The 3 phase conductor system we analyse in this tutorial is loaded by either DC, AC or by a formula based short circuit condition. We want to analyse for the electromagnetic fields and mechanical deformations, stresses and reaction forces that result from said three load types.

Due to Amperes law, each conductor will create a rotating magnetic

field around himself, that also influences each other conductor. The

smaller the distance between them, the higher is this effect. In case

the conductors deform large, the distance between them will either

increase or decrease and thus, the produced fields will also change.

This nonlinear effect can be captured by bidirectional simulation: The

EM fields modify the geometry, the changed geometry results in a change

of the EM field. That type of simulation takes place if we activate

’Large Displacement’ in the Magnetics elasticity solver.

So, we will first create the Fem model with meshes and material

properties, nothing very special. Then we will create solutions for

electromagnetics with static (DC load), frequency (AC load) and

transient (short circuit load). For each solution we will add coupled

elasticity and finally we will run a solution with bidirectional

coupling and compare the results.

Estimated time: 1.5 h.

Follow the steps:

Download the model files for this tutorial from the following

link:

https://www.magnetics.de/downloads/Tutorials/8.CouplStructural/8.2ThreeConductors.zip

Open the file ’ThreeConductors.prt’.

Start Simcenter Pre/Post, Create a ’New Fem and Simulation’, use Solver MAGNETICS and Analysis Type ’3D Electromagnetics’. Switch off the ’Create Idealized Part’ and activate ’Non Manifold’. Create five solutions with the following types and names:

First solution:

Set type to ’Magnetostatic’, name ’MagStaDC_ElasSta’.

The name will show the characteristics of the used physics:

Electromagnetics will be set to static (MagSta) with direct current

(DC), elasticity will also be set to static (ElasSta). We will fill up

all solutions with details later.

Second solution:

Set type to ’Magnetodynamic Frequency’, name

’MagDynFreqAC50Hz_ElasSta’.

Set the ’Forcing Frequency’ to 50 Hz. So, we want to use a frequency

domain solution for electromagnetics with AC current at 50 Hz and a

steady state solution for the elasticity part.

Third solution:

Set the type to ’Magnetodynamic Frequency’, name

’MagDynFreqAC50Hz_ElasFreq’.

Set the ’Forcing Frequency’ to 50 Hz. The extension ’ElasFreq’ means

that we want to use a frequency response elasticity solution.

Forth solution:

Set the type to ’Magnetodynamic Transient’, name

’MagDynTrans_ShortCircuit’. We will use a transient solution for both

electromagnetics and elasticity. The current will be a short circuit

type.

Fifth solution:

Set the type to ’Magnetodynamic Transient’, name

’MagDynTrans_ShortCircuit_BiDir’. Same as above, but we want to activate

the bidirectional (’Large Displacement’) option.

Change the displayed part to the Fem file.

Verify the faces in group ’non-manifold-face’. There should be 12 faces in this group. Blank the air polygon body.

Mesh the ’Conductor1’ with hexa elements. Use the suggested

element size (6.32 mm). Activate ’Use layers’ and set the ’Number of

Layers’ to 30.

Edit the newly created mesh collector and his Physical. Set the

material to ’Built-In’ and choose ’Copper’ from the list. Check that in

box ’Elasticity Solution’ the option ’Active’ is on.

In the same way create meshes and Physicals for the remaining two conductors.

Unblank and mesh the air body. Use tetra elements and the suggested element size (129 mm).

Optionally, for high quality mesh transitions, create a ’Mesh Control’ with type ’Boundary Layer’ on the faces. If using mesh matings instead of non-manifold, activate the option ’Transition with pyramid elements’.

For the air mesh, create a ’FluidPhysical’ with ’Buit-In’

material ’Air’.

Change to the Sim file.

Blank all 3D collectors for easier visualization. Activate (double click) the ’MagStaDC_ElasSta’ solution.

Create a constraint of type ’Flux tangent (zero a-Pot)’ on all 9 outside faces. Also the 6 electrode faces of the 3 conductors must belong to this group. This constraint must be used in all solutions, so drag-drop it into the others. Blank the air body then.

Create a Voltage load: Set the type to ’On Solid Face’, key in 0 V and select the 3 electrode faces of the 3 conductors (no matter which side). This voltage load must be active in all solutions (all but the frequency solution), so drag-drop it into the such. For the frequency solution, create a separate one (’Voltage Frequency’) in the same way.

In the active solution ’MagStaDC_ElasSta’, create three ’Current’ loads as follows:

Set the type to ’On Solid Face’ and the ’Method’ to ’Harmonic (cos)’.

For ’Electric Current Amplitude’ key in 50000 A, for ’Frequency’ 50 Hz and for ’Phase Shift’ 0 degrees.

Select the electrode face of conductor 1. Click ’Apply’.

Create a similar load on the second conductor with a ’Phase Shift’ 120 degrees.

Create a similar load on the third conductor with a ’Phase Shift’ 240 degrees.

Activate solution ’MagDynFreqAC50Hz_ElaSta’ and create three ’Current Harmonic’ loads as follows:

Set the type to ’On Solid Face’ and the ’Definition’ to ’Amplitude/Phase’.

For ’Electric Current Amplitude’ key in 50000 A and for ’Phase Shift’ 0 degrees.

Select the electrode face of conductor 1. Click Apply.

Create a similar load on conductor 2 with a ’Phase Shift’ 120 degrees.

Create a similar load on conductor 3 with a ’Phase Shift’ 240 degrees.

Drag-drop these three loads also into solution ’MagDynFreqAC50Hz_ElasFreq’.

Activate solution ’MagDynTrans_ShortCircuit’ and create three ’Current’ loads with analytical formulas to describe the exponential behaviour of a short circuit as follows:

Set the type to ’On Solid Face’ and the ’Method’ to ’user-defined function’.

Key in the following formula:

Sqrt[2]*2e4*(Sin[2*Pi*50*$Time-1.57]+Exp[-$Time/0.0455]*Sin[1.57])

notice the ’1.57’ that appears two times: This describes the phase shift for the 3 phase current system.

Create a second and a third Current load on the electrodes faces of the second and third conductors. On the second, use a phase shift of 1.57+2*Pi/3 and on the third use 1.57+4*Pi/3

Drag-drop these three analytical loads into solution ’MagDynTrans_ShortCircuit_BiDir’.

Activate (double click) the ’MagStaDC_ElasSta’ solution.

Create a ’EM Elasticity Constraint’ on the first conductor. Set

the type to ’On Edges’ and select the shown two edges. Set all ’Degrees

of Freedom’ to ’Fixed’ and click OK.

For the remaining two conductors, create constraints in the same way. (it is also possible to put them all in one selection)

Drag-drop the three elasticity constraints into all other solutions.

Activate solution ’MagStaDC_ElasSta’.

In register ’Output Requests’ activate results as desired.

In register ’Coupled Elasticity’, set the ’Elasticity Solution’

to ’Steady State’ and activate the ’Output Requests’ as shown in the

picture below.

Solve the solution.

Display the Y displacement results. The maximum is 37.4 mm.

In frequency domain solutions all loads and results are assumed to be harmonic. So, all results oscillate between phase angle 0 (real part), angle 90 (imaginary part), 180 and 270. Therefore, also the resulting mechanical forces must be understood as oscillating. To use the forces in the following static elasticity solution, they are evaluated at phase angle 0 (Real part).

Activate solution ’MagDynFreqAC50Hz_ElaSta’.

In register ’Output Requests’ activate results as desired.

In register ’Coupled Elasticity’, set the ’Elasticity Solution’

to ’Steady State’ and activate the ’Output Requests’ as shown in the

picture below.

Solve the solution.

Check the resulting displacements. Set the ’Complex’ option to

’Real’ or ’At Phase Angle’ and the deformation scale to 1. The result is

37.7 mm, very near to the one from the static solution. The reason is

that the frequency is quite low, so results are nearly static. With

higher frequencies, skin effects would increase and results would

change.

Activate solution ’MagDynFreqAC50Hz_ElaFreq’.

In register ’Output Requests’ activate results as desired.

In register ’Coupled Elasticity’, set the ’Elasticity Solution’

to ’Frequency Response’ and activate the ’Output Requests’ as shown in

the picture below.

Solve the solution.

To check the resulting displacements, run a animation to see the

oscillation. Because displacements here are complex results (frequency

domain) the same rules apply as for EM results in frequency domain. To

animate, set in ’Post View’, register ’Deformation’ the ’Complex Option’

to ’At Phase Angle’ and the ’Scale’ to 1, ’Absolute’. Then use the

’Animation’, set ’Style’ to ’Modal’ and ’Full cycle’, then ’Play’.

The maximum displacements in this simulation are about 14 mm and thus much smaller than in the previous simulation, where we had 38 mm. A reason for this can be that the excitation frequency 50 Hz is away from the mechanical natural frequency of this conductor system. Such natural frequency can by found by a solve with NX Nastran solution 103. A nice additional training would be to find that natural frequency, apply the AC load at that frequency and find the displacements then again.

For the following two transient solutions we want to use a trick: We include the air body into the elasticity solution. By that way the air mesh will deform smoothly, forced by the conductors deformations. This trick leads to a nice air mesh at each time step even if large deformations appear (only the bidirectional solution is affected by this and thus, we could activate that only there). Of course, the air material needs as material properties a small value for Youngs modulus, Poisson ratio and Mass density. The very small Youngs modulus leads to deformations, but nearly no stresses in the air, so the conductor deformations are nearly not affected by this. As a disadvantage, solve time and memory consumption will increase, because of many more elements in the elasticity system.

Make the Fem part active.

Edit the Physical of the air and at ’Active in Solution’,

activate ’Elasticity’.

Optionally check that the air material has said mechanical properties (the Built-In Air has).

Make the Sim part active again.

Following we activate the elasticity solution:

Activate solution ’MagDynTrans_ShortCircuit’.

In register ’Output Requests’ activate results as desired.

In register ’Time Steps’, set the ’Time Increment’ to 0.05/25 and

the ’Number of Time Steps’ to 25.

In register ’Coupled Elasticity’, set the ’Elasticity Solution’

to ’Transient’ and activate the ’Output Requests’ as shown in the

picture below.

Solve the solution (takes about 3 min)

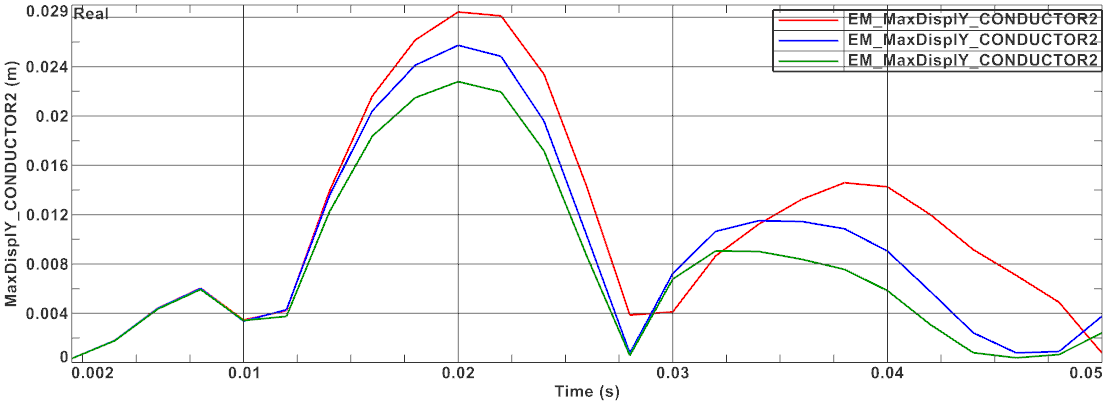

Display the three graphs showing the maximum conductor Y

displacements over time. As the following picture shows, the maximum

displacements are found at conductors 1 and 2 with about 29 mm.

We want to use the same settings as in the prior solution except one setting: The Large Displacement option will be active here (in prior versions, we called that ’Bidirectional’). This feature moves the nodes after each elasticity solve to the new positions.

Activate solution ’MagDynTrans_ShortCircuit_BiDir’.

In register ’Output Requests’ activate results as desired.

In register ’Time Steps’, again, set the ’Time Increment’ to 0.05/25 and the ’Number of Time Steps’ to 25.

In register ’Coupled Elasticity’, set the ’Elasticity Solution’

to ’Transient’. Activate ’Large Displacement’. Also activate the ’Output

Requests’ as shown in the picture below.

Solve the solution (about 3 min).

Display and compare the maximum Y conductor displacements of

conductor 2 of both Short Circuit solutions. As the following picture

shows, the large displacement (bidirectional) solution shows slightly

smaller displacements.

Display the displacements at time 0.02 sec (maximum, as seen above). Because in this simulation the bidirectional effect is active, now both effects are captured:

The EM field forces lead to mechanical deformations,

The increased distance leads to smaller EM fields.

The solution is more realistic: The distance between conductors 1 and

2 increases, but therefore the fields become smaller and this again

leads to a smaller distance.

To further increase accuracy, we can also run a simulation with the ’Strong Coupling’ feature. This performs an iterative loop updating both the electromagnetic and the elasticity solution at every time step until a residual tolerance is satisfied. This means that at each time step, some extra solves are done to correct any non-linear effects. Thus, results become more accurate and solve time increases.

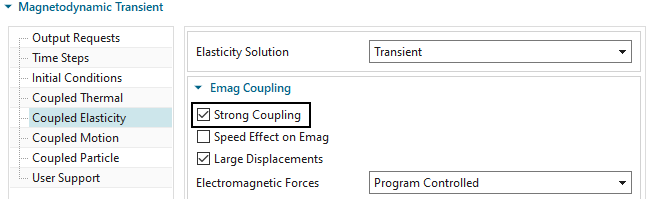

Clone the last solution. Rename it to ’MagDynTrans_ShortCircuit_BiDir_Strong’.

Edit the solution, in register ’Elasticity’ activate ’Strong

Coupling’.

Solve the solution (takes about 8 min)

Display and compare the maximum Y conductor displacements of

conductor 2 of all three Short Circuit solutions. As the following

picture shows, the strong coupling solution (green curve) differs from

the other two.

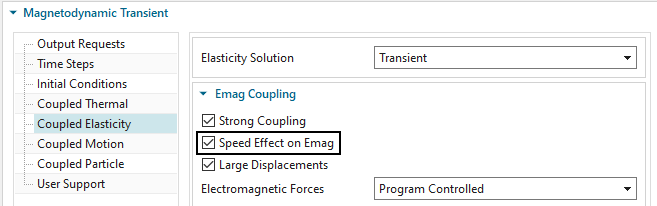

One final add-on can be done to increase accuracy: The speed effect should be activated because moving or oscillating conductors lead to damping forces. That means the lorentz forces will decrease slightly if conductors vibrate.

Clone the last solution. Rename it to ’MagDynTrans_ShortCircuit_BiDir_Strong_SpeedEffect’.

Edit the solution, in register ’Elasticity’ activate ’Speed

Effect on Emag’.

Solve the solution (takes about 8 min)

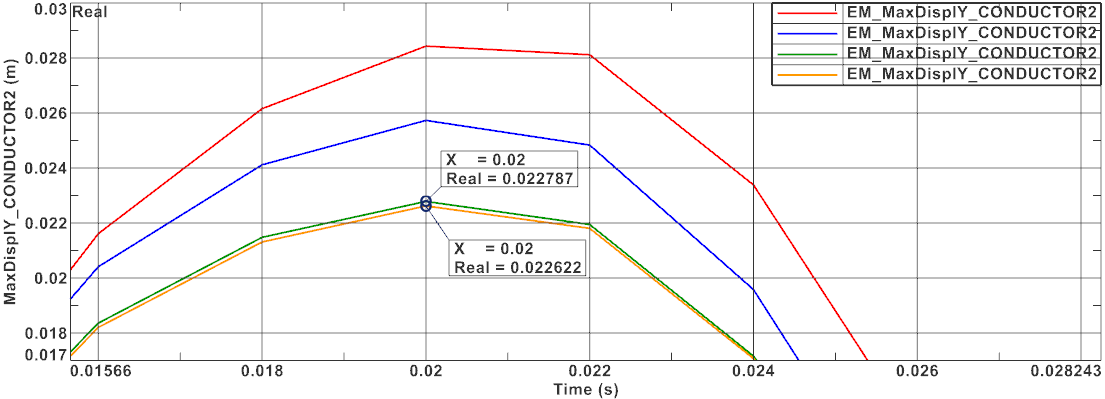

Display and compare the maximum Y conductor displacements of

conductor 2 of all four Short Circuit solutions. As the following

picture shows, the speed effect solution (orange curve) differs only

slightly from the before. It shows the smallest displacement result and

this is the most accurate and realistic.

The tutorial is finished.