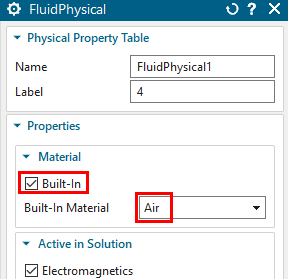

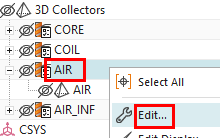

Assign Properties to the inner air

Important: Air must have a physical property type ’FluidPhysical’, not

’PlanePhysical’.

RMB and ’Edit’ the newly created mesh collector. Set the name to ’Air’

set the ’Type’ to ’FluidPhysical’ and click ’Create Physical...’

![]() . The window ’FluidPhysical’ appears.

. The window ’FluidPhysical’ appears.

At Material, click ’Built-In’ and select from the list

’Air’

Alternatively, select ’AIR’ from library

...\NX-folder\SIMULATION\magnet\materials\Commonly Used Materials.xml

Click OK, OK.

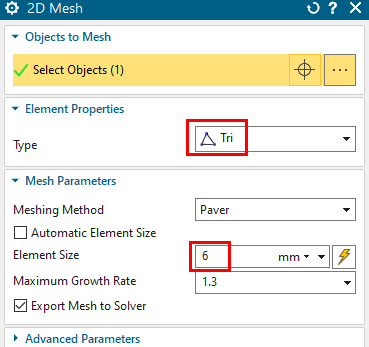

Meshing the Infinity Air

Background why infinity: The air around the core and the inductor geometry must be meshed to realistically model the magnetic (and in other cases the electric) field around these parts. This air geometry must be large enough to model the field. If it is too small, the simulation will model this field too "compressed" and the results may be inaccurate. To decide on the magnitude of this air geometry, one should also consider whether the field “wants” to leave the core and inductor geometry (flux leakage): if there is a closed iron path holding the magnetic flux, we would expect a small leakage and a large ball would not be necessary there. In our example, there is no such closed iron path and therefore we expect more leakage flux and the air geometry must be larger. Instead of a big-air geometry, there is also the option of using infinity elements. These infinity elements are to be used in our example. We used circular geometry, but other shapes like blocks would work as well. The advantage of a circular geometry is that this form is, so to speak, natural for the field lines. This also makes it easy to use Infinity elements.

Click on ’2D Mesh’ ![]() and select the outer air

face.

and select the outer air

face.

Use Tri elements of 6 mm size.

Click OK and the mesh is created.

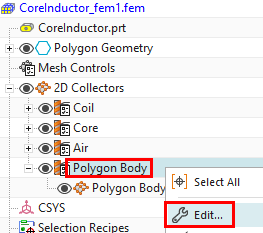

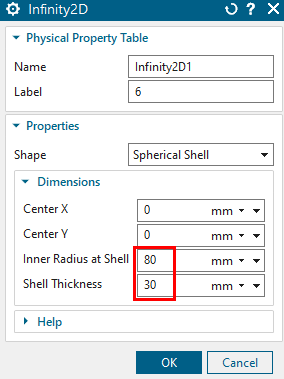

Assign Properties to the Infinity Air

RMB Edit the newly created mesh collector.

Set the Type to ’Infinity2D’ and the Name to ’Air_Inf’

Click on ’Create Physical’. A new window appears.

in the window ’Infinity2D’, key in the value 80 mm for ’Inner

Radius at Shell’ and 30 mm for ’Shell Thickness’. as shown in the

picture. The dimensions must correspond to the size of the infinity air

layer (see picture below).

Click OK, OK to create the Physical.

We are now going to create boundary conditions. Therefore, set

the Sim file to the displayed part. (The meshes are blanked here for

easier visibility)

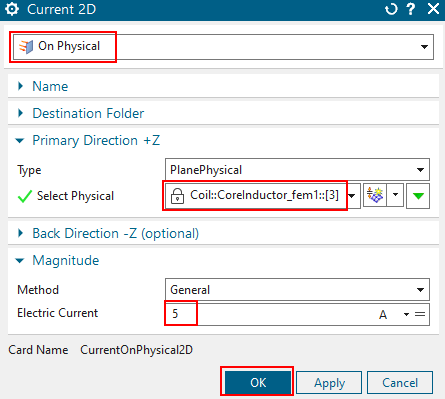

Create a load for the electric current on the coil:

Click on ’Current 2D’ ![]() from toolbar Home\(\rightarrow\)Loads and Conditions\(\rightarrow\)Load Type.

from toolbar Home\(\rightarrow\)Loads and Conditions\(\rightarrow\)Load Type.

Accept the default Type ’On Physical’.

At ’Primary Direction’, ’Select Physical’, select the Coil

Physical from the list.

Hint: the ’speaking names’ in this list only appear, if the physicals in

the Fem file have such names assigned.

Assign the value 5 A for ’Electric Current’.

Click OK and the load is created.

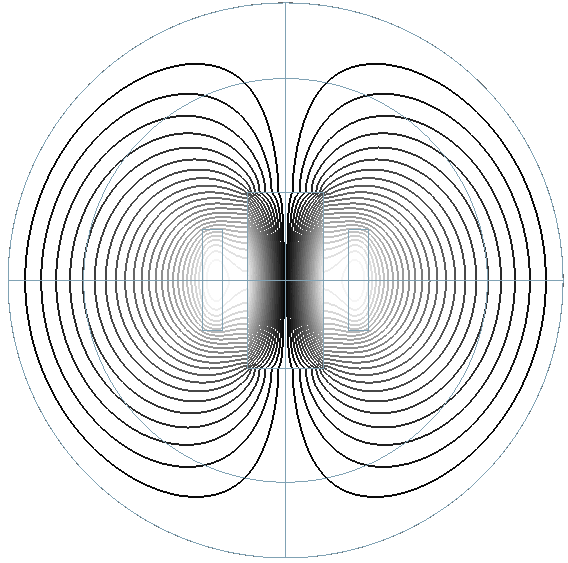

Understanding constraints

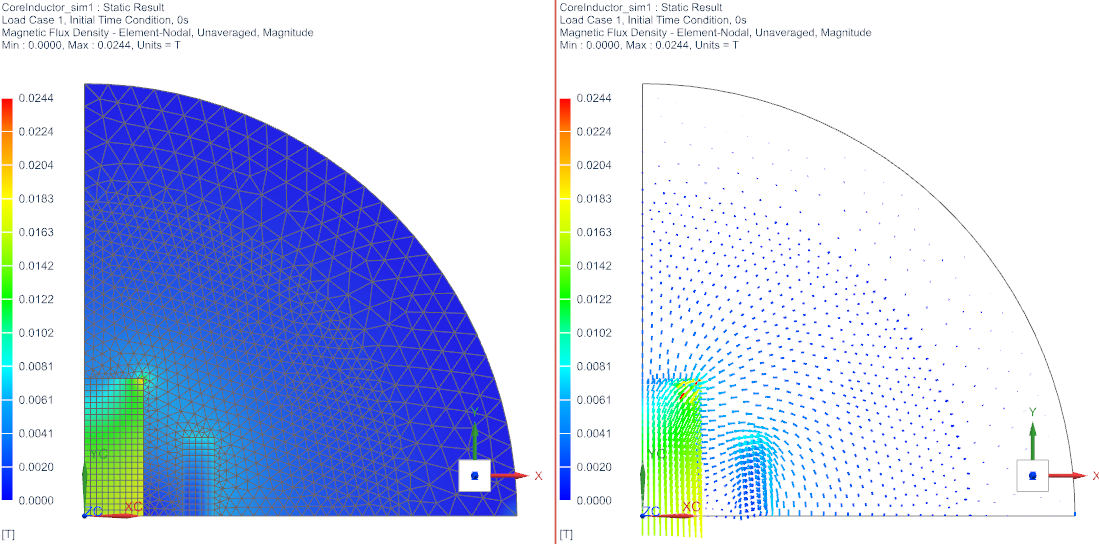

The model we use represents a quarter of the full model. Therefore, we must correctly apply constraints at all borders. The picture below left shows how magnetic field lines would appear in the case of a full model.

This allows understanding how constraints must be set in our quarter model: We need tangent magnetic field conditions at the circular border and at the vertical symmetry edges. And we need normal field conditions at the horizontal symmetry edges.

Such field lines can also be shown in the results of the

simulation: In ’Output Requests’ activate ’Magnetic Potential (a-Pot)’

and display this result in the post processor using the iso-lines

option.

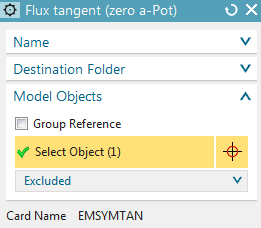

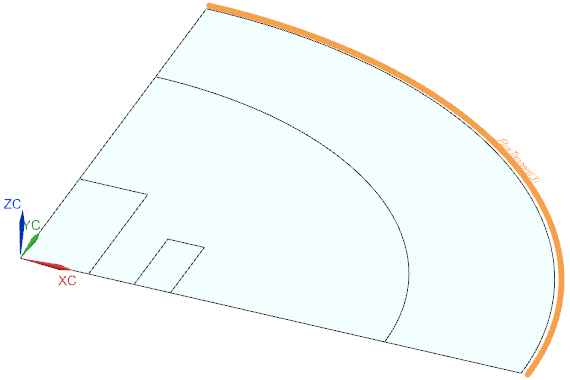

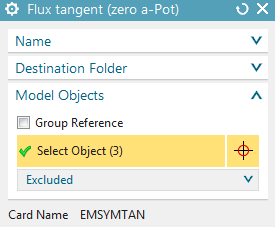

Creating constraints.

According to such needs, now we will create two tangent and one normal

constraint.

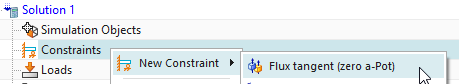

Click on ’Flux Tangent (zero a-Pot)’ ![]() from ’Constraint Type’. Select the outside circular edge and click

OK.

from ’Constraint Type’. Select the outside circular edge and click

OK.

Hint: This constraint type must always be applied at the outside

air border to keep the field from leaving the computation area.

Again click on ’Flux Tangent (zero a-Pot)’ ![]() and select the three x=0 symmetry edges. Click OK.

and select the three x=0 symmetry edges. Click OK.

Hint: Viewing the resulting magnetic field lines (pictures above)

helps understanding the symmetry condition.

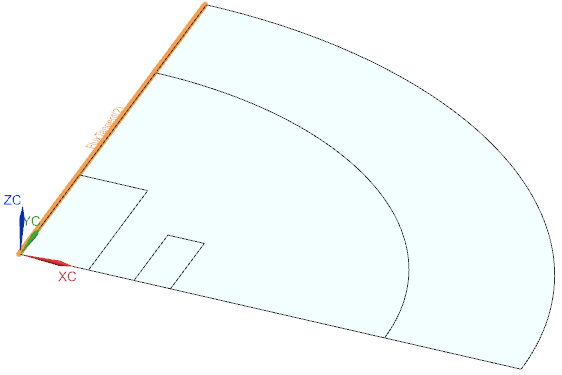

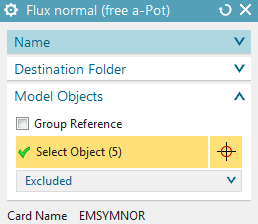

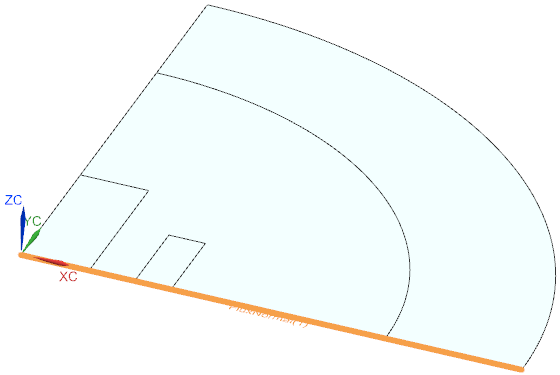

Click on ’Flux normal (free a-Pot)’ and select the five y=0

symmetry edges. Click OK to create the condition.

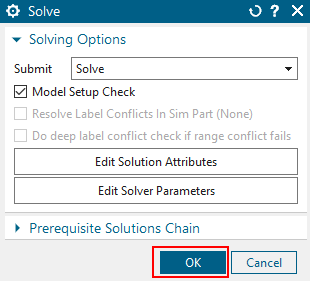

Optionally, save the files and

Click on ’Solve’ ![]() from toolbar ’Solution’. Then click OK.

from toolbar ’Solution’. Then click OK.

The solve job starts and a new window appears to monitor the solution progress. The solve job takes only a view seconds for this small model.

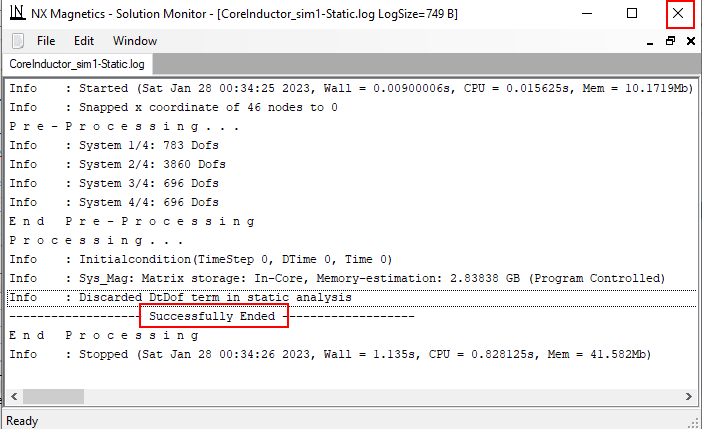

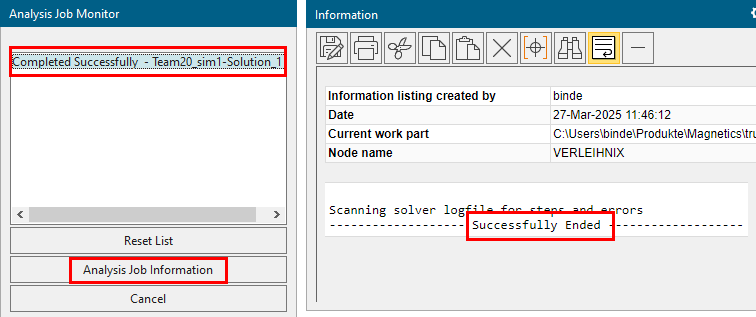

If the solution monitor shows ’Successfully Ended’, the job has

ended and there should be results. Cancel the solution monitor and also

other info windows that may have appeared.

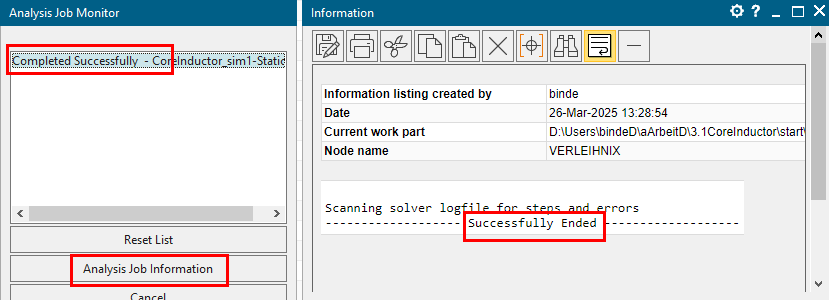

Optionally, check for solver progress and errors

In the window ’Analysis Job Monitor’, verify that it shows ’Completed Successfully’

Then, select the text ’Completed Successfully’ and click ’Analysis Job Information’

a text window will come up. If there are errors in the logfile,

it will be shown here. This information can also be requested while

solving. Then, it will show the progress (time steps or frequency steps)

of the solution.

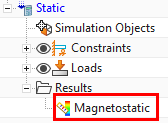

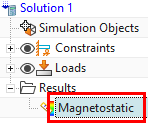

Post Processing Force Results

Double click on the ’Result’ node in the Simulation

Navigator.

Hints: The system opens the result file and switches to the post

processor. The field results are managed using the ’Post Processing

Navigator’ (see below right).

Double click on ’Force - Nodal Y’ to plot the force distribution in Y direction. There appears a PostView showing this.

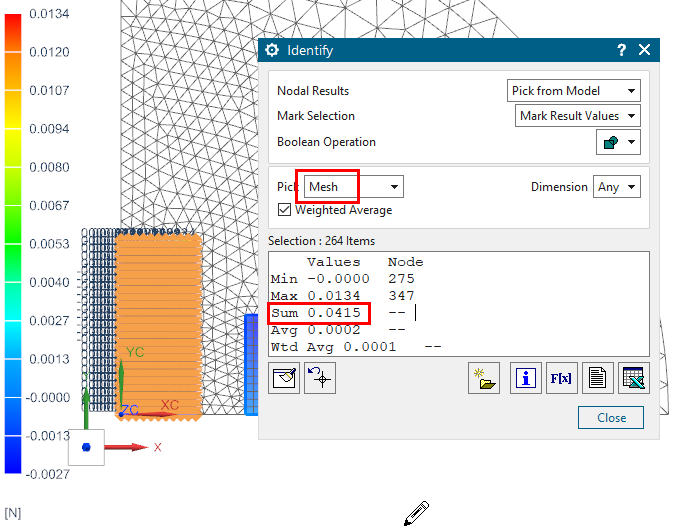

Click on ’Identify Results’ ![]() from toolbar ’Results’

from toolbar ’Results’

set ’Nodal Results’ to ’Pick from Model’ and option ’Pick’ to ’Mesh’ and select the face of the core.

The sum of all values on the core is evaluated and written into

the ’Identify’ window. This resulting force sum is about 0.04 N.

Hints: The defined thickness value of 150 mm is already taken into

account.

Post Processing Magnetic Flux Density

To plot the distribution of magnetic flux density, double click on ’Magnetic Flux Density’, ’Magnitude’.

to display the magnetic flux density by arrows, switch from

’Contour’ to ’Arrows’ in toolbar ’Results’. These vectors show the

direction of the field lines.

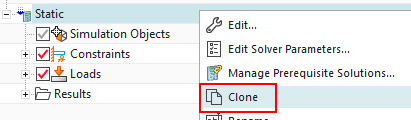

To analyze in an axial symmetric way (axis is Y) using the same geometry follow these steps:

Clone the solution and

Rename the new solution to ’Axisym1’.

Choose ’Edit Solution’ on the new ’Axisym1’ and switch to

register ’2D’. Activate ’Axisymmetric’ and click OK.

Hint: To use axis symmetric analysis, it is necessary to place all

elements on the x/y plane for positive x. The axis must be Y.

Solve the solution ![]() and post process the results:

and post process the results:

Check the force sum in Y direction again. It should be about 0.08 N. The axisymmetric effect (2*Pi) is already taken into account.

The tutorial is complete. Save your files and close them.

This example is a convenient training for all those who want to do

electromagnetic analysis with complex 3D geometries, because it contains

most necessary skills for dealing with this.

The Team20 benchmark is a test example for electromagnetic analysis

software tools. There are measured force-results available that we will

use for comparison with the simulation-results. We will use a nonlinear

B-H curve that includes saturation effects for the core and iron

parts.

For meshing, we want to exploit the ’Non-Manifold’ strategy, which

automatically finds adjacent face pairs and creates conformal meshes

(e.g. coincident nodes) at those interfaces. Thus, no Mesh-Mating

conditions are needed any more. This feature is very powerful but only

available in the newer versions of Simcenter/NX (best in 2406 or

later).

Necessary time: 1 h.

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/3.MagSta/3.2Team20.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter 3D or NX. Use Version 12 or higher, preferably use the newest.

Optionally: Enable ’Use Polygon Body Names for Meshes’. Find it here: File, Utilities, Customer Defaults. Then: Simulation, Pre-Post, Meshing, General.

In NX/Simcenter, click Open ![]() and navigate to folder ’start’. Select

the file ’Team20.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

and navigate to folder ’start’. Select

the file ’Team20.prt’ and click OK. (Maybe you must set the file filter

to ’prt’)

From toolbar ’Application’, click on ’Pre/Post’ ![]() and the system switches into the simulation application.

and the system switches into the simulation application.

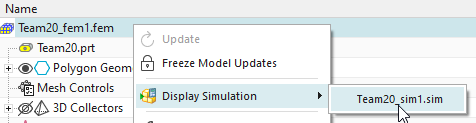

All information describing the simulation is managed in basically

three files (see below): The Sim, the

Fem and the Idealized file. The Sim

file contains the solution, boundary conditions, loads. The Fem file

contains the meshes, material properties and other physical properties.

The Idealized file is optionally and can be used for simplifications or

modifications of the geometry without changing the original CAD

file.

![]()

Following, we will first create this file structure and then we will

fill it up. The ’Simulation Navigator’ will allow us navigating through

the structure.

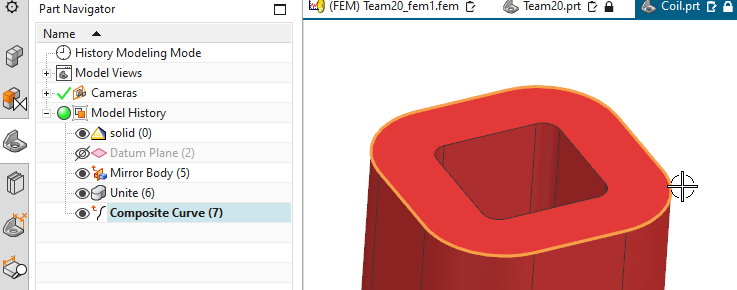

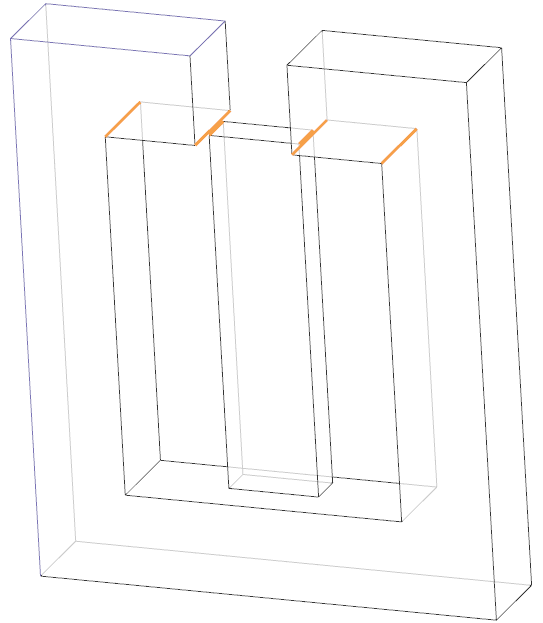

Notice, in the CAD Model, there is a spline

curve extracted from the outside edges of the coil (see

highlighted in below picture). This spline will be used to define the

winding directions. It is necessary, that this spline is one single

curve. In case there are multiple curve segments, there must be done a

’Join Curve’ operation to make one spline out of them. We will later

have to activate one special button to transfer this spline into the Fem

file.

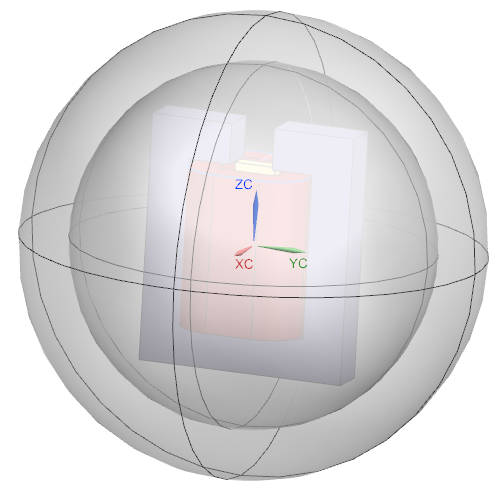

A spherical air volume is placed around the

solid geometry and an additional spherical shell is placed around the

sphere. This sphere is necessary to model the magnetic (and in other

cases also the electric) field in air. The shell additionally models the

infinity air. We could solve without the infinity air, but in that case

the air volume would have to be large enough to model the field. In case

it would be too small, the simulation would model that field too much

‘compressed’ and results would become inaccurate. To decide about the

size of such an air volume, it should also be considered whether the

field ‘wants’ to leave the solid geometry (flux leakage): If there is a

closed iron path, holding the magnetic flux like in our case, there is

no need for a big sphere. In other cases, there may appear more flux

leakage and the air volume should be larger. Instead of using a large

air volume, we rather want to use infinity elements just like we already

did in the previous tutorial ‘Core and Inductor’. In this example, we

use a sphere, but alternatively box geometries would work as well.

Advantage of a sphere is that it is kind of natural for the field lines.

Also this makes it simple using infinity elements.

Following, we will create the Fem and Sim file structure and then we will fill it up with data. The ’Simulation Navigator’ will allow us navigating in the file-structure.

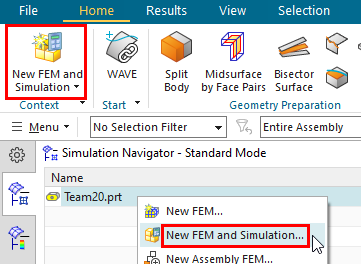

Click on ’New FEM and Simulation’ ![]() .

.

(That button is also found by RMB in Simulation-Navigator. The picture

shows both)

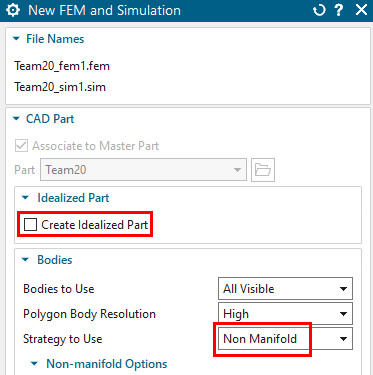

The window ’New FEM and Simulation’ appears.

Switch off ’Create Idealized Part’ because the geometry is already very simple.

Set the ’Strategy to Use’ to ’Non Manifold’.

Hint: By this way, we don’t need Mesh-Matings. If the SC/NX version is

older than 2406, see chapter ’Recommended System Settings, Create

Non-Manifold Polygon Bodies’. Alternatively, create the conventional

Mesh-Matings.

Set the Solver to MAGNETICS and Analysis Type ’3D Electromagnetics’ and click OK. The files are created.

Hint: In some cases, depending on the installation, a message

’Unsecure Solver Language File’ may appear. This can be accepted (press

Ok).

In toolbar ’Home’, click on ’Create Solution’ ![]()

Hint: sometimes this is automatically triggered.

Accept the Solver ’MAGNETICS’ and the Analysis Type ’3D Electromagnetics’,

Accept the default Solution Type ’Magnetostatic’.

Click ’Create Solution’.

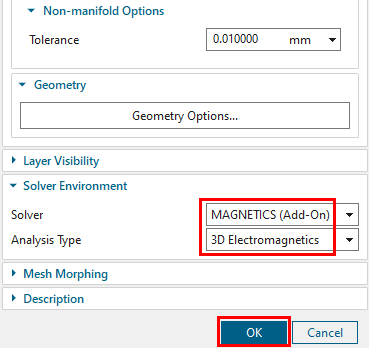

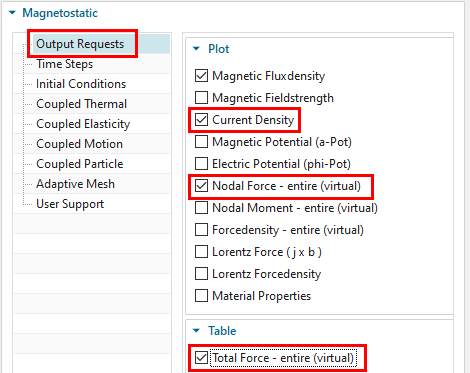

In register ’Output Requests’, ’Table’, activate ’Total Force - entire (virtual)’ to enable the system calculate forces by the virtual energy method.

to see these forces in the plots and also the applied currents,

also activate in ’Plot’ ’Current Density’ and ’Nodal Forces - entire

(virtual)’.

Click OK to finish the Solution window.

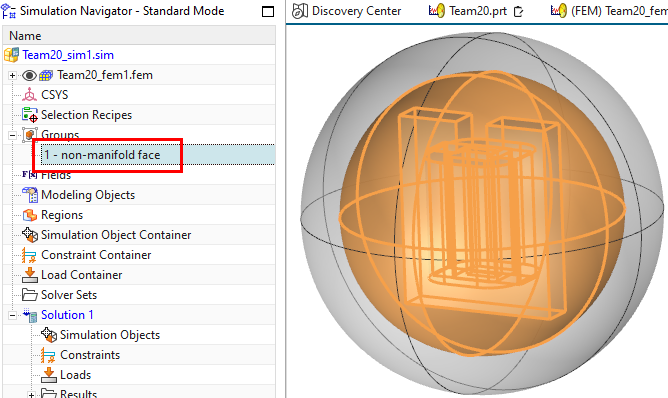

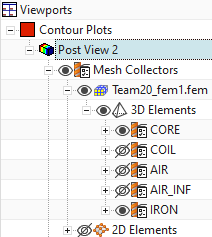

In the Simulation-Navigator, at ’Groups’, verify that there is a group with name ’non-manifold face’

select that group and observe that faces are highlighted. These

are those faces that belong to two bodies. Those faces are such that in

older versions would need Mesh-Mating-Conditions. Here, the meshes need

coincident nodes. That requirement will now automatically be

fulfilled.

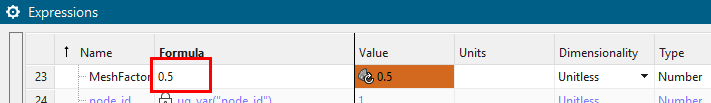

Following, we will create all element-sizes using one control-parameter ’MeshFactor’. This makes it simple later to do studies with different mesh-sizes and therefore, we recommend this approach.

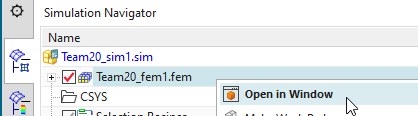

Do a ’Open in Window’ to the Fem part.

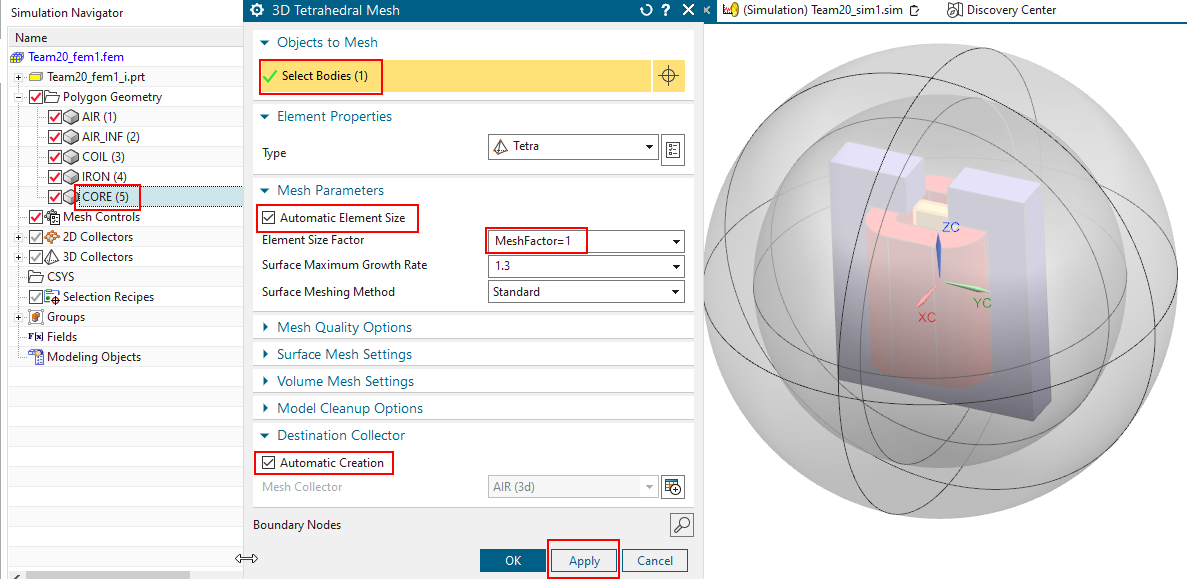

Mesh the CORE: Start the mesher ’3D Tetrahedral’ ![]() , select the core body (either in the graphics window or

in the Polygon Geometry list) and activate ’Automatic Element Size’. In

the field ’Element Size Factor’, key in the text ’MeshFactor=1’ to

create a parametric expression ’MeshFactor’. click ’Apply’. The mesh is

created.

, select the core body (either in the graphics window or

in the Polygon Geometry list) and activate ’Automatic Element Size’. In

the field ’Element Size Factor’, key in the text ’MeshFactor=1’ to

create a parametric expression ’MeshFactor’. click ’Apply’. The mesh is

created.

Mesh the remaining parts with the same settings as follows:

Select the IRON body, click ’Apply’.

Select the COIL body, click ’Apply’.

Select the AIR body, click ’Apply’.

Select the AIR_INF body, click ’OK’.

Hint: the order of creation of meshes is important: We should always

start with the most important parts.

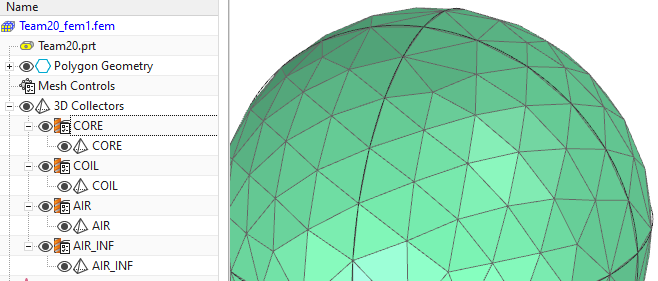

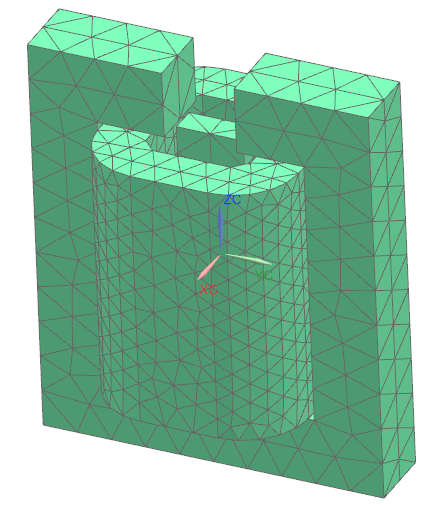

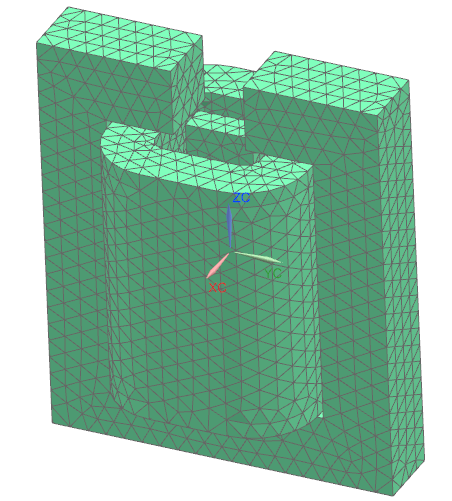

The meshes are still quite coarse, because of the MeshFactor=1.

We want to globally reduce the mesh size to the half. Thus, change the

expression ’MeshFactor’ to 0.5. This is done in the ’Expressions’ window

(Menu, Tools, Utilities, Expressions).

After the new value is set, click the ’Update’ button. A

re-meshing starts and all elements will become smaller.

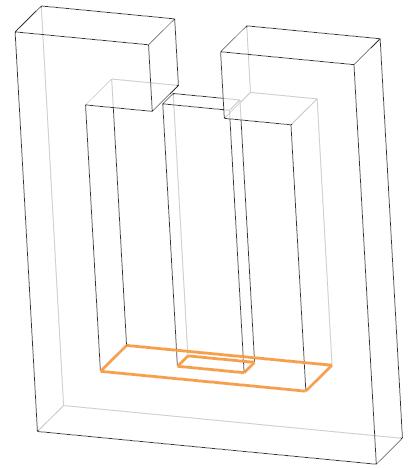

The picture below shows left the old and right the new meshes of core,

iron and coil.

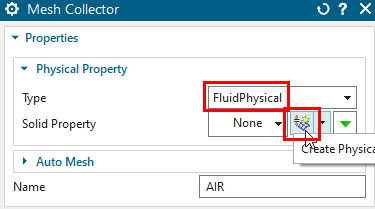

Important: Air must have a physical property type ’FluidPhysical’, not ’SolidPhysical’.

Right mouse button (RMB) and ’Edit’ the mesh collector of the Air.

Set the ’Type’ to ’FluidPhysical’ and click ’Create Physical’

at ’Material’, activate ’Built-In’ and select ’Air’ from the

list, click OK, OK

Alternatively, select ’AIR’ from library

...\NX-folder\SIMULATION\magnet\materials\Commonly Used Materials.xml

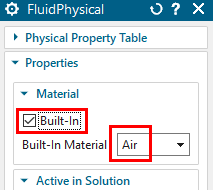

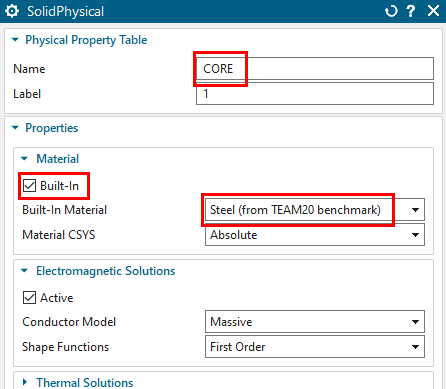

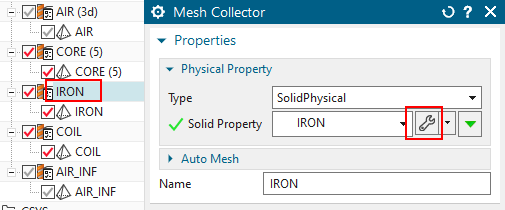

RMB and ’Edit’ the mesh collector of the core.

Accept the default physical property of type ’SolidPhysical’ and

click ’Edit’. The window ’SolidPhysical’ appears.

at Material, activate ’Built-In’

from the list ’Built-In Materials’, select ’Steel (from TEAM20

benchmark)’

Hint: This built-in material has the same properties as the one we

create individually in the following chapter.

Click OK, OK to finish the windows.

Proceed in the same way for the iron part.

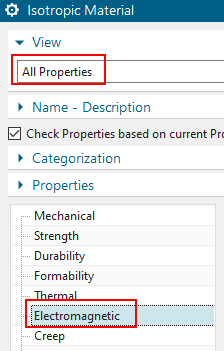

As an alternative to the prior chapter, here we define a typical steel material for the core and iron bodies. This material shows a nonlinear relationship between magnetic flux-density (B) and magnetic field-strength (H). Such a relation is often the case for steel and iron. Many material properties are already available in the material library, but often, we must insert individual data and define a individual material. The data points with H-B pairs are stored in a csv file (Team20MaterialCurve.csv) in the ’start’ folder of this tutorial. Proceed as follows to create a new material with these:

Click ’Manage Materials’ ![]() and ’Create Material’

and ’Create Material’ ![]() at the bottom right.

at the bottom right.

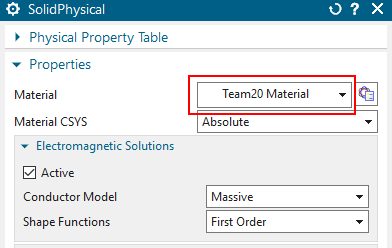

Set ’View’ to ’All Properties’ and select the register

’Electromagnetics’. Key in a name, for instance ’Team20 Material’. Set

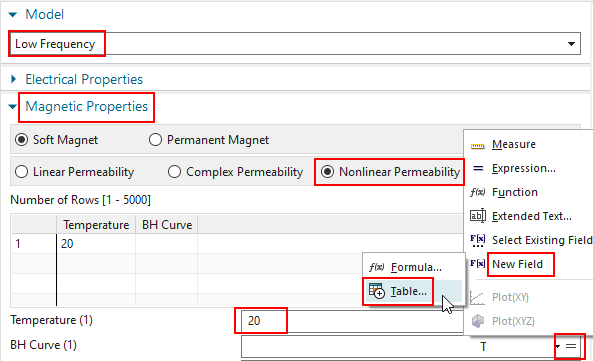

the ’Model’ to ’Low Frequency’ (see below).

Scroll down and set ’Magnetic Properties’ to ’Nonlinear Permeability’ (above right). Key in a ’Temperature’ of 20 degrees Celsius.

Right to field ’BH Curve’, select the ’\(=\)’ and choose ’New Field’ and click ’Table’.

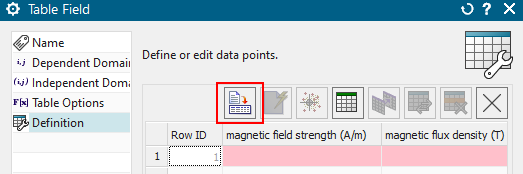

In the next window, select ’Import from Text File’ and scroll to

the ’start’ folder of this tutorial. Select the file

’Team20MaterialCurve.csv’ and click OK. The picture below right shows

the ’Table Field’ window with the new data.

Click OK, Close. The material is now created.

Assign the new material to the core and also to the iron:

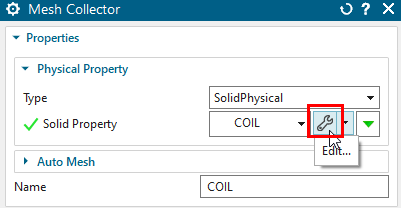

Following, we will define the properties of the coil. Even though the CAD model is a simple solid, in the simulation we want to model the electric current as flowing through windings. As a side effect, there will be no eddy currents in the coil.

Edit the Physical of the coil mesh.

At ’Material’, select ’Built-In’ and choose ’Copper’ from the

list ’Built-In Material’.

Hint: Alternatively, use ’Choose Material’ and select one from the

library.

In the box ’Conductor Model’, set the options as follows:

Set ’Model’ to ’Stranded, Vectors defined in Mesh Associated Data’. This allows forcing all electric currents flowing in directions of the winding. Using this stranded method you will get a homogeneous distribution of the current over the face. In a following step we will define these directions using a spline curve.

Set ’Number of Turns’ to 1000,

Accept ’Fillfactor’ is 1, This setting influences the ohm resistance of the coil.

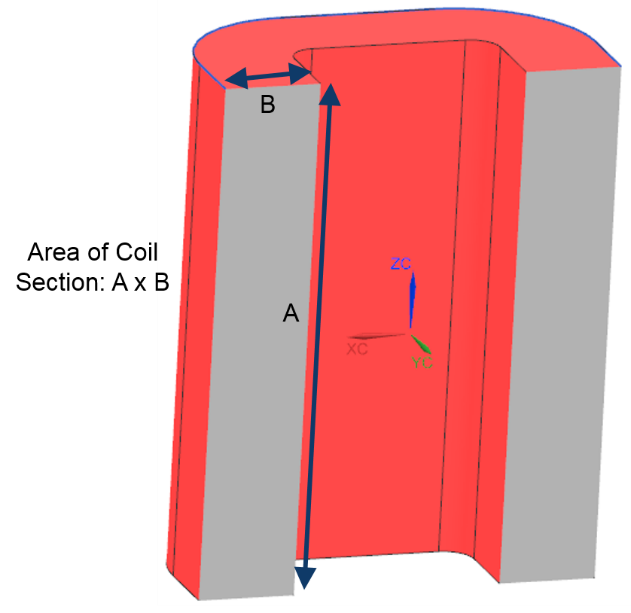

Set ’Coil Section Area’ to 1738.8 mm\(^{2}\). See next picture (right) for an

explanation how this area is computed.

Click OK, OK.

Define the stranded winding directions:

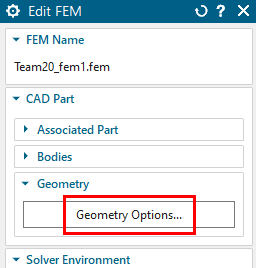

We first have to add the spline curve into the Fem file, which in

CAD was extracted from the coil edges. To do this: RMB, ’Edit’ the Fem

file, click ’Geometry Options’ and activate ’Splines’. Click OK,

OK.

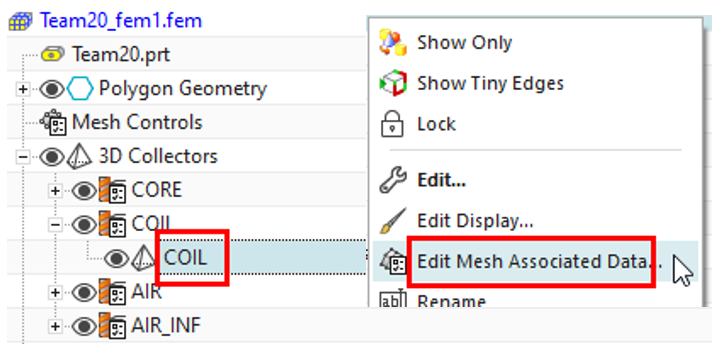

Now, do RMB on the mesh (not the collector!) of the coil, Choose

’Edit Mesh Associated Data’.

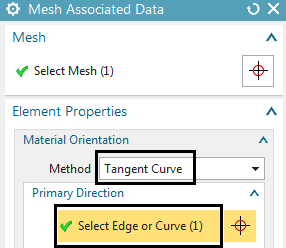

In the next window, set the option ’Material Orientation’ to

’Tangent Curve’ and select the spline curve for the stranded winding

direction. (Blank the meshes and air volumes for easier selection)

Hint: Maybe, the spline curve is not visible. In that case, you have to fully load the CAD file of the coil. Therefore, simply make the coil the work part once.

Hint: You can activate ’Preview’ to see the arrows pointing in

positive direction. If later, current is defined on this coil, it will

be forced in this direction.

Click OK, OK to finish the coil definition.

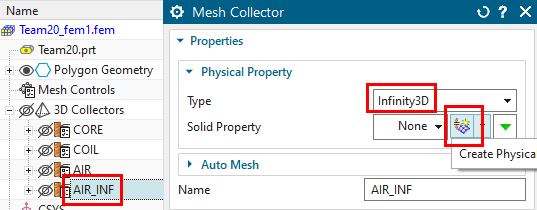

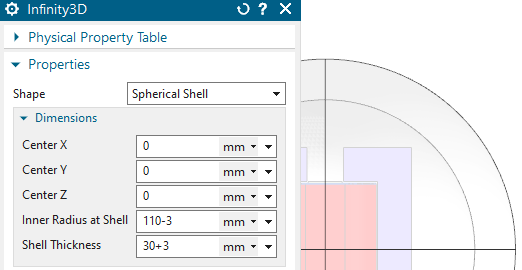

Edit the mesh collector ’AIR_INF’, set the ’Type’ to

’Infinity3D’, select ’Create Physical’, accept the default type

’Spherical Shell’ and key in the two values for ’Inner Radius at Shell’

and ’Shell Thickness’ as shown below. Click OK, OK.

Hint: The value ’Inner Radius at Shell’ is slightly reduced (3 mm, and

the thickness value adds 3 mm to compensate) to avoid error messages

like ’Bad parameters for transformation Jacobian’ that may appear from

the solver. The reason for that error is that all elements of AIR_INF

must be inside the two radii. But if the mesh is coarse, there may some

element-edges crossing the radius value. To allow also these elements,

we do that reduction.

To finish the work in the Fem file it is a good practice to blank all meshes and unblank all polygon bodies.

Switch to the Sim file.

To keep the magnetic flux inside the air sphere, it is necessary

to use a constraint ’Flux tangent’. To do so, click on ’Constraints\(\rightarrow\)’New Constraint’\(\rightarrow\)’Flux tangent (zero a-Pot)’

![]() . Select all 8 outside faces of the air volume (selection

filter ’Tangent Faces’ helps). Click OK.

. Select all 8 outside faces of the air volume (selection

filter ’Tangent Faces’ helps). Click OK.

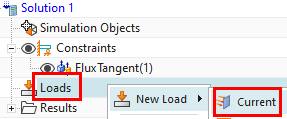

To create an electric current load for the coil:

At loads, click on ’New Load’ and ’Current’

Accept the default type ’On Stranded Coil’ and also the default Method ’General’

key in 3 A at ’Electric Current’.

Hint: The positive direction of the current is defined by the spline

that was selected in ’Mesh Associated Data’. If desired, use \(-3\) to switch the direction.

In the list ’Select Physical’, select the ’Coil’ and click

OK.

Optionally save the parts

Solve the solution: Click on ![]() and OK. The solver will run about 20 sec.

and OK. The solver will run about 20 sec.

Optionally, check for solver progress and errors:

In the window ’Analysis Job Monitor’, verify that it shows ’Completed Successfully’

Then, select the text ’Completed Successfully’ and click ’Analysis Job Information’

a text window will come up. If there are errors in the logfile,

it will be shown here. This information can also be requested while

solving. Then, it will show the progress (time steps or frequency steps)

of the solution.

Close all windows that came up (Analysis Job Monitor, Information Window, Solution Monitor)

Post processing

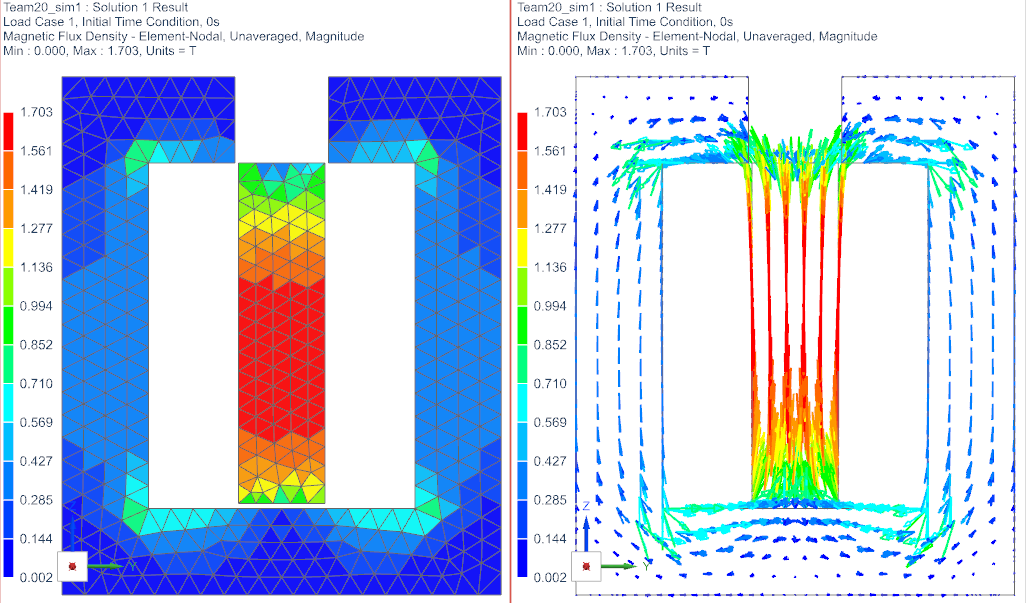

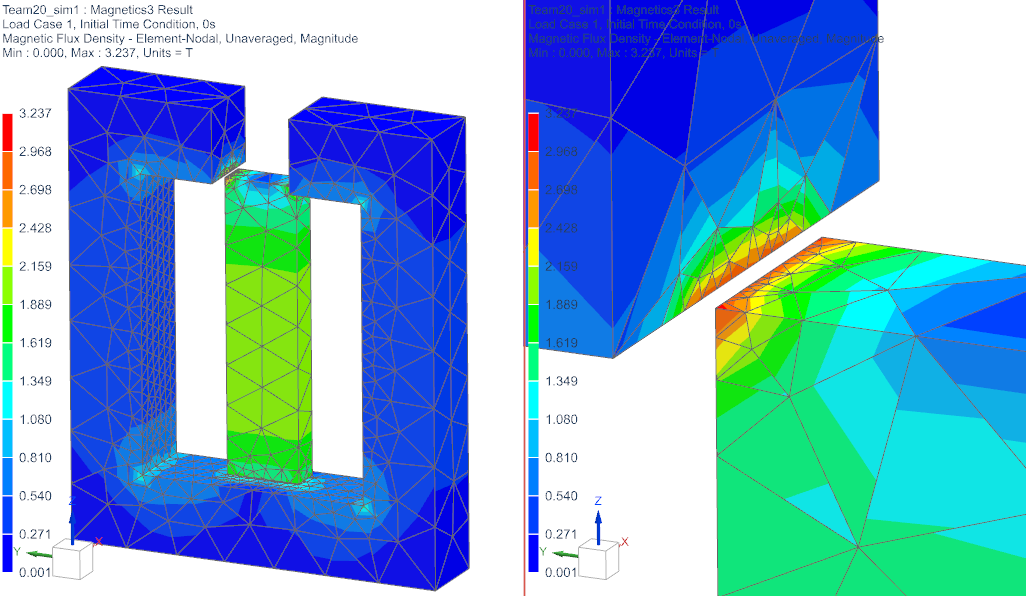

After the solver has finished, open the results by double clicking on the ’Results’ node. Then, in the ’Post Processing Navigator’, open the node ’Solution1’ and double click on ’Magnetic Flux Density’.

Also in ’Post Processing Navigator’, hide the AIR, AIR_INF and

COIL meshes by switching off their red symbols at ’Viewports’. Now the

results can be seen in graphics.

The maximum Flux density in the core should be about 1.7 Tesla.

The below picture shows Contour (left) and Arrows (right).

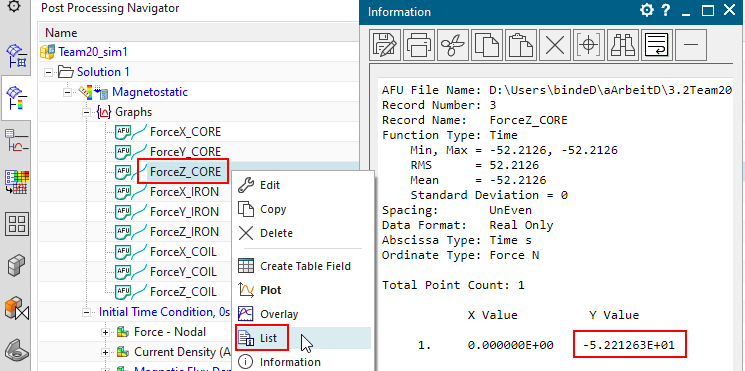

Tabular results, like force sum on all bodies or currents, are

found at the top of the results node, as seen in the below picture. From

there, the requested results can be opened and shown by ’List’ or in a

graph window by ’Plot’.

The Z-direction force is computed to -52.2 N.

Notice: The measured reference force is -54.4 N.

Variants with 3A, 4.5A and 5A

We want to compute two other electric currents and compare them with

reference measurements. Solve using the following values for the current

and compare the results against measurement data (Reference data is from

[TakahashiNakataMorishige]).

3.0 A: Measurement: -54.4 N. Simulation: -52.2 N Deviation: 4%

4.5 A: Measurement: -75.0 N. Simulation: -80.4 N Deviation: 7.2%

5.0 A: Measurement: -80.1 N. Simulation: -88.5 N Deviation: 10.4%

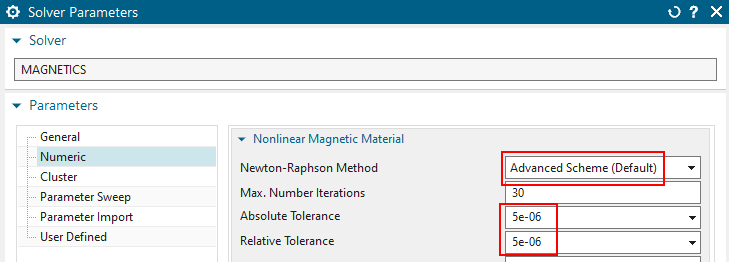

Loss of accuracy normally results mainly from the mesh because of the approximation of finite elements. Thus, finer meshes or using higher order shape functions will help. On the other side, if there is an nonlinear material included, there also results some loss of accuracy from the nonlinear scheme what can be controlled by the residual tolerances. We will use both in the following.

Because we us a nonlinear BH curve in one of the materials, there runs a Newton-Raphson-Iteration-loop in the solver. Tolerances control how tight our solution will be to the given BH curve. Thus, the first thing we do is reduce this tolerance by one order. Proceed as follows:

RMB on the solution, click ’Edit Solver Parameters’. In register ’Numeric’, box ’Nonlinear Magnetic Material’, set ’Newton-Raphson-Method’ to ’Advanced Scheme (Default)’.

reduce the two tolerances by one order, thus, from 5e-5 to

5e-6.

Solve again for the three currents and compare the force results. You may also notice in the logfile that the number of required iterations to converge increases.

3.0 A: Measurement: -54.4 N. Simulation: -51.6 N Deviation: 5.1%

4.5 A: Measurement: -75.0 N. Simulation: -75.1 N Deviation: 0.1%

5.0 A: Measurement: -80.1 N. Simulation: -80.9 N Deviation: 1.0%

now we reduce the two tolerances again by one order to 5e-7. Solve again and find: results are the same as before. Thus, the prior tolerance 5e-6 worked already well.

Set the two tolerances back to 5e-6.

The shape functions define the approximation of the main result in

the finite elements. we can increase the order without changing the

mesh. We use so called hierarchical shape functions, that means, no

midnode elements are necessary. Increasing the order strongly increases

the number of degrees of freedom (DOFs or unknowns) in the equation

system. This results in more solve time and much more necessary memory

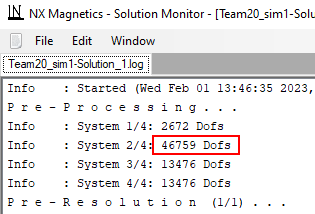

(RAM). The number of DOFs is shown in the solution monitor quite at the

beginning. There are several systems shown. The relevant one is simply

the largest one. The picture below shows the DOFs with the origin (first

order) left and a solve with third order on the right. Notice, that the

number has increased by a factor of nearly 5.

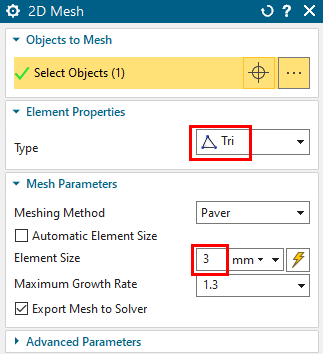

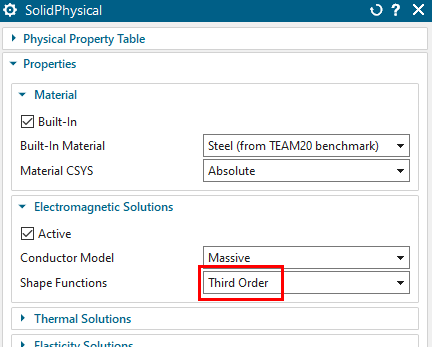

To test with third instead of first order, do this:

switch to the Fem file,

edit the physicals of Core, Iron, Air (if you want, also the coil) and for each of them

in box ’Electromagnetic Solutions’, set the ’Shape Functions’ to

’Third Order’.

solve again for the three currents. The solve time will increase a lot. Compare the results:

3.0 A: Measurement: -54.4 N. Simulation: -54.39 N Deviation: 0.02%

4.5 A: Measurement: -75.0 N. Simulation: -74.37 N Deviation: 0.84%

5.0 A: Measurement: -80.1 N. Simulation: -79.64 N Deviation: 0.57%

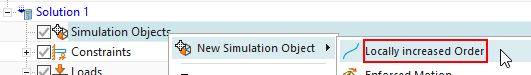

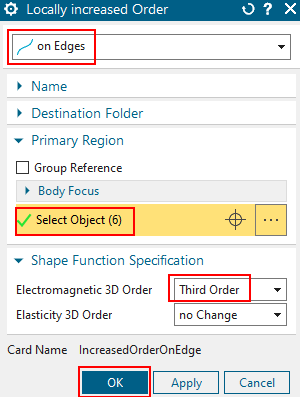

Because the globally increased order of shape functions strongly increases the number of DOFs, there exists a feature for increasing that order on elements being connected to edges or faces. This is often a good compromise because the DOFs increase only slightly but the accurate shape functions are installed. For good efficiency, we should select faces or edges with sharp corners. Or simply those, where the magnetic fluxdensity changes rapidly. Proceed as follows for a test:

switch back to the Fem file and set all physical shape functions back to ’First Order’

switch to the Sim file.

Create a ’Simulation Object’ of type ’Locally increased

Order’

Accept the default type ’on Edges’ and select the 6 sharp corner

edges at the upper side, where we have already seen the magnetic

fluxdensity changing rapidly. These are shown in the picture.

In ’Electromagnetic 3D Order’, set the ’Shape Function’ to ’Third Order’

Create another ’Locally increased Order’, now set the type to ’on

Faces’ and select the two faces at the lower side, where the flux jumps

over the air-gap between the core and iron. Set the order to 3 here

too.

solve again for the three currents. Notice, that we now have 53345 DOFs, only a little more than with full first order.

3.0 A: Measurement: -54.4 N. Simulation: -54.96 N Deviation: 1.03%

4.5 A: Measurement: -75.0 N. Simulation: -74.02 N Deviation: 1.31%

5.0 A: Measurement: -80.1 N. Simulation: -78.90 N Deviation: 1.50%

To increase the result accuracy, one can also use adaptive meshing.

Remove the two ’Locally increased Order’ features from the model first.

set the core, iron and air physicals to ’Third Order’.

Activate the button ’Perform Adaptive Meshing’ in the edit

solution dialogue at register ’Adaptive Mesh’ as shown in the below

picture. All default settings, as seen below, can stay in many

cases.

The feature adaptive meshing takes more time to solve because it reflects the results and changes the mesh to find an optimal mesh. Therefore, it should be used only with one electric current value. For the other values, it should be switched off, so the system will use the already adapted mesh. Using this, we get the final result values as shown below.

3.0 A: Simulation: -55.40 N Deviation: 1.8%

4.5 A: Simulation: -75.99 N Deviation: 1.3%

5.0 A: Simulation: -81.32 N Deviation: 1.5%

The mesh, as it comes out of the adaptive meshing process, is

demonstrated in the below picture.

This tutorial is complete. Save your files and close them.

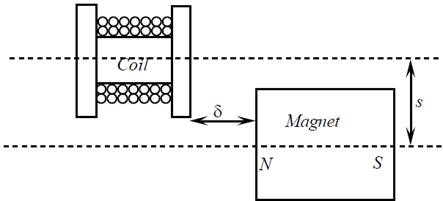

In this tutorial forces between a coil and core are computed in 2D at different positions. A parameter sweep is performed to vary different CAD positions of the magnet. The model is already set up, we just have to create a second solution with a parameter sweep.

download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/3.MagSta/3.3ForceMagnetTeam23.zip

unzip the archive. There will be one folder ’start’ and one ’complete’.

Start the Program Simcenter 3D or NX. Use Version 12 or higher, preferably use the newest.

In Simcenter, click Open ![]() and navigate to folder ’complete’.

Select the file ’Team23_sim1.sim’ and click OK. (Maybe you must set the

file filter to ’.sim’) This file already contains the meshes, physical

properties, loads and constraints.

and navigate to folder ’complete’.

Select the file ’Team23_sim1.sim’ and click OK. (Maybe you must set the

file filter to ’.sim’) This file already contains the meshes, physical

properties, loads and constraints.

Create a new Solution ![]() .

.

Key in for name ’2nd_Order_VarDis’.

Accept solver ’MAGNETICS’, analysis type ’2D or axisym Electromagnetics’ and solution type ’Magnetostatic’.

In ’Output Requests’, ’Table’, activate ’Total Force - entire (virtual)’. In ’2D’ activate ’Axisymmetric’.

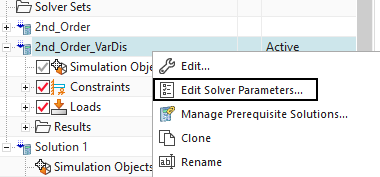

click RMB on the solution ’2nd_Order_VarDis’ and click ’Edit Solver Parameters’.

Under ’General’, switch ’Result Graphs (afu) to ’None’.

Under ’Parameter Sweep’, ’Perform’ assign ’One Parameter Sweep’. Continue as shown in the following window.

Explanation:

The ’Location of Expression’ is set to ’CAD Part’ because the location of the coil body will be variable.

Therefore we use ’Team23.prt’ for ’CAD Part Name’.

The ’Expression Name’ ist set to ’Gab’.

At last, the start position, the ’Step Size’ and the end position are defined.

Solve the ’VarDis’ solution.

Open the ’.VarDis.Force.txt’ file or export the table in

EXEL.

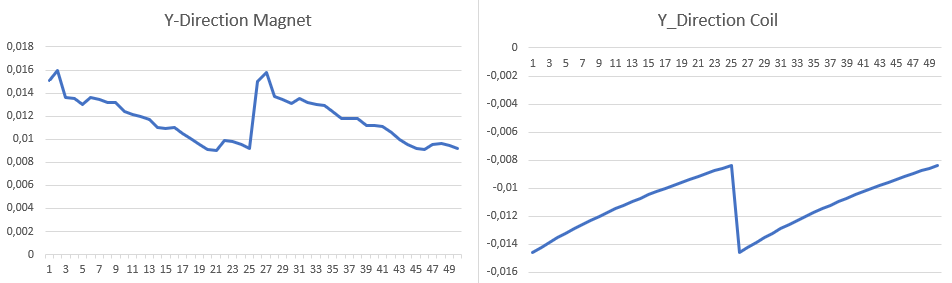

Following two plotted graphs of the forces in the Y-direction.

One can see that the force becomes smaller with greater distance. This

is because of the magnetic effect.